Thrust bearing, compressor and air conditioner

A thrust bearing and axial technology, which is applied in the field of compressors, can solve the problems of unstable operation of the compressor, the inability of the gas film force to balance with the axial force, etc., to improve energy utilization, improve dynamic pressure performance, and increase bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

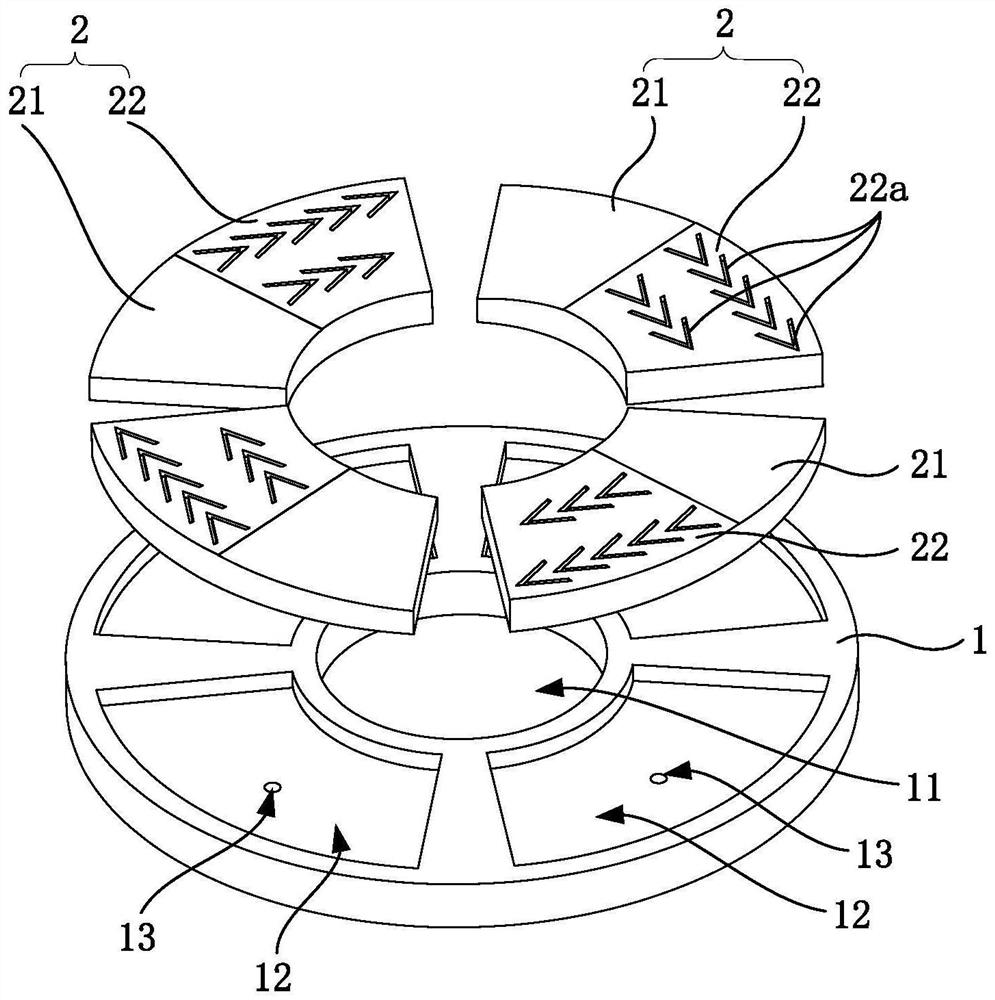

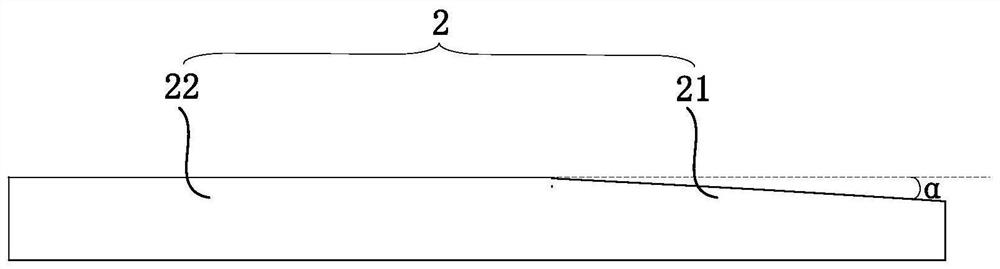

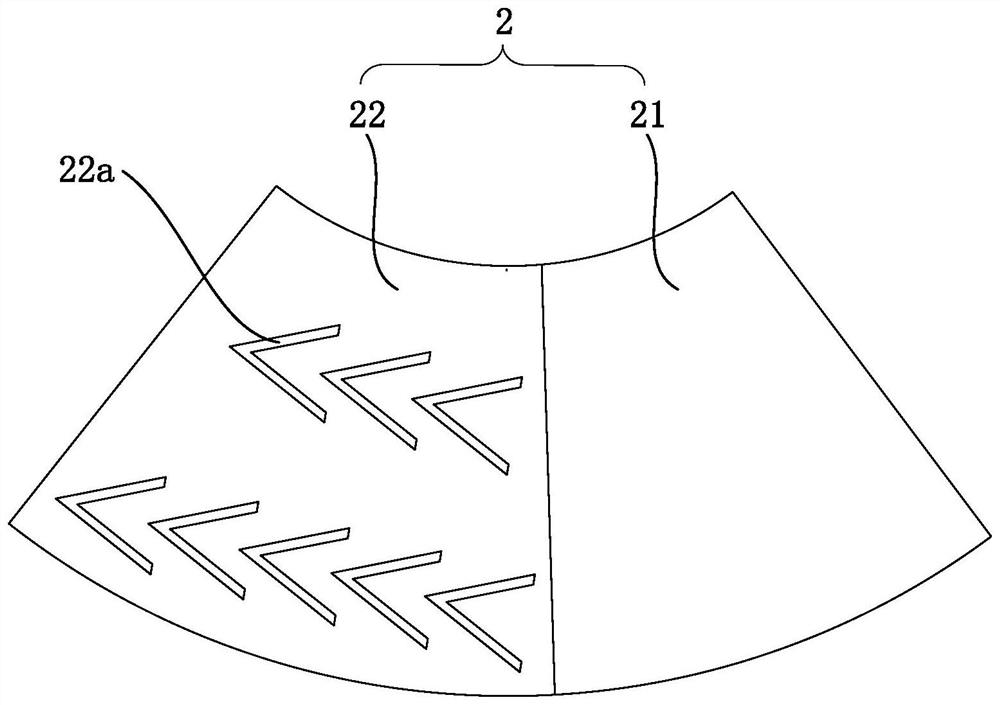

[0028] Combine below Figure 1 ~ Figure 3 The technical solution provided by the present invention is described in more detail.

[0029] see figure 1 , some embodiments of the present invention provide a thrust bearing, including a housing 1 and a restrictor 2 .

[0030] The casing 1 mainly plays the role of fixing the restrictor 2 and providing an air supply channel for the restrictor 2 . The housing 1 has a through hole 11, and the through hole 11 of the housing 1 is provided with an inner concave portion 12 along one axial surface, and the bottom of the inner concave portion 12 is provided with a vent hole through the axial direction of the housing 1 13. The casing 1 is used to provide support, and the casing 1 is disc-shaped. A through hole 11 is provided in the middle of the housing 1, and the through hole 11 is used to pass through the rotating shaft of the compressor. One side surface of the casing 1 is provided with an inner concave portion 12 sunken inward, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com