Filling flow divider

A diverter and filling technology, applied in the directions of packaging, transportation and packaging, packaging item types, etc., can solve problems such as a large number of disassembly and assembly work, difficult dead space volume, etc., to achieve improved weight accuracy, high cycle output, high The effect of partial weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

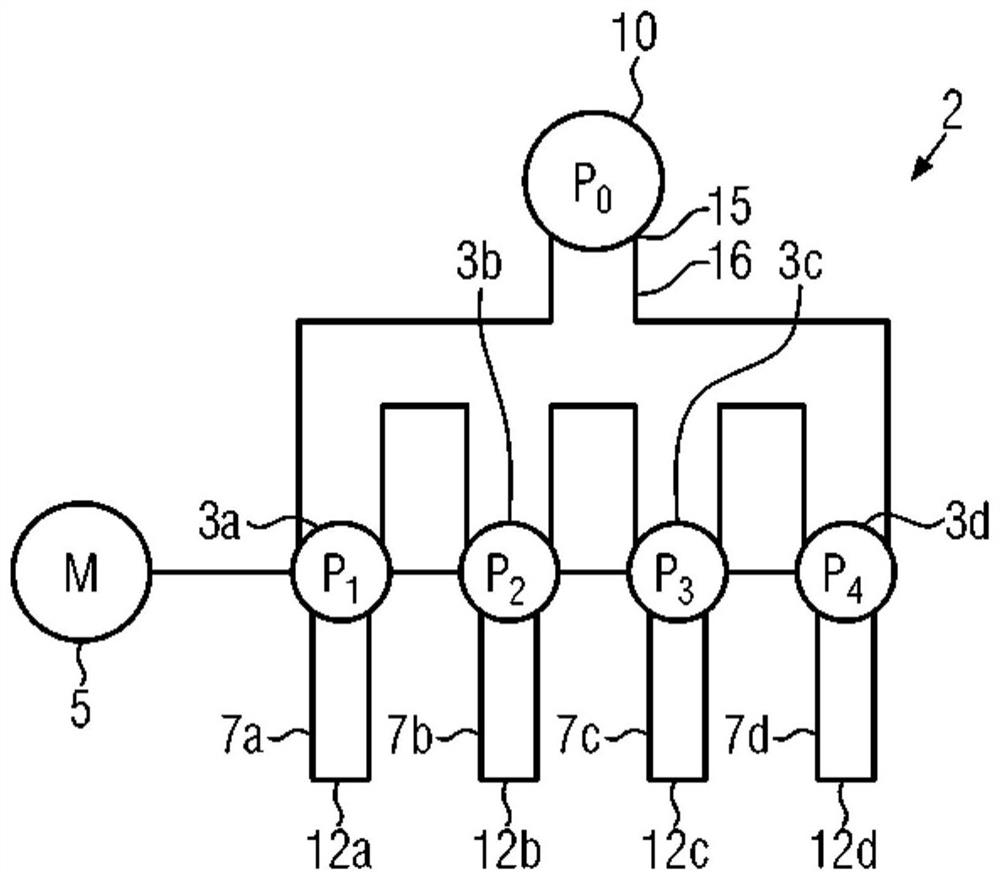

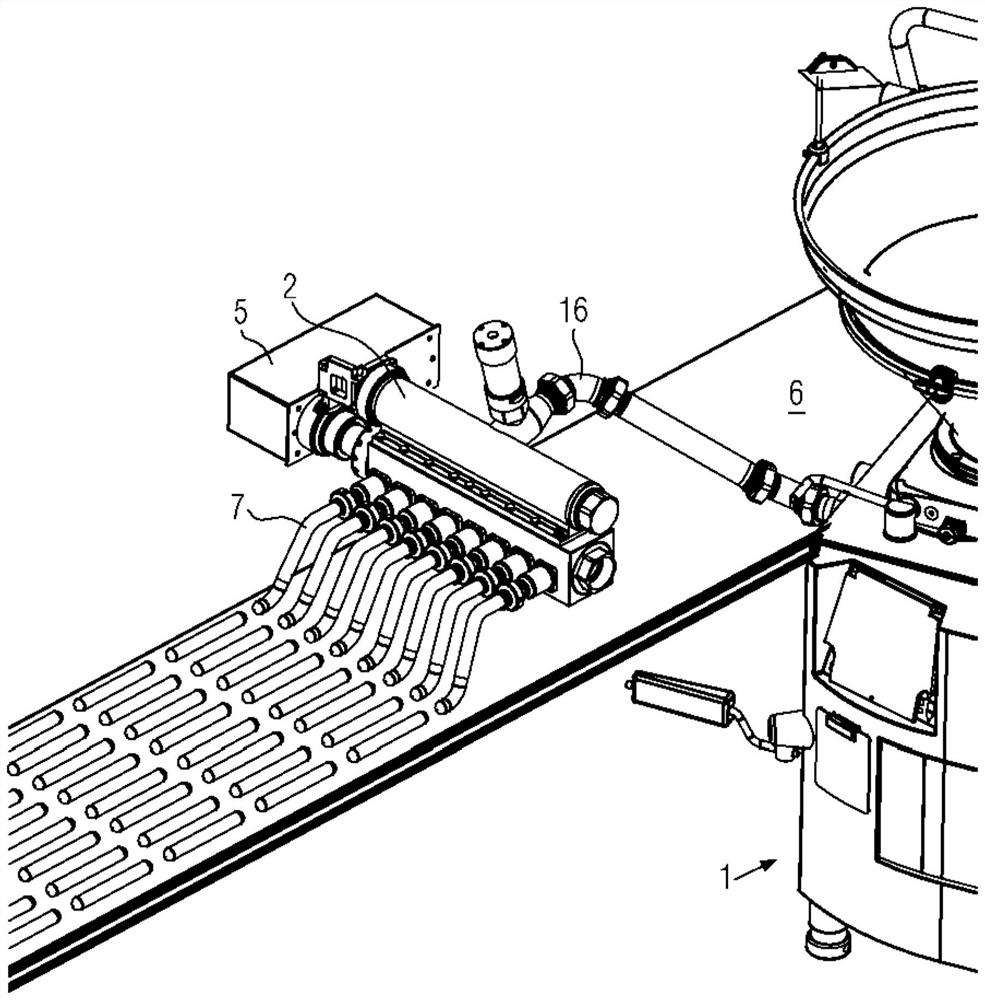

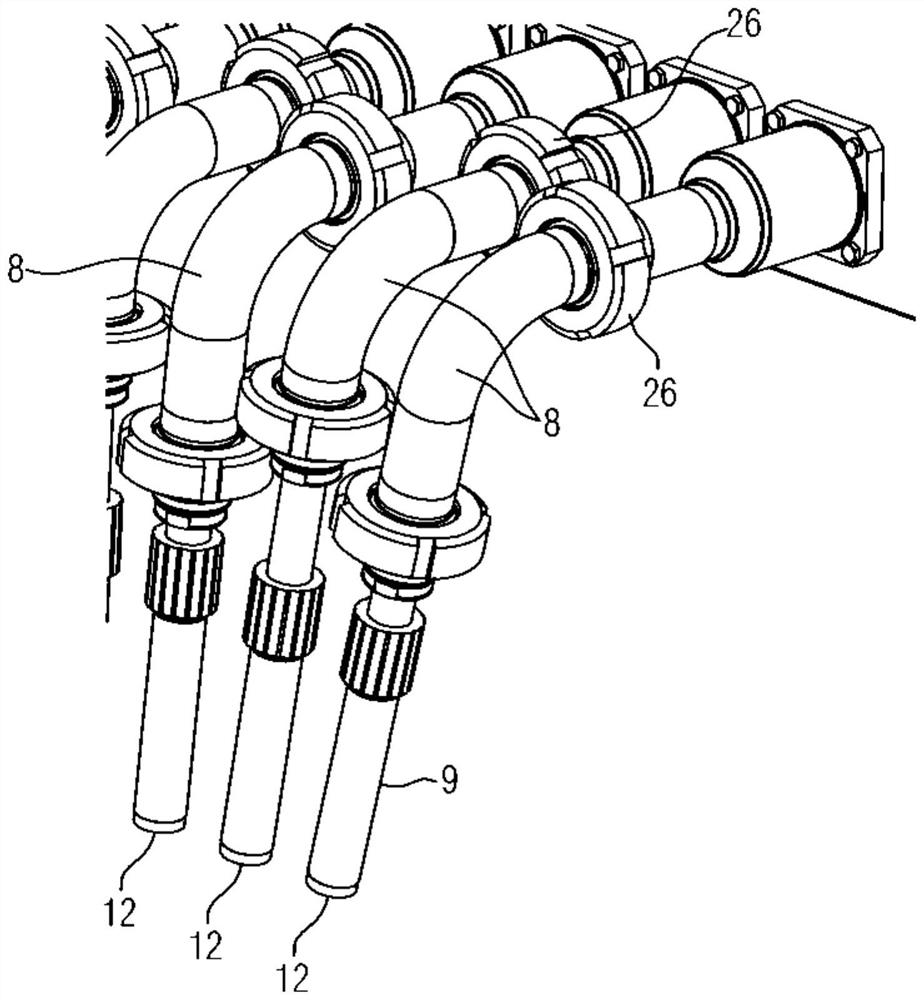

[0036] Figure 6 A device according to the invention is shown. The filling machine 1 comprises a hopper 14 for receiving a pasty material therein. Here, the term pasty mass is used for example for sausage meat, pasta, jam, cream, nut mass and the like. The filling machine 1 is, for example, a vacuum filler. The filling machine comprises a feed mechanism 10 which feeds the pasty material to an outlet 15 (eg outlet pipe). The feeding mechanism may be, for example, a vane pump or a worm pump or the like. For example also arranged downstream of the outlet 15 in the discharge direction at figure 1 and figure 2 A filling splitter of the type shown in 2. The filling splitter divides the material flow (massflow) fed by the feed mechanism 10 into a plurality of (n) material flows (such as in figure 1 The four streams in and for example in figure 2 eight streams in ). To this end, the common line 16 branches into a plurality of lines 7a, 7b, 7c, 7d.

[0037] In order to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com