Strip breakage alarm device for modified plastic production

An alarm device, alarm device technology, applied in the direction of alarms, signal devices, visible signal devices, etc., can solve the problems of dust falling, inability to adjust the angle of the alarm device body, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

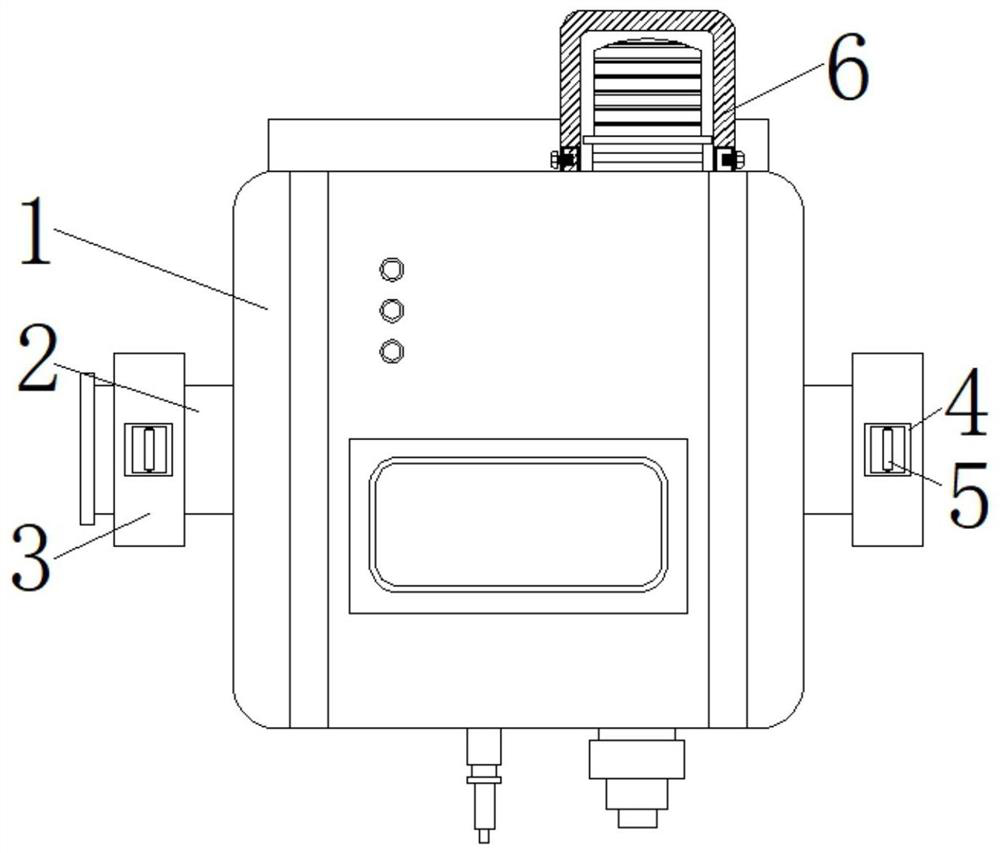

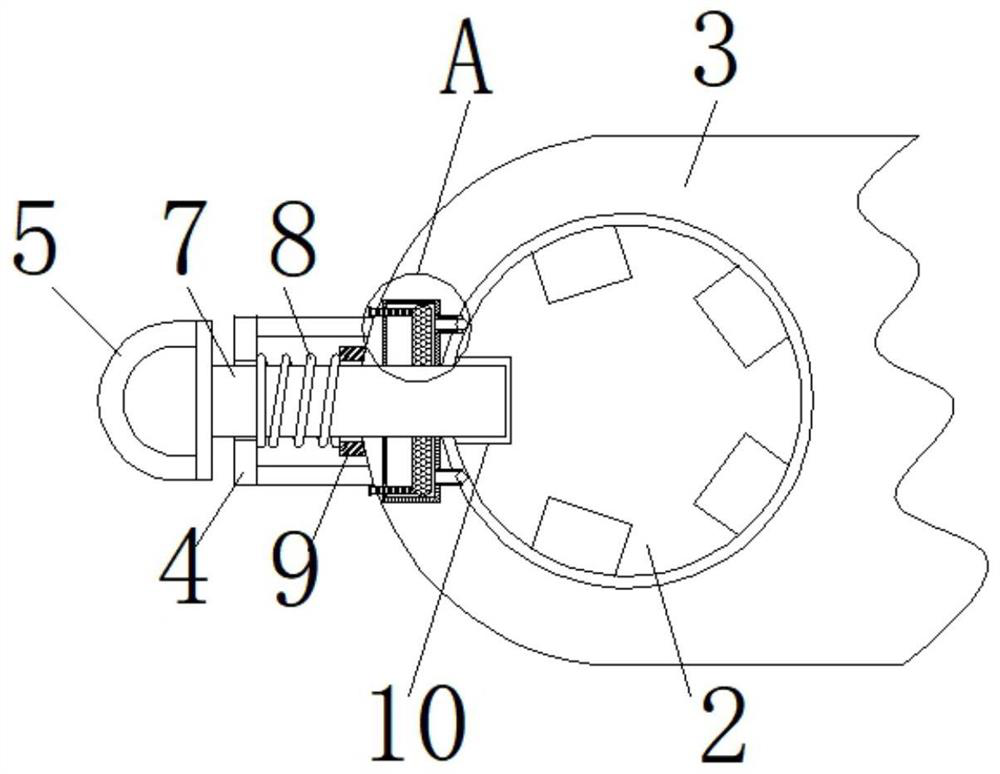

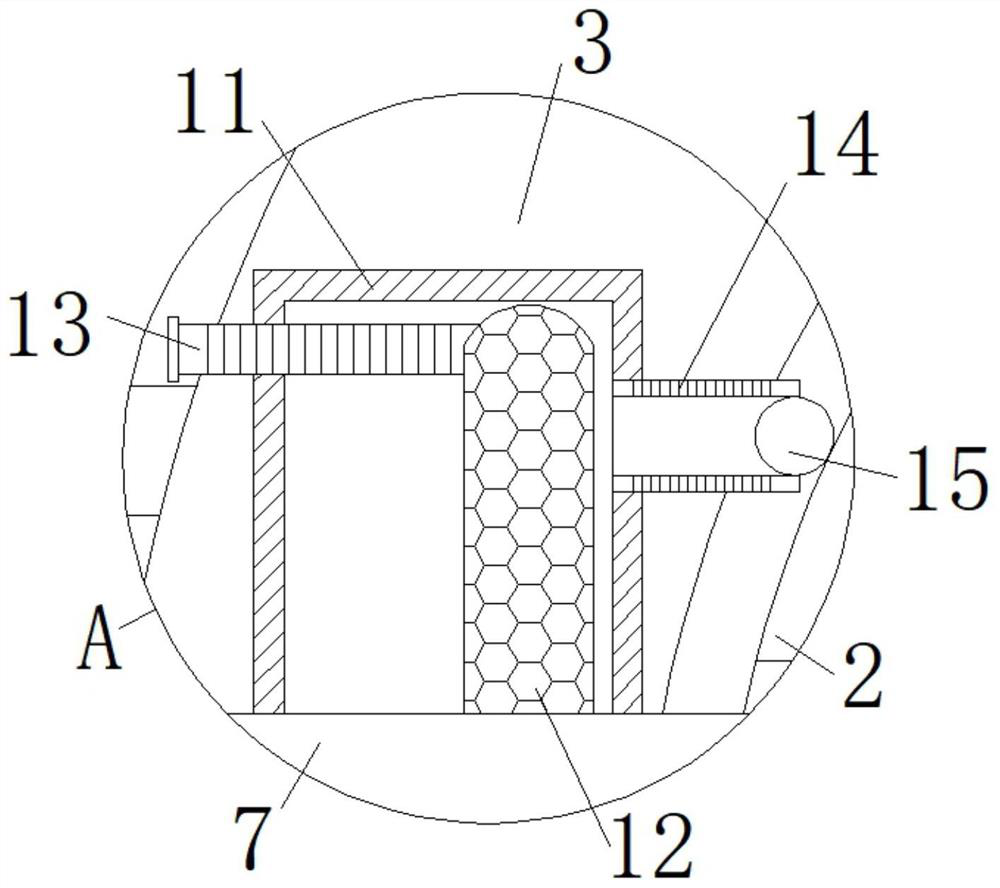

[0027] Please refer to figure 1 , figure 2 , image 3 As shown, the present invention provides an alarm device for broken strips produced by modified plastics, including an alarm device body 1, a fixed rotating shaft 2 is fixed on both sides of the alarm device body 1, and a mounting frame 3 is provided for rotation adjustment on the outer surface of the fixed rotating shaft 2 , the front end of the mounting frame 3 is fixed with a fixed frame 4, the front end of the mounting frame 3 is fixed on the inner side of the fixed frame 4, and a sealing rubber pad 9 is fixed, and the connection between the fixed frame 4 and the sealing rubber pad 9 is fixed with a connecting spring 8, and the connecting spring 8 The inner circle of the inner circle is movable through a bolt 7, the bolt 7 extends to the outer wall of the fixed frame 4 and the top is fixed with a pull ring 5; the outer surface of the fixed shaft 2 is provided with several groups of equally spaced card slots 10, and th...

Embodiment 2

[0031] Please refer to figure 1 , Figure 4 , Figure 5As shown, the present invention provides a kind of alarm device for broken bars produced by modified plastics, comprising an alarm device body 1, the top of the alarm device body 1 is fixed with a protective cover 6; The bottom surface is provided with a sliding groove 16 engaged with the sliding block 17 , the side surface of the protective cover 6 is threaded with a fixing bolt 18 , and the side surface of the sliding block 17 is provided with a thread groove 19 for limiting the fixing bolt 18 .

[0032] The surface of the alarm device body 1 is coated with an inorganic nano-corrosion layer, and the surface of the inorganic nano-corrosion layer is coated with a chromium carbide wear-resistant layer; the surface of the mounting frame 3 is coated with a chromium carbide wear-resistant layer, and the shape of the mounting frame 3 is "U". ” shape; the shape of the protective cover 6 is an inverted “U” shape, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com