A clamping device for DR equipment suitable for complex environments on site

A complex environment, clamping device technology, applied in mechanical equipment, material analysis using radiation, machine/support, etc., can solve the problems of difficult installation and fixation, complex structure, etc., to improve detection efficiency, shorten detection time, save money The effect of detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

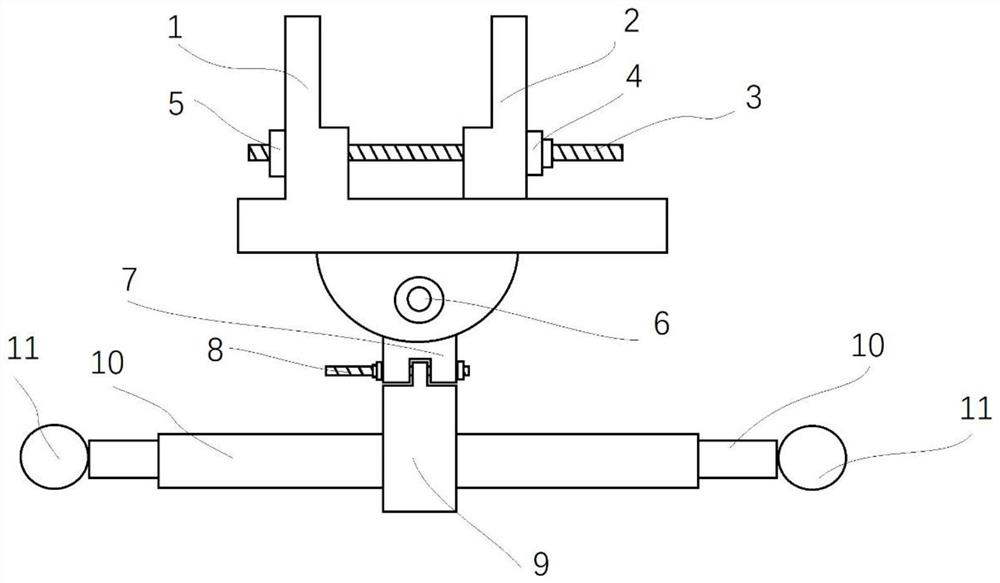

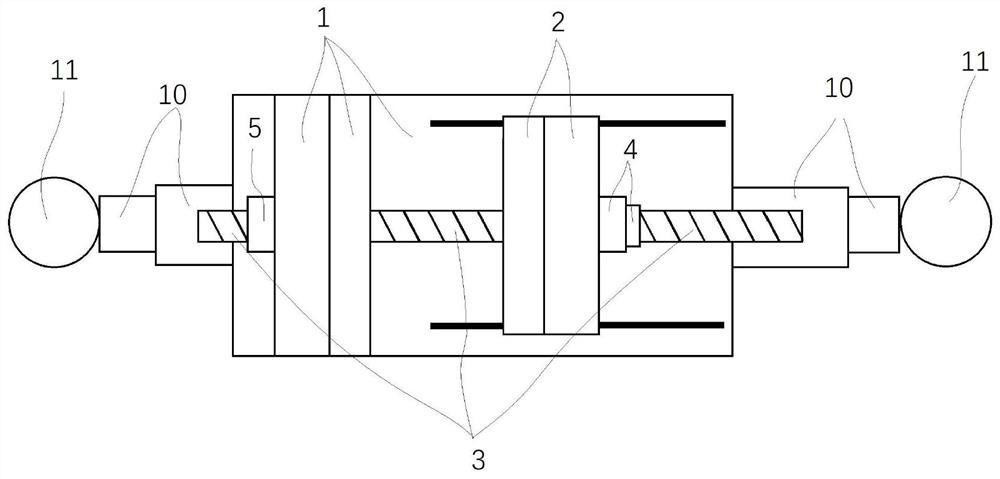

[0028] A DR equipment clamping device suitable for complex on-site environment includes a receiving screen fixture, a DR ray machine fixture and a universal bracket, and the DR ray machine fixture is installed on two universal brackets arranged symmetrically at intervals.

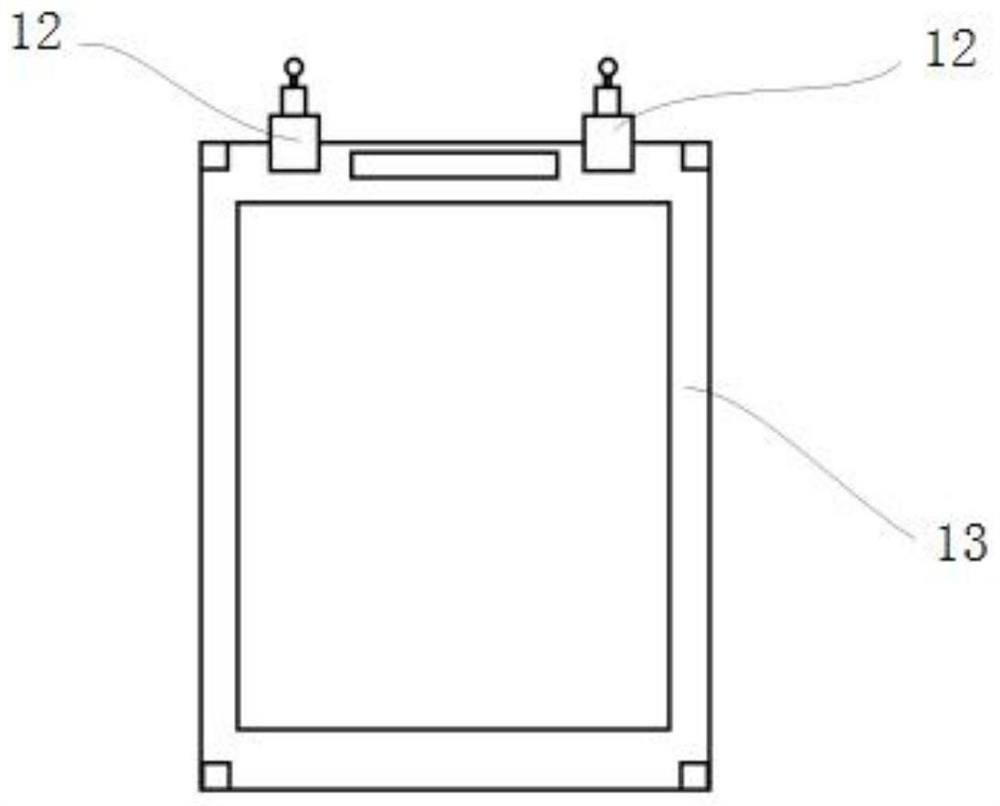

[0029] The receiving screen fixture 12 includes a fixture platform (1), a connecting head (7), a telescopic rod insertion head (9), a telescopic rod (10), and a telescopic rod insertion head ( 9), put the telescopic rod (10) on the telescopic rod insertion head (9). The clamp platform (1) provides a clamping function, which can clamp the receiving screen.

[0030] The fixture platform (1) is composed of a fixed end chuck, a platform, and a hemispherical device with bolt holes. A fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com