Continuously variable transmission control device and control method

一种无级变速器、控制装置的技术,应用在传动装置控制、带有齿的元件、皮带/链条/齿轮等方向,能够解决驾驶员不舒服等问题,达到防止感到不舒服的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

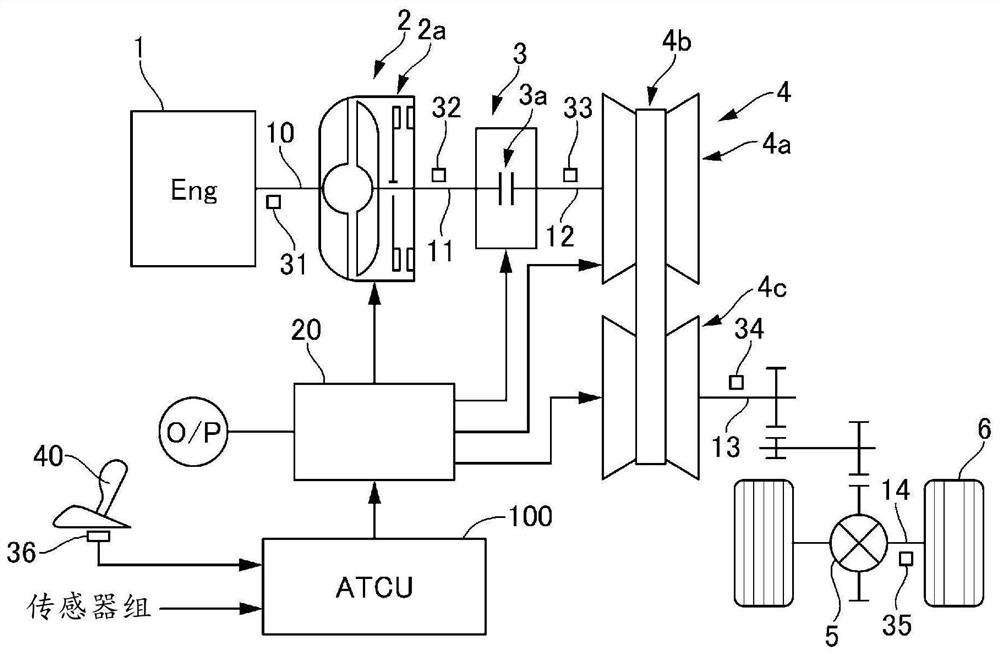

[0015] figure 1 It is a schematic diagram showing the structure of the continuously variable transmission of the embodiment. The continuously variable transmission changes the speed of rotation output from the engine 1 and transmits it to the drive wheels 6 . The continuously variable transmission has: a hydraulic torque converter 2 , a forward and reverse switching mechanism 3 , a transmission mechanism 4 , and a differential gear 5 . The torque converter 2 has a lock-up clutch 2 a directly connected between an engine output shaft 10 connected to the engine 1 and a turbine shaft 11 . The forward / reverse switching mechanism 3 has: a planetary gear set, and a hydraulic actuator, that is, two frictionally engaged main components (a forward clutch to achieve a forward state through engagement, and a reverse clutch to achieve a reverse state through engagement). Hereinafter, these two frictional engagement main components are collectively referred to as a clutch 3a.

[0016] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com