Thickness detection mechanism utilizing Hall sensing

A thickness detection and Hall sensing technology, applied in the field of thickness detection, can solve the problems of detection thickness error, influence of thickness detection, inconvenient installation and disassembly of detection sensors, and achieve the effect of convenient disassembly and assembly, convenient adjustment, and improved detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

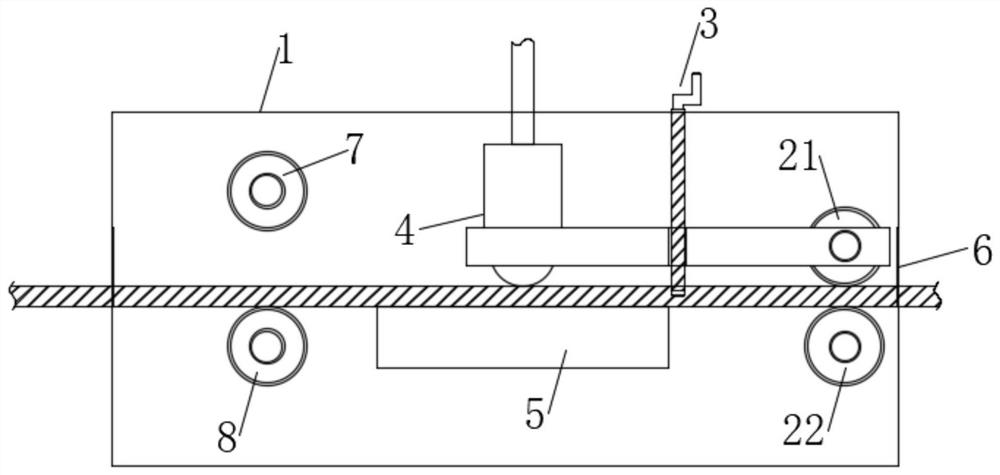

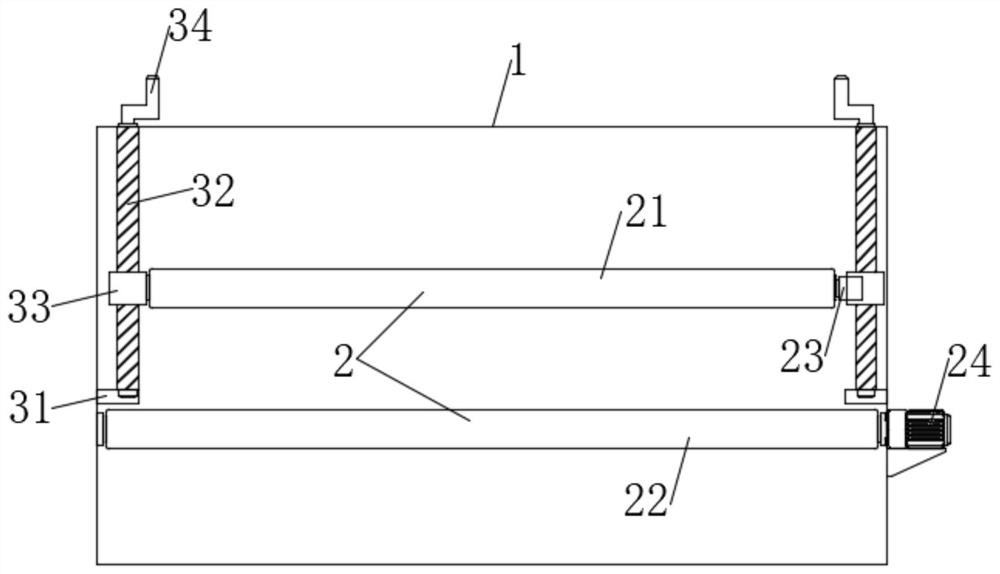

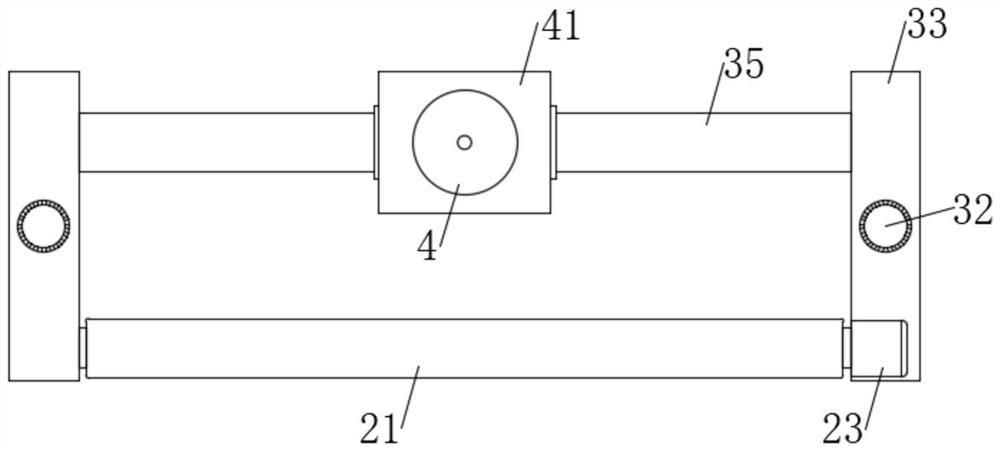

[0025] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a thickness detection mechanism using Hall sensing, including a detection housing 1, a feed roller set 2 and an adjustment mechanism 3, and the opposite sides of the detection housing 1 are provided with There is a detection port 6, and the two detection ports 6 are set at the same height, and the detection housing 1 on one side of the detection port 6 is provided with a feed roller group 2 inside, and the interior of the detection housing 1 is far away from the feed roller group 2 A discharge roller set is provided on one side of the feed roller set, and a Hall sensor 4 is provided inside the detection housing 1 between the feed roller set 2 and the discharge roller set, and a Hall sensor 4 is provided on the Hall sensor 4 and the feed roller set 2. There is an adjustment mechanism 3, a magnetic element 5 is fixedly installed inside the detection housing 1 below the Hall se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com