Ship lock dynamic water valve closing process debugging method capable of shortening water filling time

A technology of water filling time and debugging method, which is applied in the direction of ship locks, ship lifting devices, special data processing applications, etc., and can solve the problem of damage to the mechanical and electrical equipment of the miter door opening and closing mechanism components, high water level inertia in the lock chamber, and damage to the ship. Safety and other issues, to improve the efficiency of ship lock passage, reduce the number of groups and time, and facilitate the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

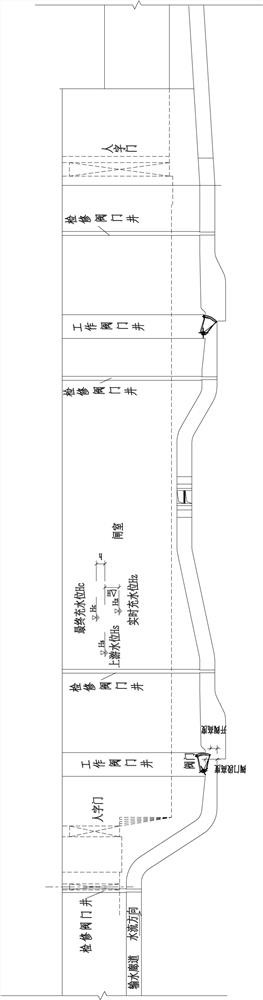

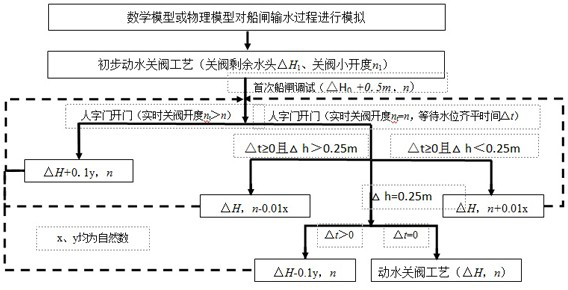

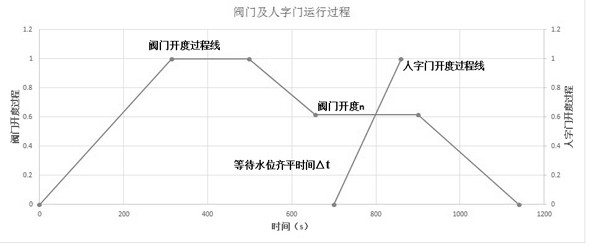

[0024] Such as Figure 1~3 As shown, a process debugging method for shiplock dynamic water closing valves that shortens the water filling time includes the following steps: Step 1, the water level in the lock chamber is equal to the downstream water level, the downstream miter gate is closed, and the discharge valve is closed.

[0025] Step 2: Open the water filling valve to fill the gate chamber with water until the water filling valve is fully open, that is, the opening value is 1.

[0026] Step 3. Synchronously calculate the difference between the water level in the lock room and the upstream water level of the ship lock during the water filling process, that is, the remaining water head △H value. When the remaining water head △H=△H m , start to close the water filling valve, △H m For the mth debugging of the remaining water head of the dynamic water closing valve, when the water filling valve is closed to the opening degree n=n a When, stop valve closing action, n a To ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com