Ultrasonic fatigue stress amplifying device with unified sample size

A fatigue stress and amplifying device technology, applied in measuring devices, using repetitive force/pulse force to test the strength of materials, instruments, etc., can solve the problems of low performance, poor stability and accuracy, and achieve good performance and operation. Convenient and adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

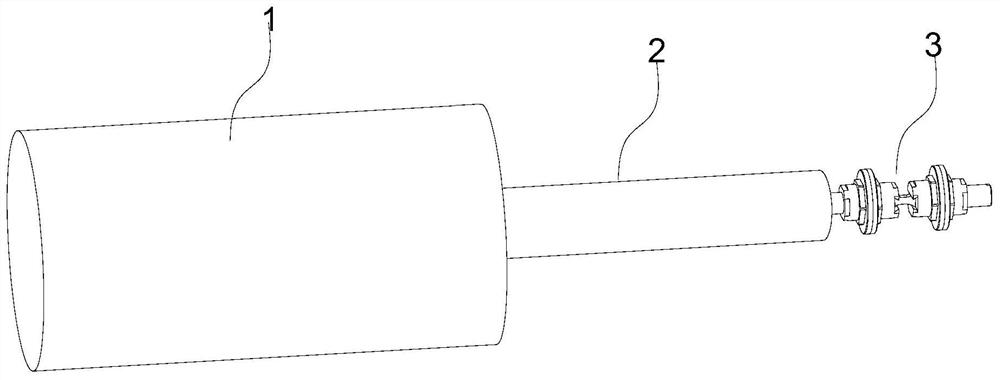

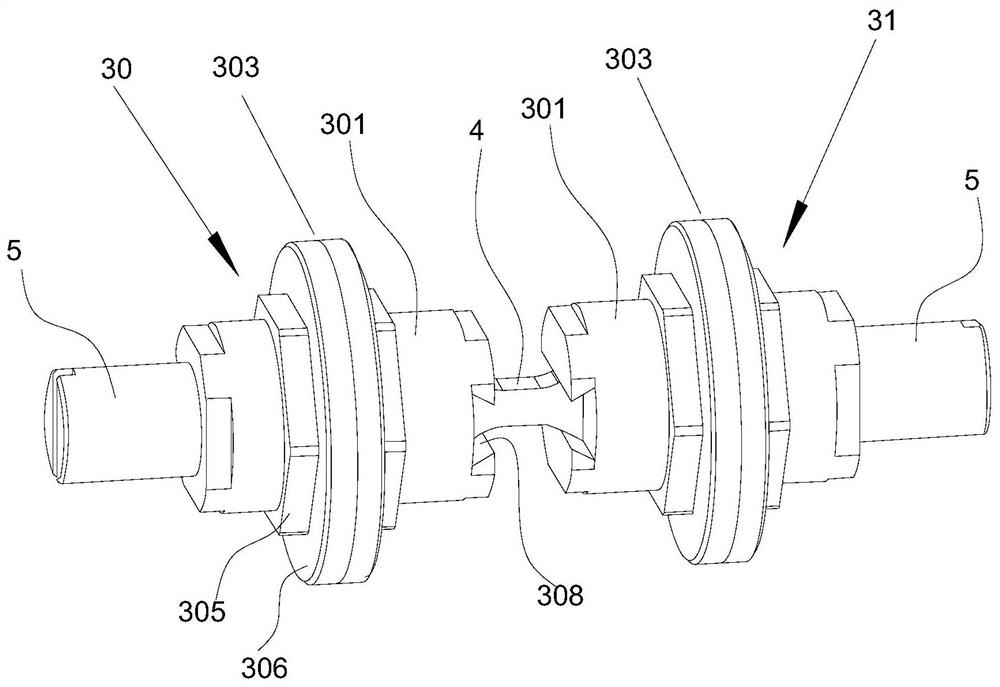

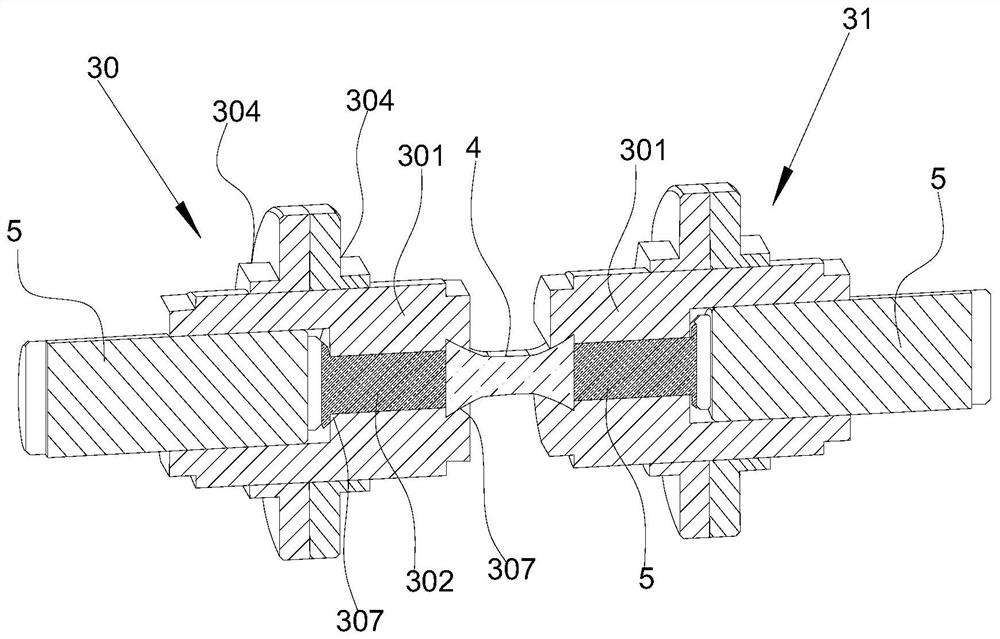

[0021] Such as Figure 1 to Figure 3 As shown, an ultrasonic fatigue stress amplification device with a uniform sample size includes an ultrasonic transducer 1, an extension rod 2 axially mated and connected to the end of the ultrasonic transducer 1, and an extension rod 2 connected to the extension rod 2 away from the ultrasonic transducer The adjustable stress amplification mechanism 3 at the end of the device 1. The ultrasonic transducer 1 converts electromagnetic energy into sound energy. The ultrasonic transducer 1 and the extension rod 2 are connected through M12 threads to meet the first-order vibration frequency in the axial direction. The extension rod 2 and the adjustable stress amplification mechanism 3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com