Stone machining equipment

A stone processing and equipment technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as excessive grinding of stone surface, affecting the effect of stone surface polishing, etc., to improve quality and efficiency, improve quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

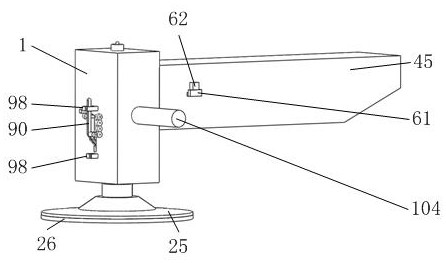

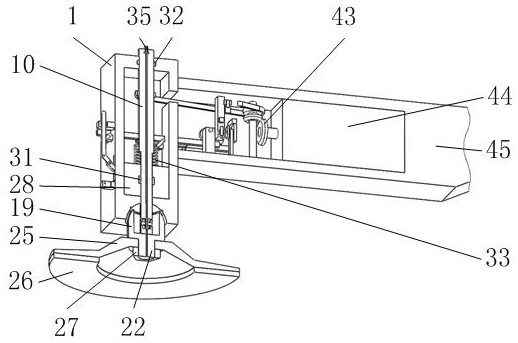

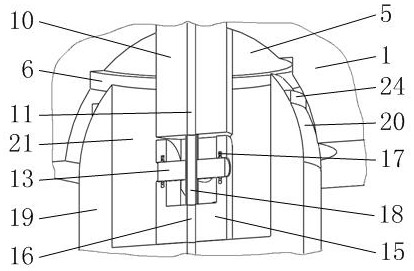

[0046] The accompanying drawings are schematic diagrams of the implementation of the present invention, so as to facilitate the understanding of the operation principle of the structure. The specific product structure and proportions can be determined according to the use environment and conventional techniques.

[0047] like figure 1 , 2 As shown, it includes a head case 1, a telescopic shaft 10, a spring A33, a cross shaft 13, a connecting column 15, a scroll spring 17, a mounting head 19, a ring A24, a disc seat 25, a grinding disc 26, and a nut 27, among which, as shown in the figure figure 2 As shown, the outer shaft of the telescopic shaft 10 is rotatably matched with the head casing 1, and the inner shaft of the telescopic shaft 10 is circumferentially rotated and axially slidably fitted with the head casing 1; image 3 , 19 , 20, a connecting column 15 is installed in the circular groove C21 at the upper end of the cylindrical mounting head 19, and the connecting c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap