Blade structure of a drying drum

A technology of blade structure and drum, which is applied in drying, drying solid materials, lighting and heating equipment, etc., can solve the problems of affecting thermal efficiency, sticking of lifting blades, and easy bonding on dead corners, so as to improve thermal efficiency and reduce The effect of mud content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below with reference to the accompanying drawings and through specific embodiments.

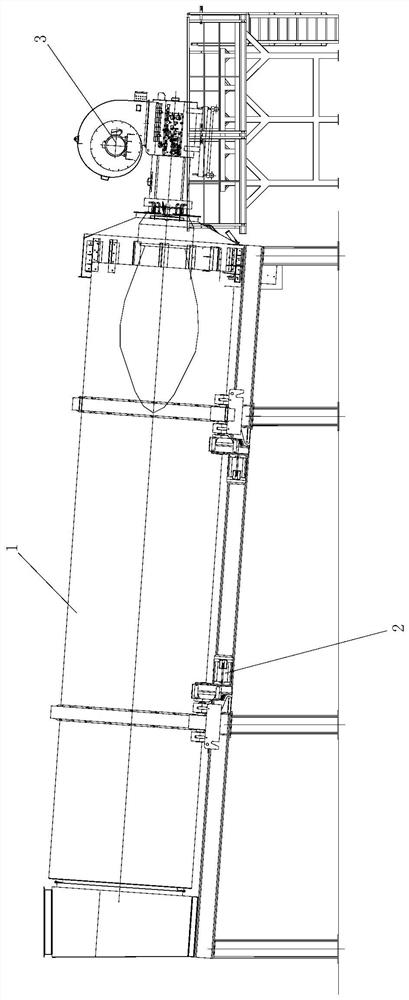

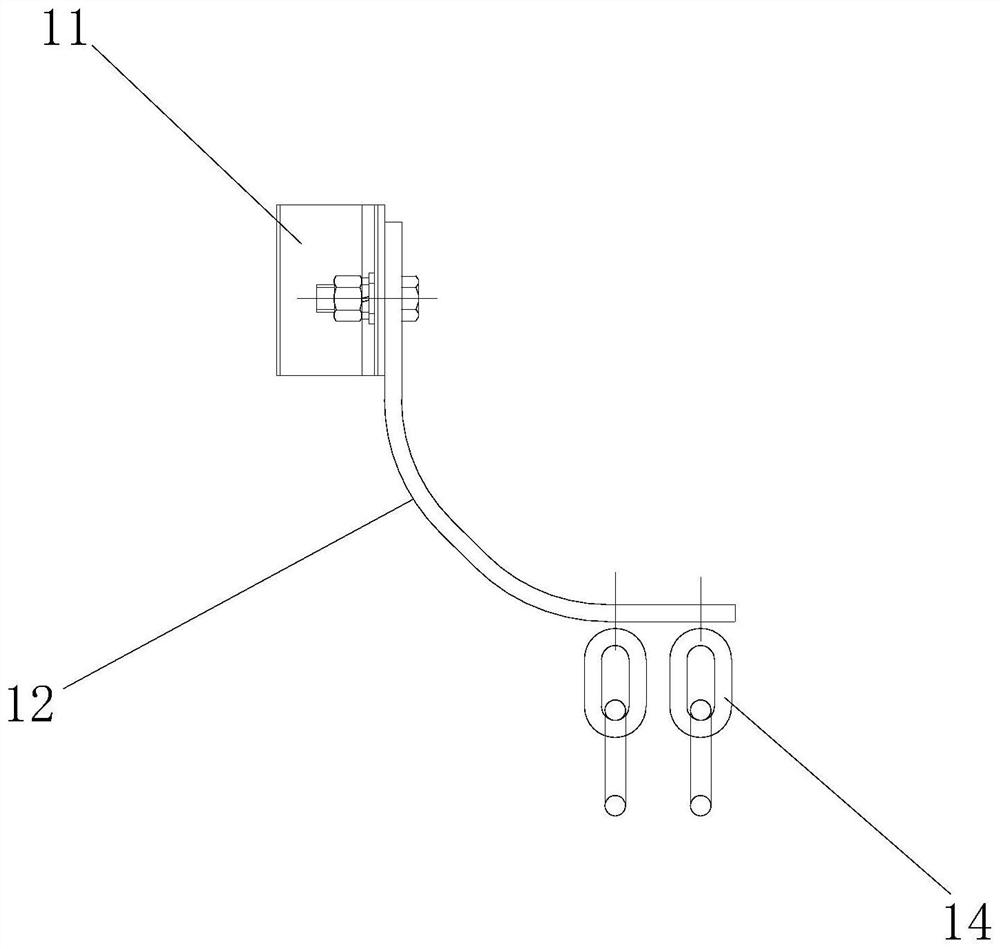

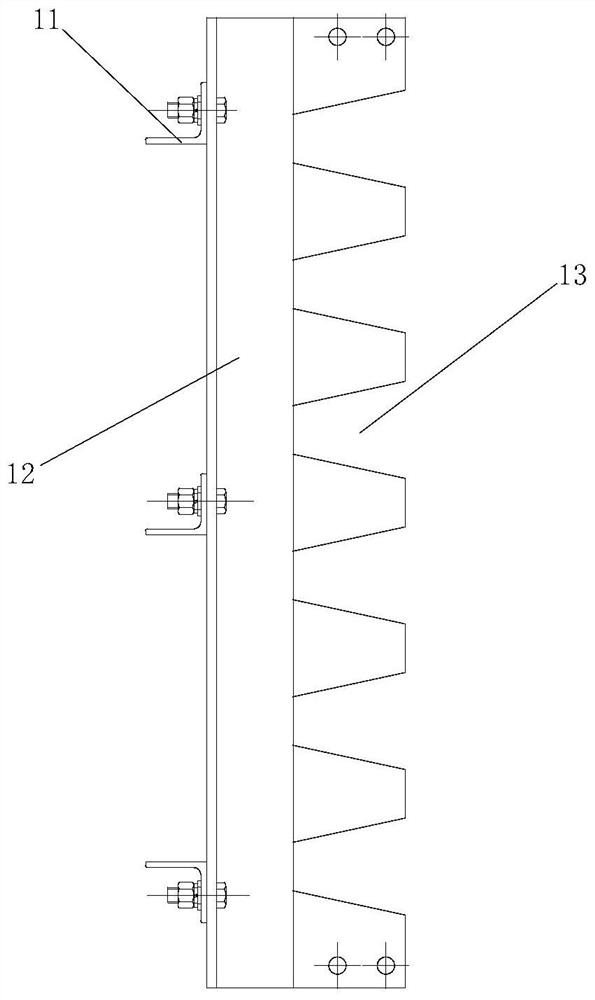

[0032] A blade structure of a drying drum, such as Figure 1-Figure 11 As shown, it includes a number of tooth-shaped material-lifting blades and a number of cradle-type material-containing blades connected to the inner wall of the drum 1 in an annular array; the tooth-shaped material-lifting blades are located on the side near the feeding end of the drum 1, The cradle-type material-containing blade is located on the side close to the discharge end of the drum 1 .

[0033] Further, the outer wall of the drum 1 is connected with a rolling ring; the rolling ring is matched with the driving mechanism 2 arranged on the frame, the driving mechanism is a deceleration motor, and the output end of the deceleration motor is connected with a supporting wheel, so The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com