Dense single-layer sectional treatment method and treatment device for high-pressure under-injection well

A treatment method and treatment device technology, which is applied in the direction of wellbore/well valve devices, chemical instruments and methods, earthwork drilling and production, etc., can solve the problems of short effective period of measures, so as to improve water flooding efficiency, prolong the effect of measures, improve Effect of water injection profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

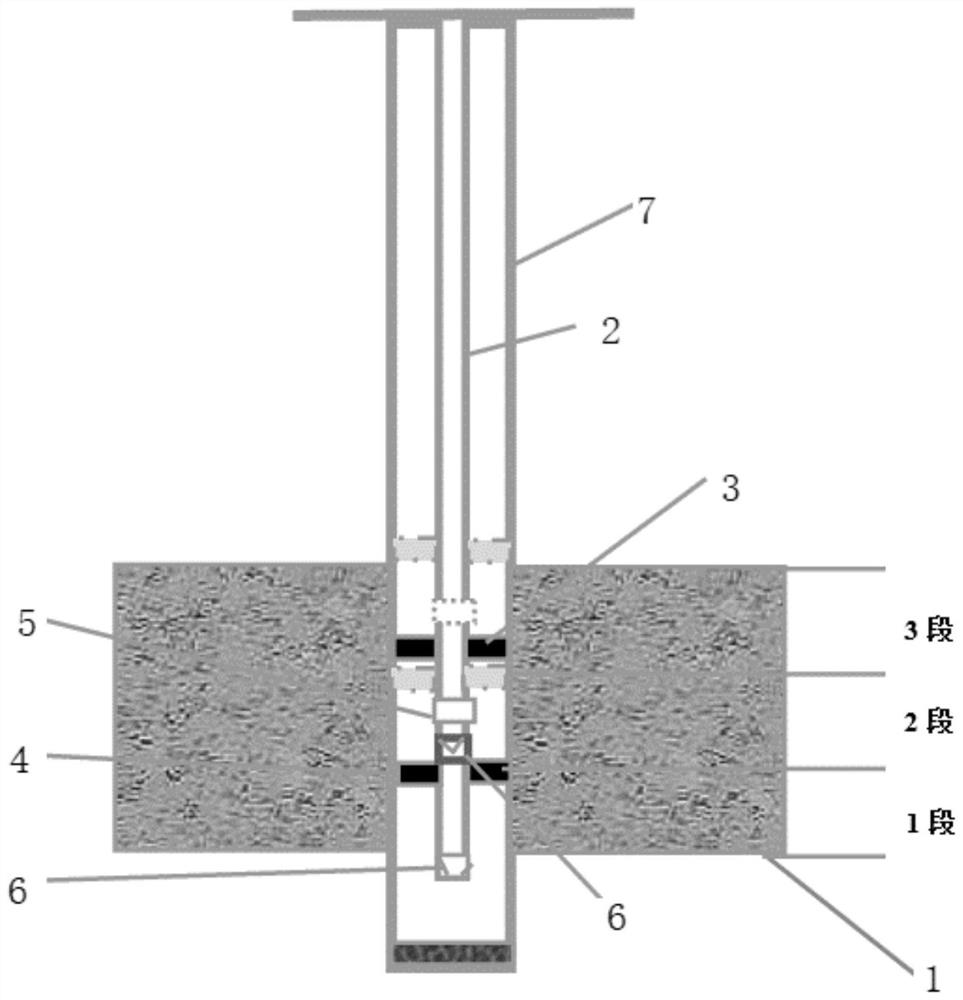

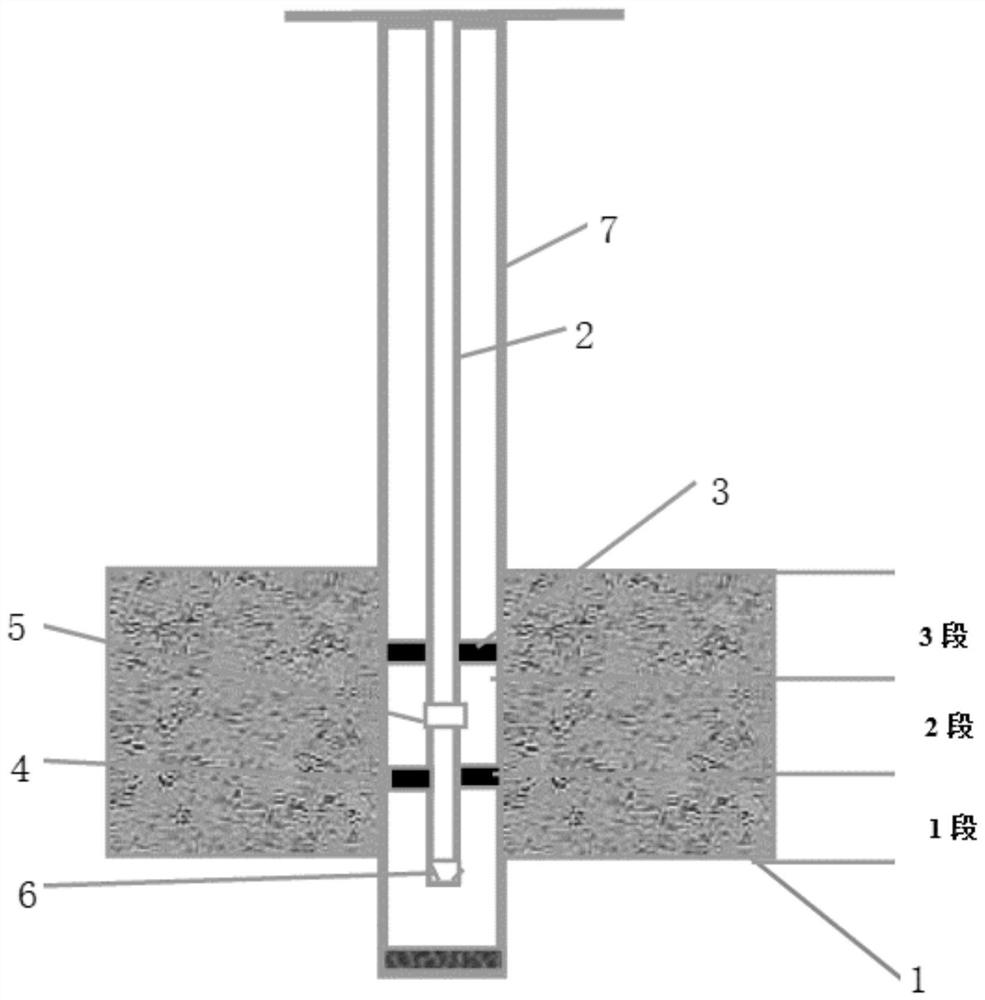

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

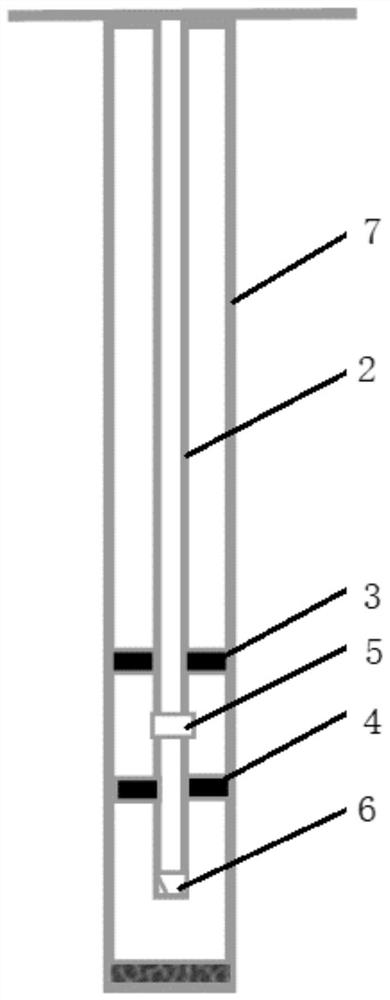

[0037] refer to figure 1 , a dense single-layer staged treatment device for water injection wells, comprising a construction string 2, an upper packer 3, a lower packer 4, a constant pressure valve 5 and a ball valve 6.

[0038] The upper packer 3 and the lower packer 4 are arranged at intervals on the construction pipe string 2, the constant pressure valve 5 is arranged on the construction pipe string 2, and is located between the upper packer 3 and the lower packer 4, and the ball valve 6 Set at the lower end of the oil pipe.

[0039] The above-mentioned ball valve 6 includes a ball seat and a closed ball. When the plugging solution is injected into the lowermost end of the oil layer, the ball valve 6 is opened, that is, the closed ball is separated from the ball seat. When the ball v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com