Butt clamp type double-row cotton stalk pulling-out device

A technology of cotton stalks and opposite sides, which is applied in the field of clip-type double-row cotton stalk removal devices, which can solve the problems of high labor intensity, waste of natural resources, and high cost, so as to improve work efficiency, facilitate agricultural operations, and reduce the extraction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

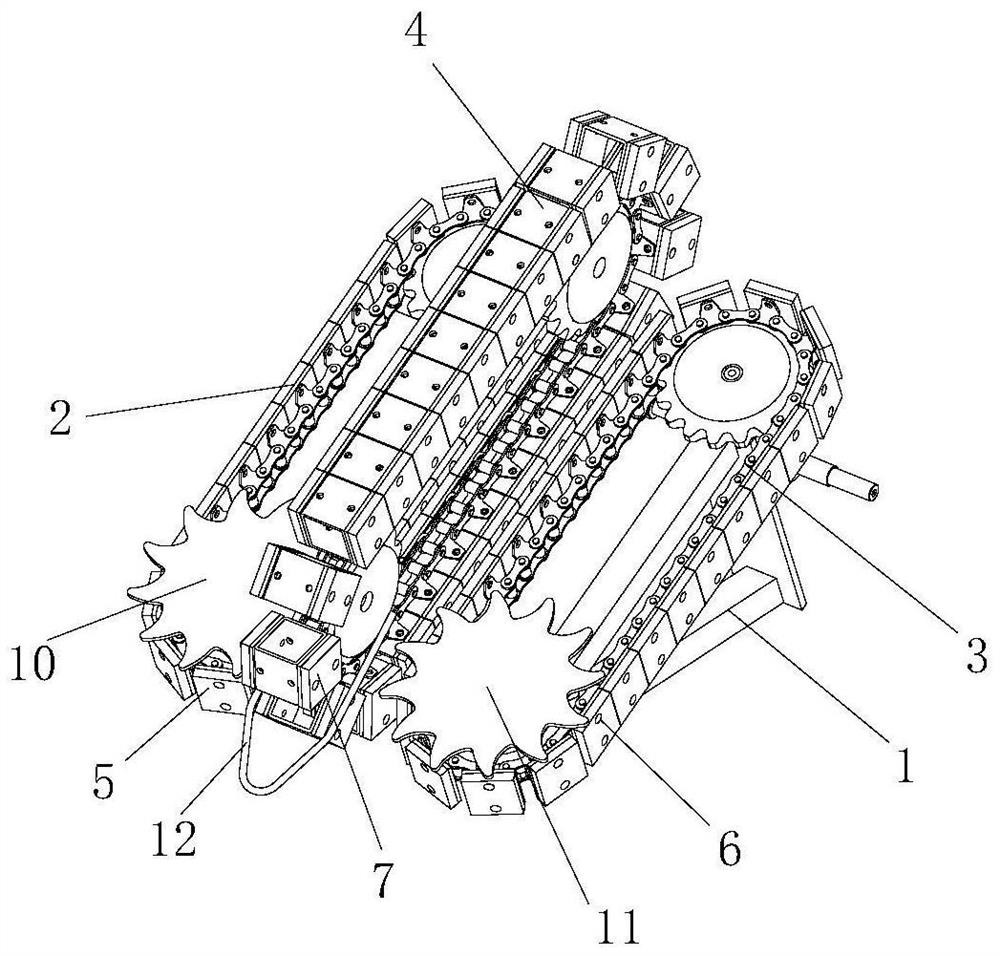

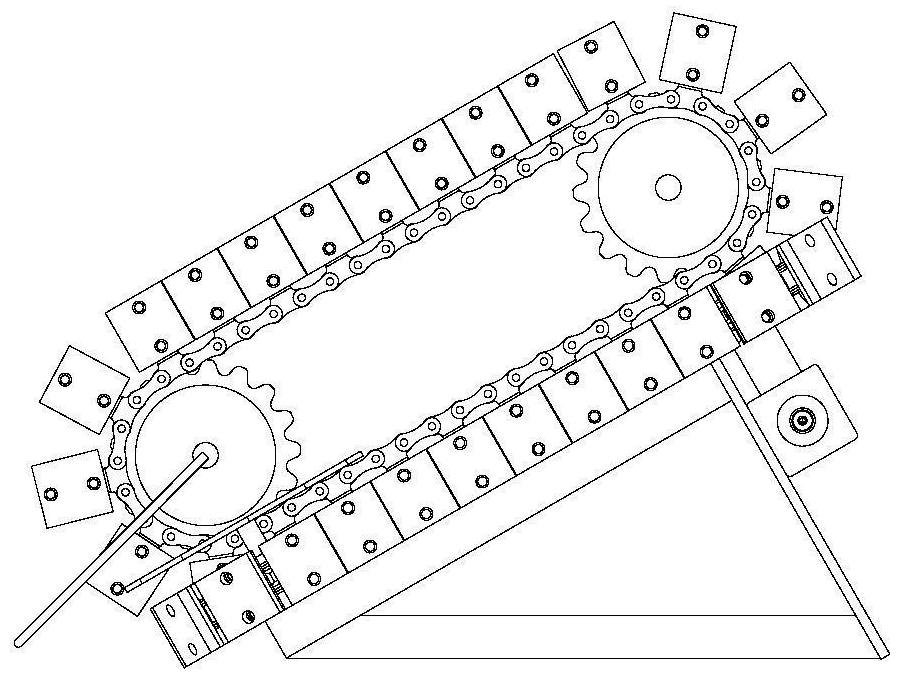

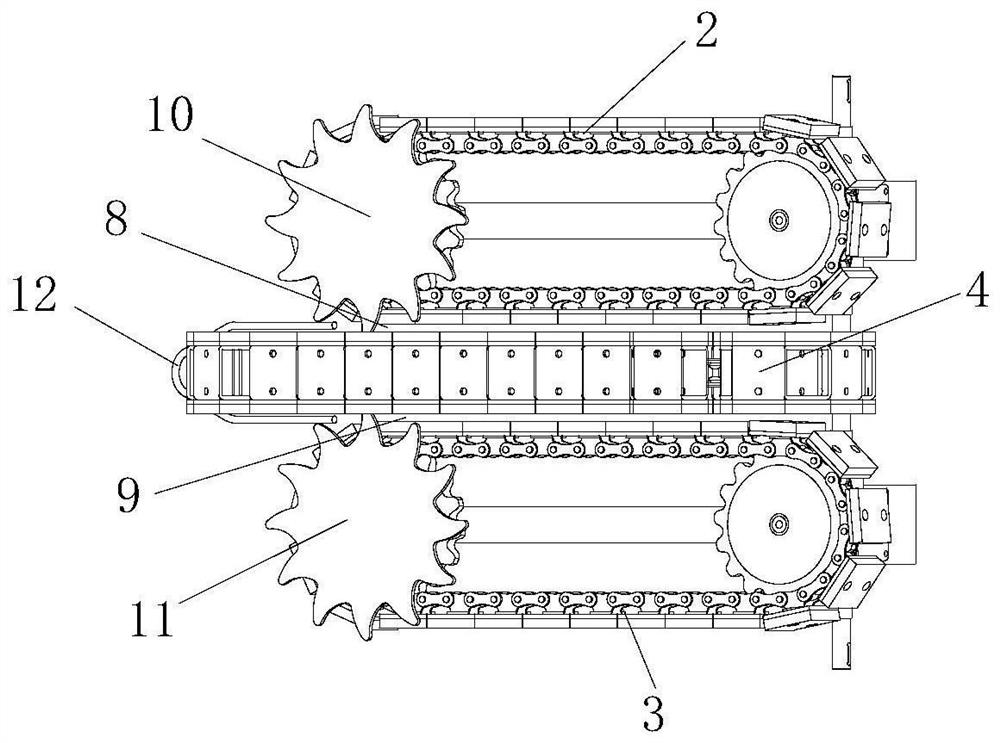

[0021] The double-row cotton stalk plucking device of this embodiment, such as Figure 1-4 As shown, it includes a frame 1, a left chain transmission mechanism 2, a right chain transmission mechanism 3, and a middle chain transmission mechanism 4. The left chain transmission mechanism 2, the right chain transmission mechanism 3 are all set on the machine at a preset inclination angle to the horizontal plane. On the frame 1, the intermediate chain transmission mechanism 4 is vertically arranged on the frame 1, and the bottom of the intermediate chain transmission mechanism 4 is consistent with the horizontal inclination angle of the left chain transmission mechanism 2 and the right chain transmission mechanism 3. In specific implementation, the left chain transmission mechanism 2 and the right chain transmission mechanism 3 are preferably symmetrical with respect to the middle chain transmission mechanism 4.

[0022] Such as Figure 1-5 As shown, each outer chain plate of the left ...

Embodiment 2

[0031] The difference between this embodiment and the first embodiment is as follows: Figure 6-8 As shown, the left feeding mechanism and the right feeding mechanism in this embodiment adopt a passive feeding method, that is, the left feeding mechanism and the right feeding mechanism are both bell-mouth-shaped feeding mechanisms made of metal strips , The bell mouth narrows from the front to the back. In addition, the middle metal strip 15 on the adjacent side of the left feeding mechanism and the right feeding mechanism is made into one body, which also has the following functions: First, the left feeding mechanism and the right feeding mechanism can be separated to facilitate separate feeding. Into the cotton stalks of different rows, the second is to prevent the cotton stalks from entering the gap between the left feeding mechanism and the right feeding mechanism, and reduce the cotton stalk pulling rate.

[0032] In addition, it should be noted that the left chain transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com