A tubular crawling robot induced by a three-tube flexible actuator

A crawling robot and actuator technology, applied in the direction of pipes/pipe joints/pipe fittings, pipe components, special pipes, etc., can solve the problems of poor detection effect of flexible robots in the range of motion, and achieve small weight, good flexibility, and flexibility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

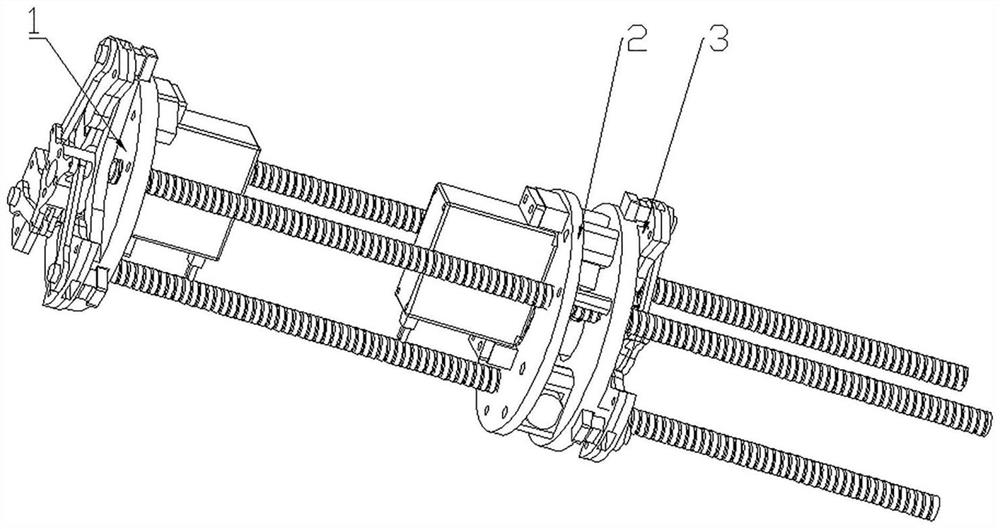

[0024] In this example, if figure 1 As shown, a tubular crawling robot induced by a three-tube flexible actuator includes a top iris mechanism adhesion device 1, a hose gear meshing drive device 2 and a bottom iris mechanism adhesion device 3; the top iris mechanism adhesion device 1 is set on On the top of the robot, the top iris mechanism adhesion device 1 located at the top of the robot is fixedly connected to one end of the three metal bellows 10 in the hose gear engagement drive device 2, and the motor fixed plate 11 in the hose gear engagement drive device 2 passes through The double-way copper column 15 is firmly connected with the bottom iris mechanism adhesion device 3 .

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

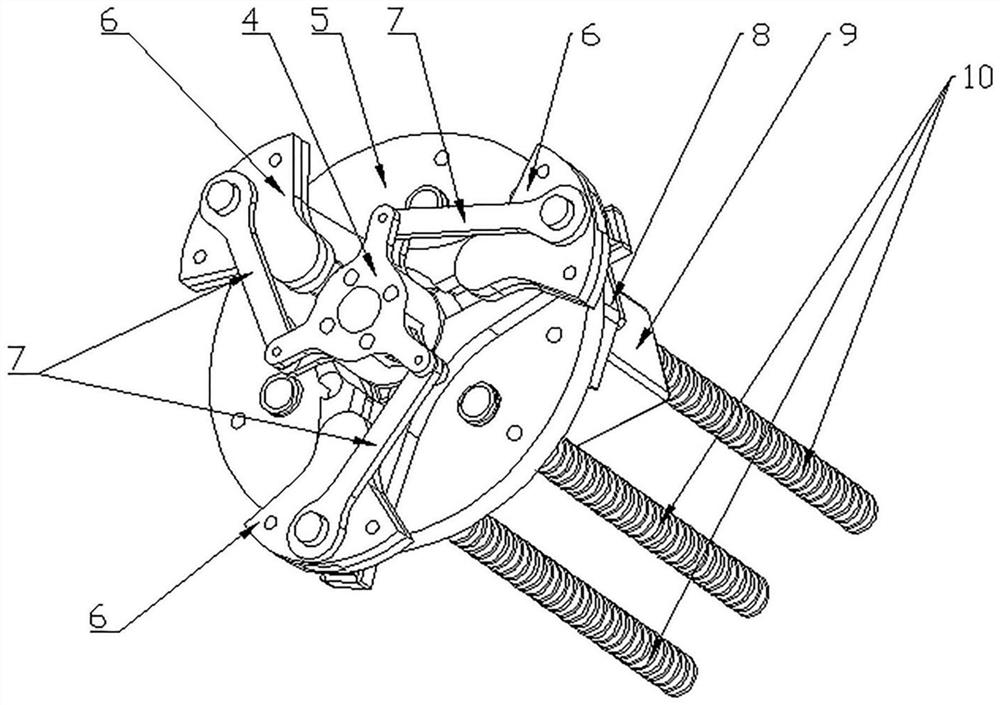

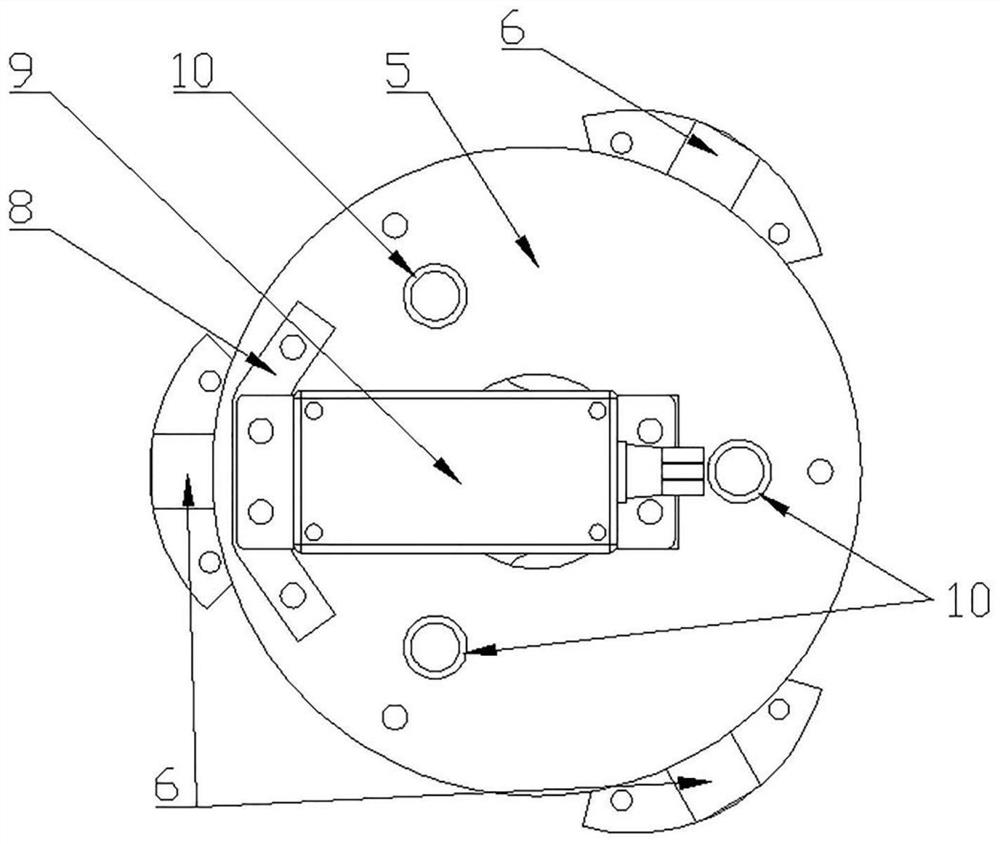

[0027] In this example, if figure 2 and image 3 As shown, the top iris mechanism adhesion device 1 includes a top crank 4, three top connecting rods 7, three top sliders 6, a top chute plate 5, a top steering gear mounting pad 8, and a top steering gear 9 The top crank 4 forms three crank slider mechanisms with three top connecting rods 7, three top sliders 6 and top chute disc 5 respectively, and the top crank 4 is fixedly connected with the top steering gear 9; the top steering gear mounting pad The block 8 is fixedly installed with the top chute plate 5 and the top steering gear 9 by bolts and nuts, and the top slider 6 and the top chute plate 5 form a contact movement pair, and the top slide block 6 can slide on the top chute plate 5. Slide in the lane. The rotation of the top steering gear 9 drives the top crank 4 to rotate, and the rotation of the top crank 4 dri...

Embodiment 3

[0029] This embodiment is basically the same as the above-mentioned embodiment, and the special features are as follows:

[0030] In this example, if Figure 4 and Figure 5 As shown, the hose gear engagement driving device 2 includes three metal bellows 10, three gears 14, three DC motors 12, three motor frames 13, a motor fixing plate 11 and three double-pass copper columns 15; three The metal bellows 10 are evenly distributed on the circumference with a diameter of 50mm at an angle of 120° to each other, and the axial ends of the three metal bellows 10 are fixedly connected with the top chute disc 5 in the top iris mechanism adhesion device 1. The threads on the outer surfaces of the three metal bellows 10 mesh with the three gears 14 respectively to form a rack and pinion mechanism. As the gears 14 rotate, the metal bellows 10 and the gears can move relative to each other. The gear 14 is fixedly connected with the DC motor 12, the DC motor 12 is fixed on one side of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com