Die forging high-strength scraper conveyor

A scraper conveyor, high-strength technology, applied in the field of conveyors, can solve the problems of shrinking space, reducing material transmission efficiency, low material transportation efficiency, etc., and achieve the effect of preventing material from spilling and reducing material transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

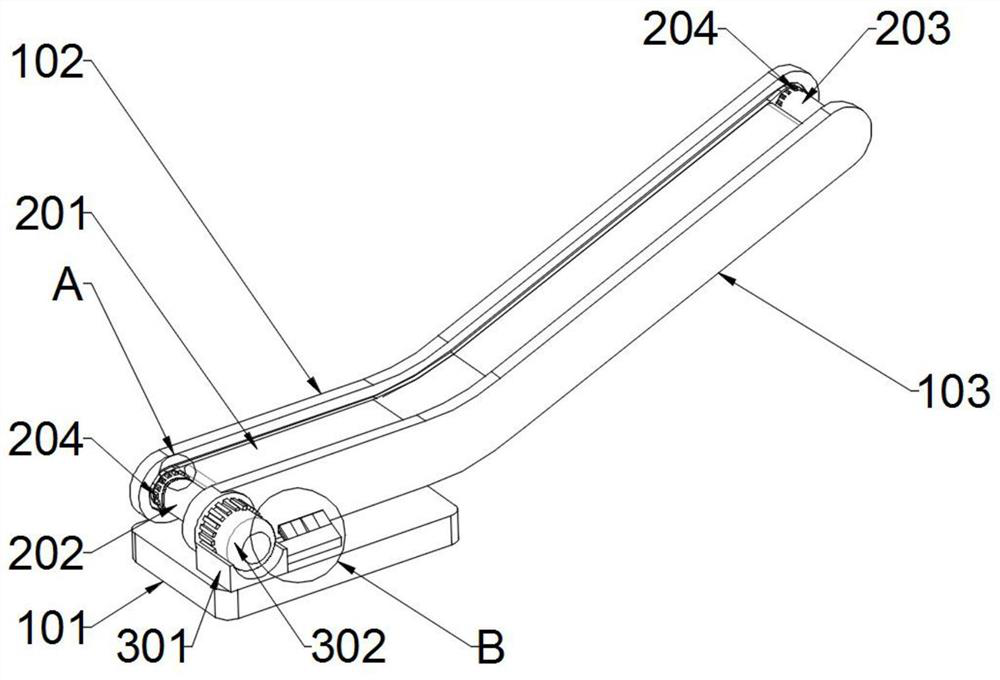

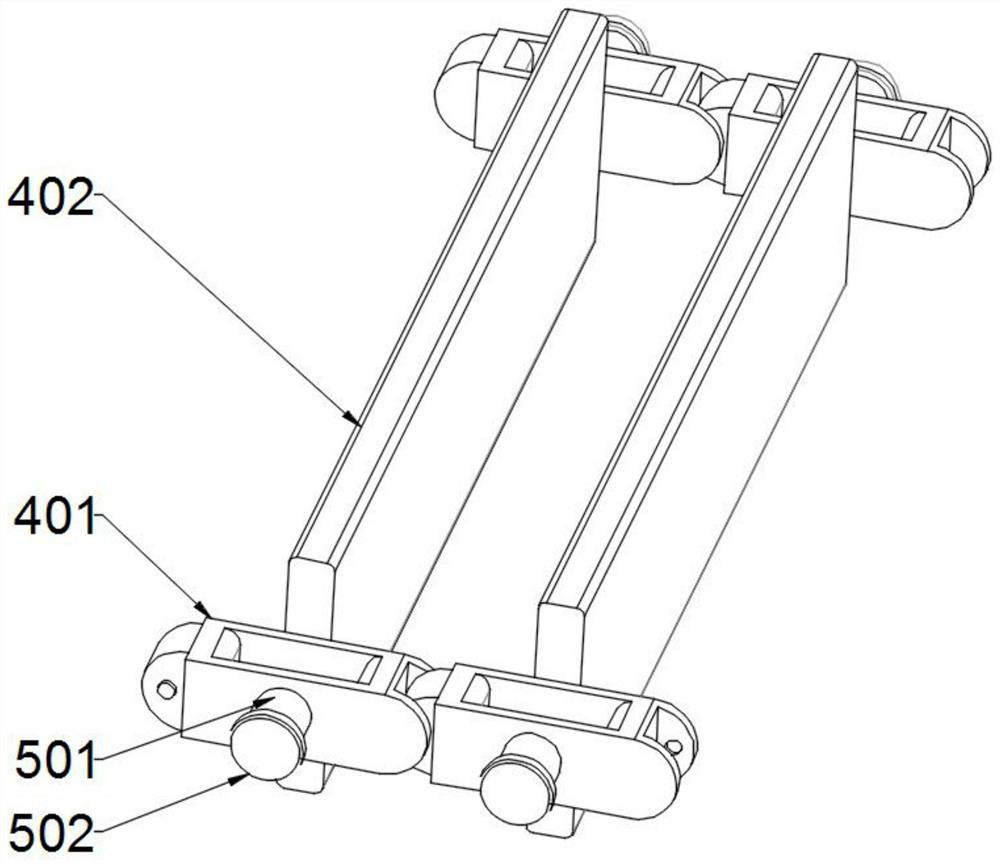

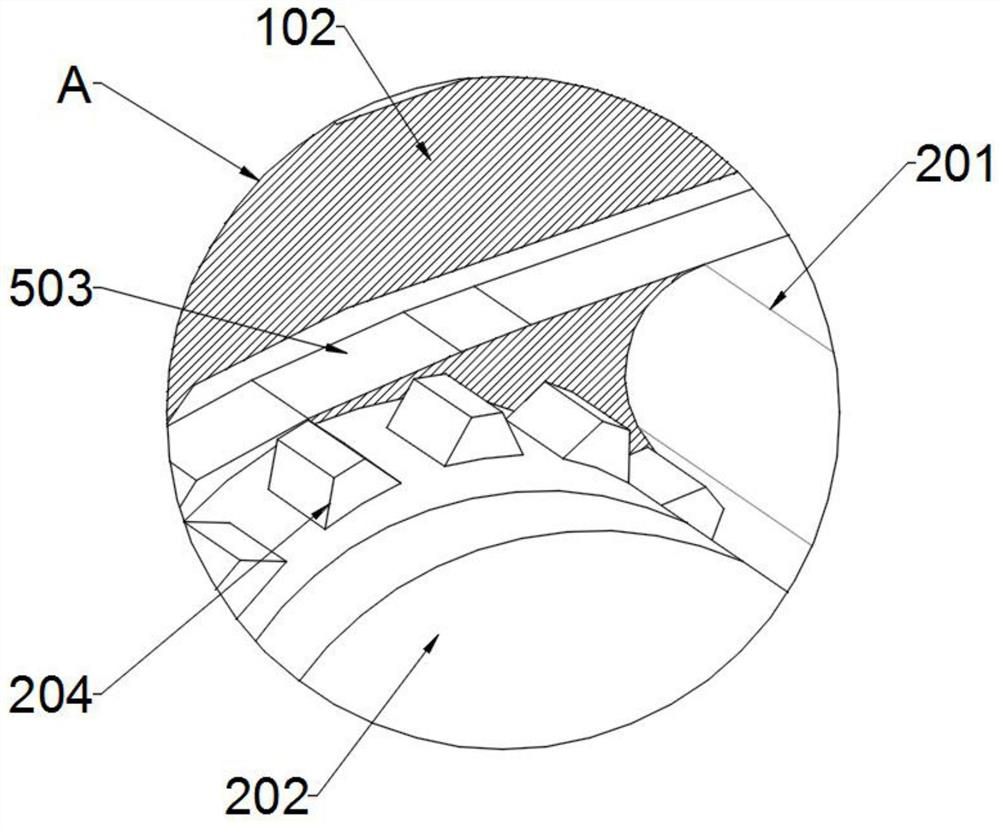

[0023] Example: such as Figure 1-7 As shown, the die-forged high-strength scraper conveyor includes a support assembly, a transmission assembly, a power source assembly, a scraping assembly, a guide assembly, a cleaning assembly, a fixed plate assembly, and a trigger assembly. The support assembly is located on the outermost side of the entire device , which plays the role of supporting other parts of the device. One end of the supporting component is provided with a transmission component, which plays the role of power transmission. One side of the transmission component is provided with a power source component. The power source component is the power source of the device. On the transmission component There is a scraping assembly, which plays the role of pushing the material to move. There is a guide assembly on the side of the scraping assembly, which plays the role of guiding and limiting the scraping assembly. One side of the guide assembly is provided with a cleaning C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com