Novel power battery pack fixing and mounting structure

A power battery pack and installation structure technology, which is applied in the direction of power devices, electric power devices, transportation and packaging, etc., to achieve the effect of low mold opening cost and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with specific embodiment:

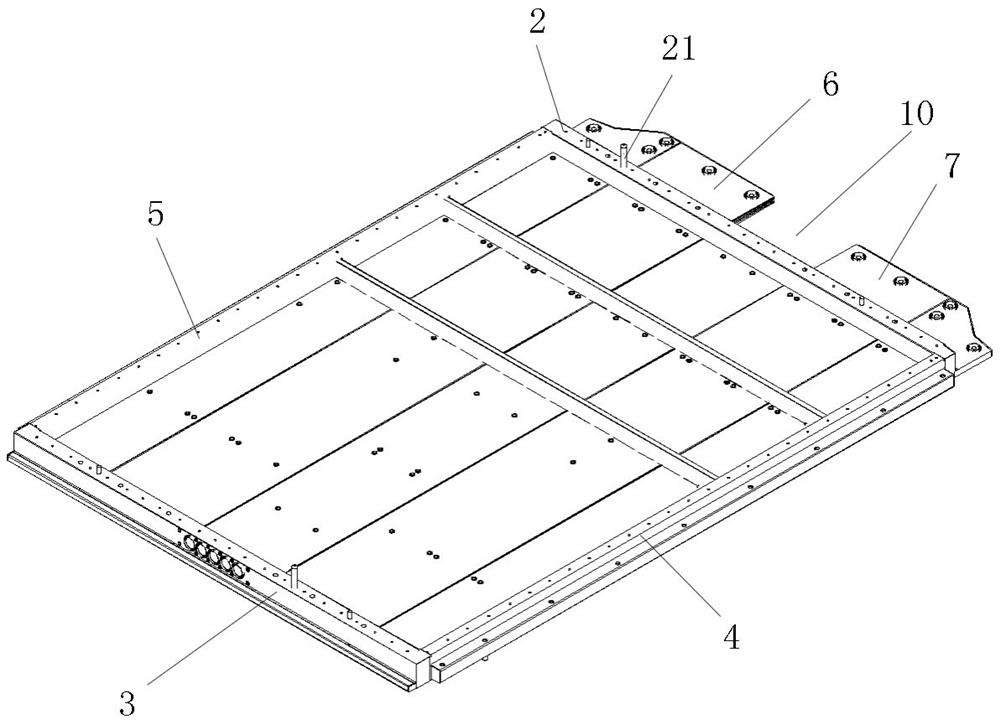

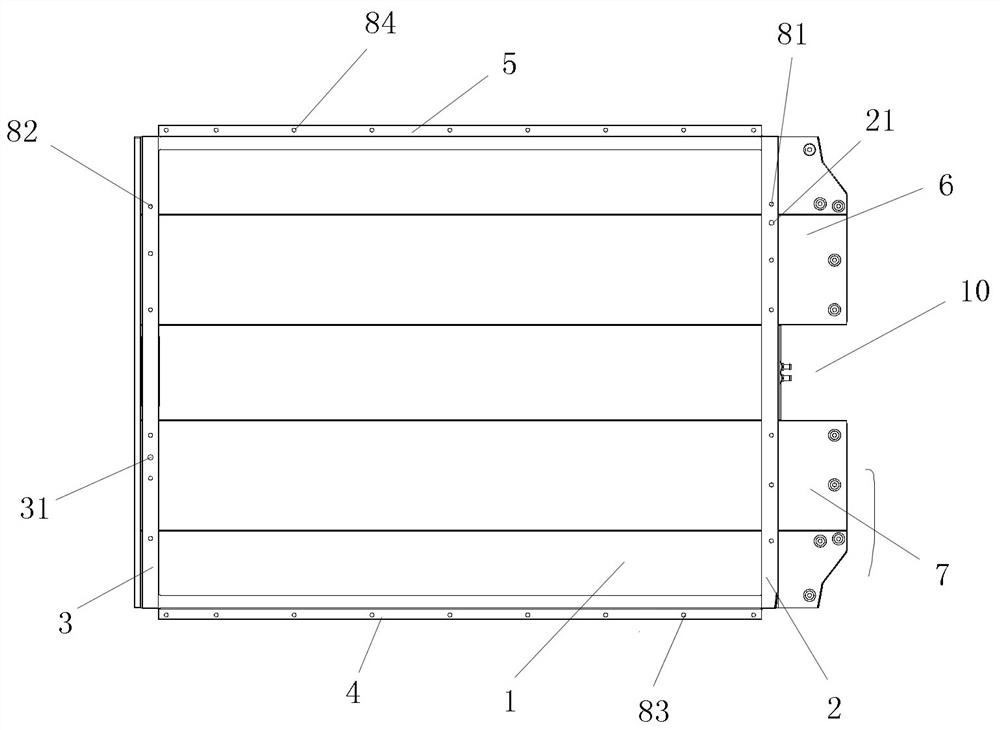

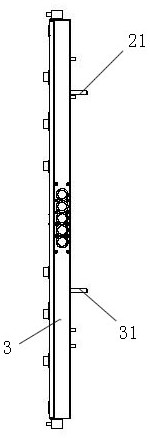

[0015] Such as Figure 1 to Figure 5 The fixed installation structure of a new type of power battery pack shown includes a floor 1, a left longitudinal beam 2, a right longitudinal beam 3, a front beam 4, a rear beam 5, a reinforcing plate upper right sealing plate 6 and a reinforcing plate right lower sealing plate 7. The floor 1 is formed by plugging and assembling five rectangular profiles, and the left side beam 2, the right side beam 3, the front beam 4, and the rear beam 5 are respectively fixed and installed on the left side of the floor 1. , right, front and rear positions, and the left side beam 2 and the right side beam 3 are respectively welded and fixed with the front beam 4 and the rear beam 5, and the left side beam 2 and the right side beam 3 , the front beam 4, and the rear beam 5 are equidistantly provided with several installation holes 81, 82, 83, 84 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com