Sand-discharge oil production method and equipment

A wellhead device and oil layer technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problem that the top and bottom of the packer cannot be connected, the mixed fluid flow rate is slow, and the oil well casing pressure and dynamic fluid level data cannot be recorded. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

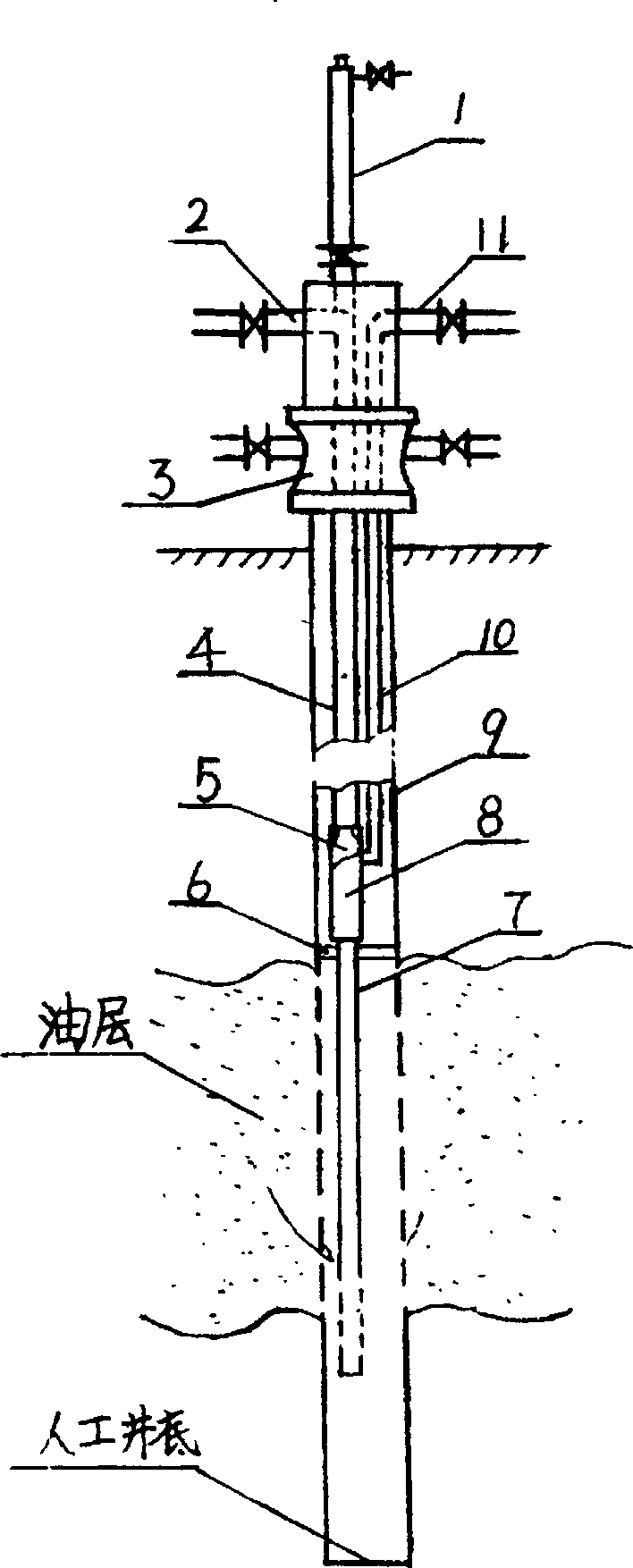

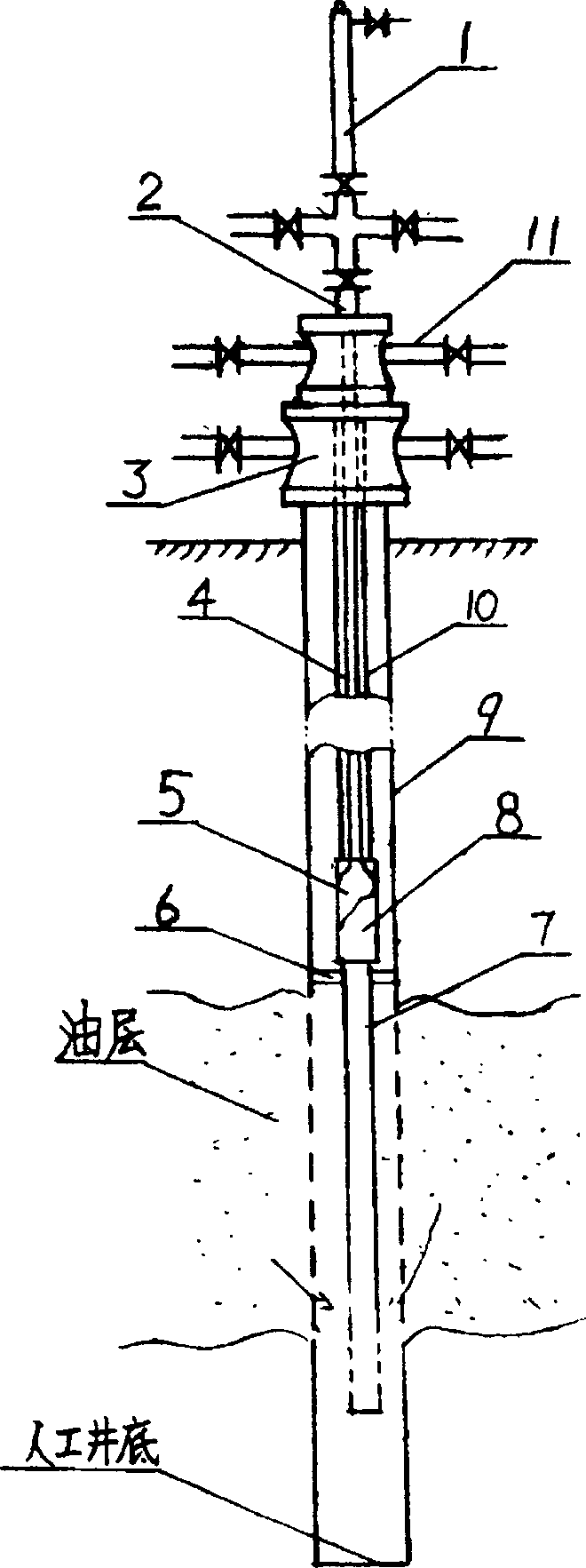

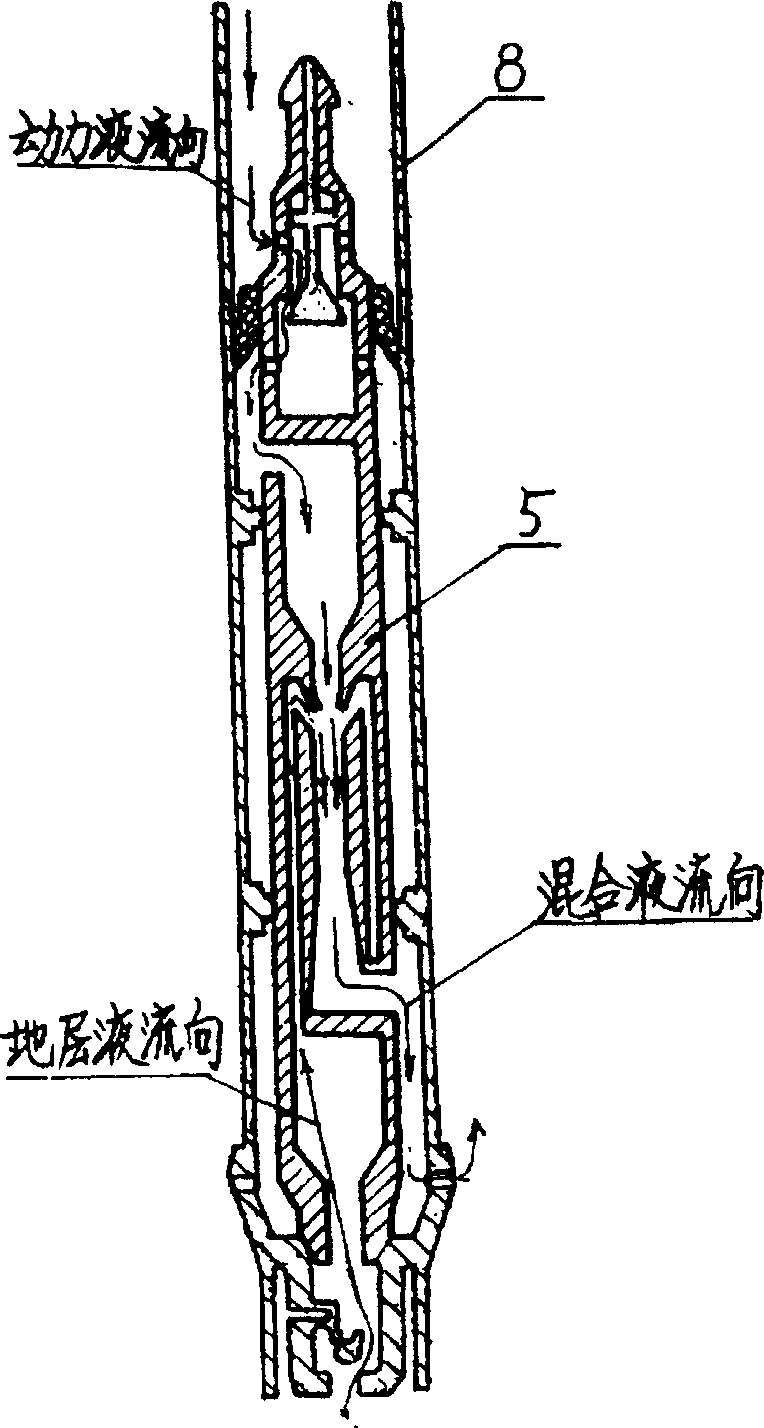

[0012] As shown in the accompanying drawings, a sand discharge oil production device of the present invention has a wellhead (3) with a flow channel, and the power fluid inlet (2) on the wellhead passes through the flow channel and the wellbore (9) in the wellhead. The downhole power fluid pipe (4) in the wellhead is connected, the mixed fluid outlet (11) on the wellhead device is connected with the downhole mixed fluid pipe (10) in the wellbore through the flow channel in the wellhead device, and the downhole power fluid pipe and the downhole mixing fluid The liquid pipe is connected with the hydraulic jet pump (5) in the pump barrel (8), and the cross-sectional area of the flow path of the downhole mixed liquid pipe is small, so that the flow rate of the mixed liquid containing sand is far greater than the sedimentation velocity of sand produced in the reservoir. It flows upward through the wellhead device to the ground to prevent sand production and settlement in the reser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com