Garbage conveying carriage easy to dump

A technology of garbage and carriages, which is applied in the field of easy-to-dump garbage transportation carriages, and can solve the problem of complete garbage dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

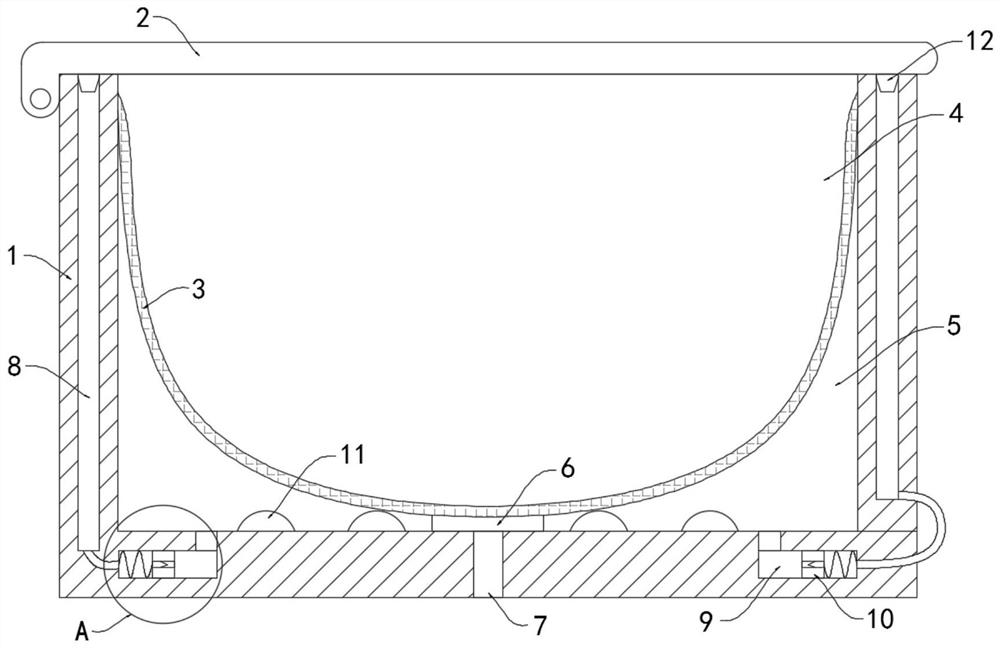

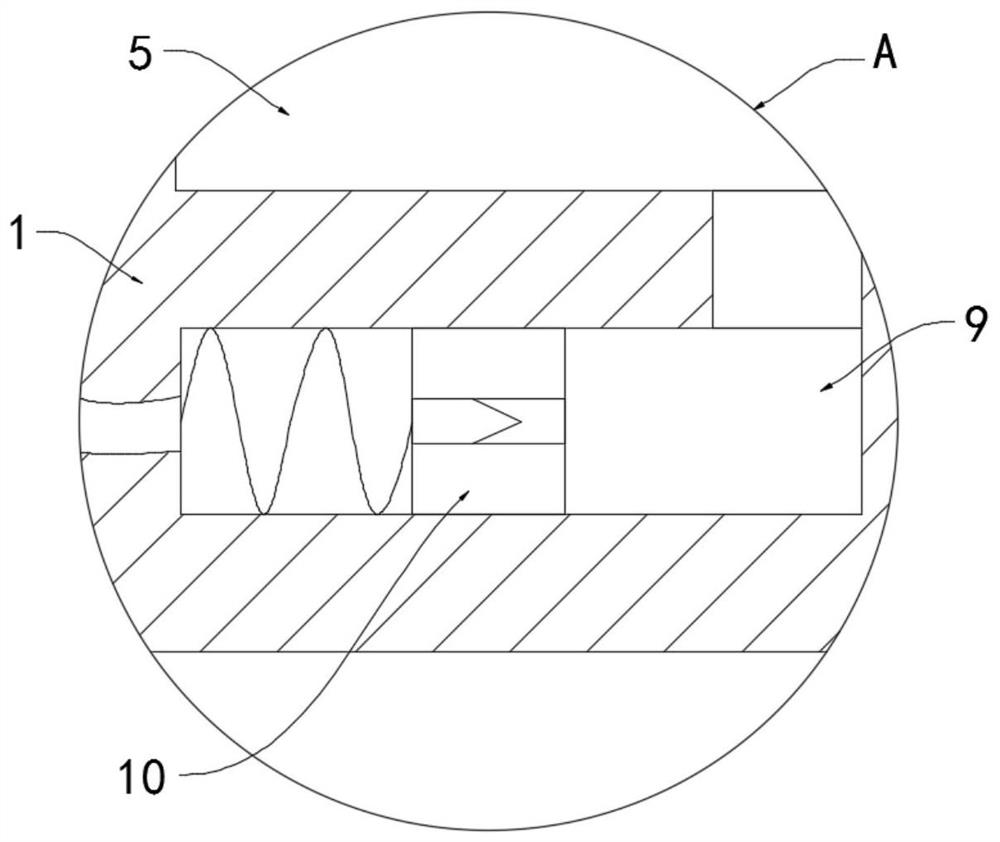

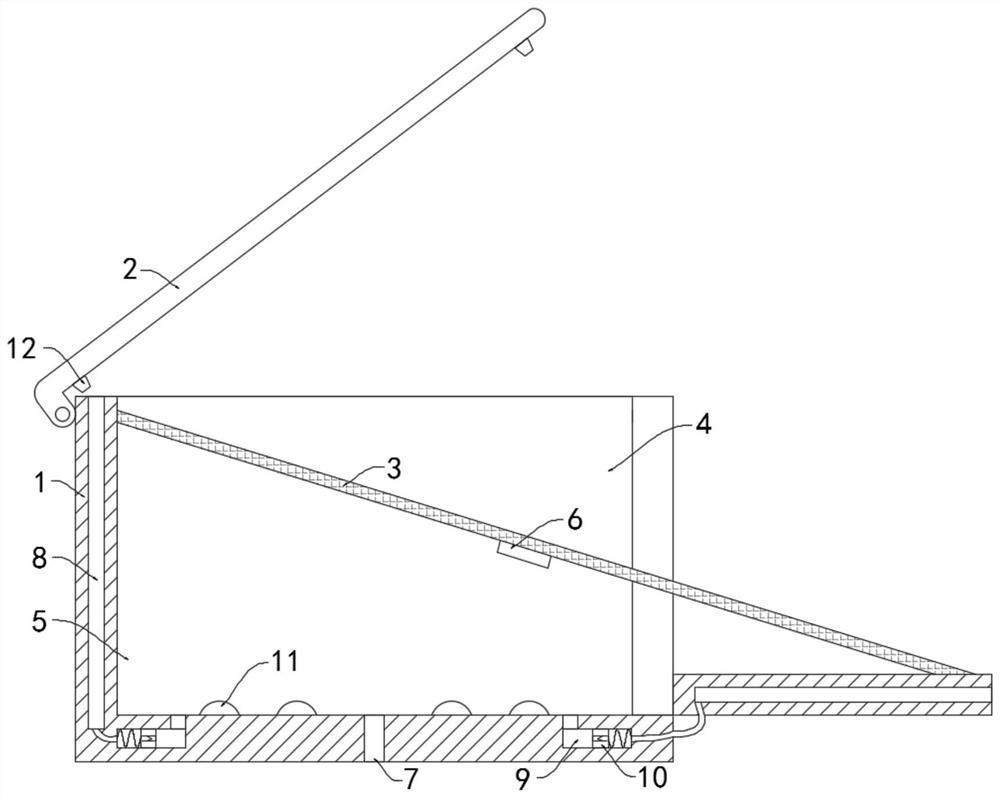

[0023] Such as Figure 1-3 As shown, an easy-to-dump garbage transport carriage includes a horizontally arranged box body 1. During use, the box body 1 is fixedly installed on the garbage transport vehicle. It is worth mentioning that the inner bottom surface of the box body 1 is fixedly installed with multiple Evenly arranged rolling balls 11, when the vehicle is running, the speed of the vehicle will cause the rolling balls 11 to generate inertia according to the change of road conditions. The rolling balls 11 can reduce the friction between the flexible loading layer 3 and the inner bottom surface of the box body 1, and reduce the flexible loading. Wear on the bottom of layer 3.

[0024] The outer wall of the box body 1 is rotatably connected with a box cover 2, the side wall at one end of the box body 1 is sealed and rotatably connected with the box body 1, and the upper port of the box body 1 is fixedly connected with a flexible loading layer 3, and the flexible loading l...

Embodiment 2

[0034] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the inner side wall of the case cover 2 is fixedly connected with an elastic layer 13, and the elastic layer 13 is placed with a magnetic ball 14 that attracts with the magnetic block 6 with different poles. It is mentioned that the elastic layer 13 contains magnetic powder 15 .

[0035] In this embodiment, the magnet ball 14 will roll back and forth in the elastic layer 13 under the action of inertia when the vehicle is running, and can press the garbage above the garbage, which can further increase the carrying capacity of the box body 1, and the magnet powder 15 will The gravitational force of the magnetic block 6 acts as a downward force on the elastic layer 13, further squeezing the rubbish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com