Photovoltaic module glue overflowing groove frame

A technology of photovoltaic modules and overflow glue tanks, applied in the field of photovoltaics, can solve the problems of difficult control of the amount of silica gel, poor sealing effect, and reduced service life of components, so as to achieve the effect of reducing usage and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

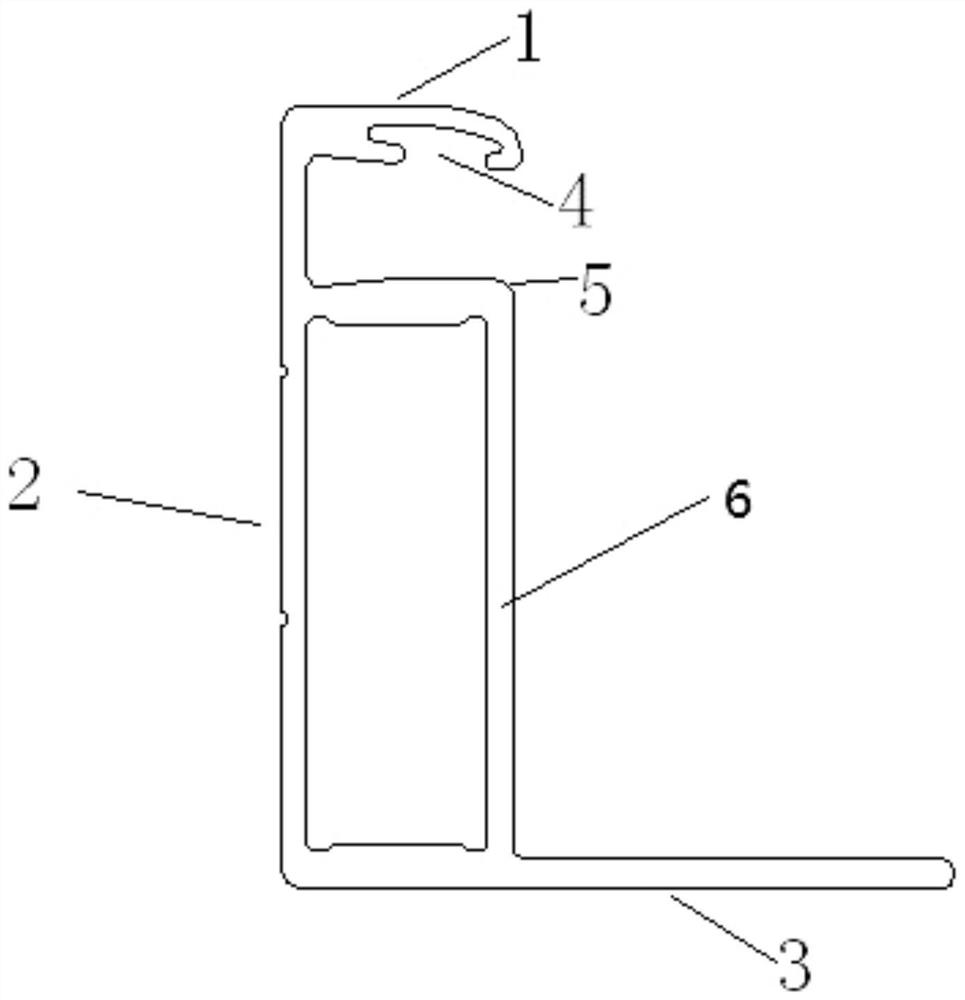

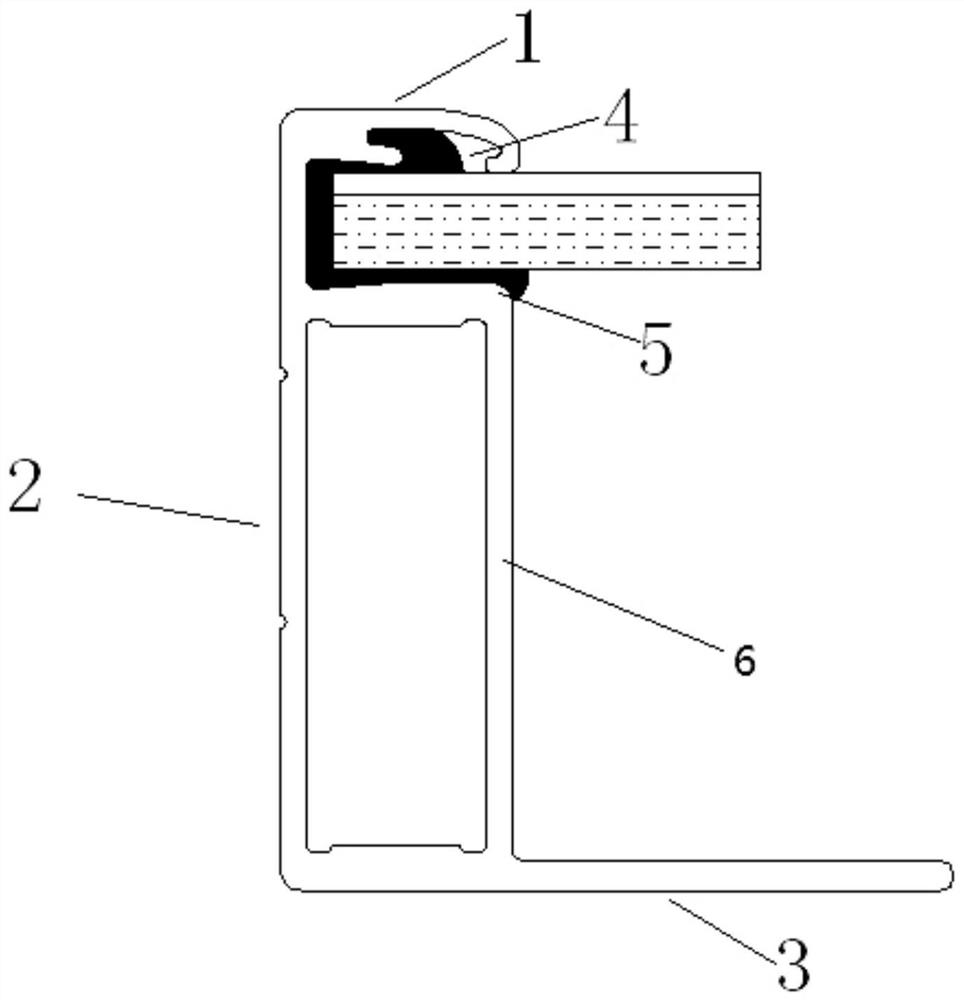

[0020] Such as Figure 1-2 As shown, a photovoltaic module overflow groove frame includes a frame body 1, a frame body 6 includes a frame A side 1, a frame B side 2, a frame C side 3, a glue overflow groove 4 and a sealing port 5, and a frame A side 1 The inner side of the inner side is provided with a glue overflow groove 4, and the glue overflow groove 4 notch and the inner side of the cavity are provided with a glue sealing port 5.

[0021] Preferably, one end of the frame A side 1 is vertically connected to one end of the frame B side 2 .

[0022] Preferably, one end of the frame B surface 2 is vertically connected to one end of the frame C surface 3 .

[0023] Preferably, the frame A surface 1 and the frame C surface 3 are parallel to each other.

[0024] Preferably, the thickness of the side B of the frame is 1.2mm.

[0025] Preferably, the C-side 3 of the frame has a width of 30mm and a thickness of 1.2mm.

[0026] Preferably, the frame body 6 is an integrally forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com