Sealing ring assembling mechanism

An assembly mechanism and sealing ring technology, applied in the field of parts assembly, can solve the problems of clamping, conveying, long assembly time and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

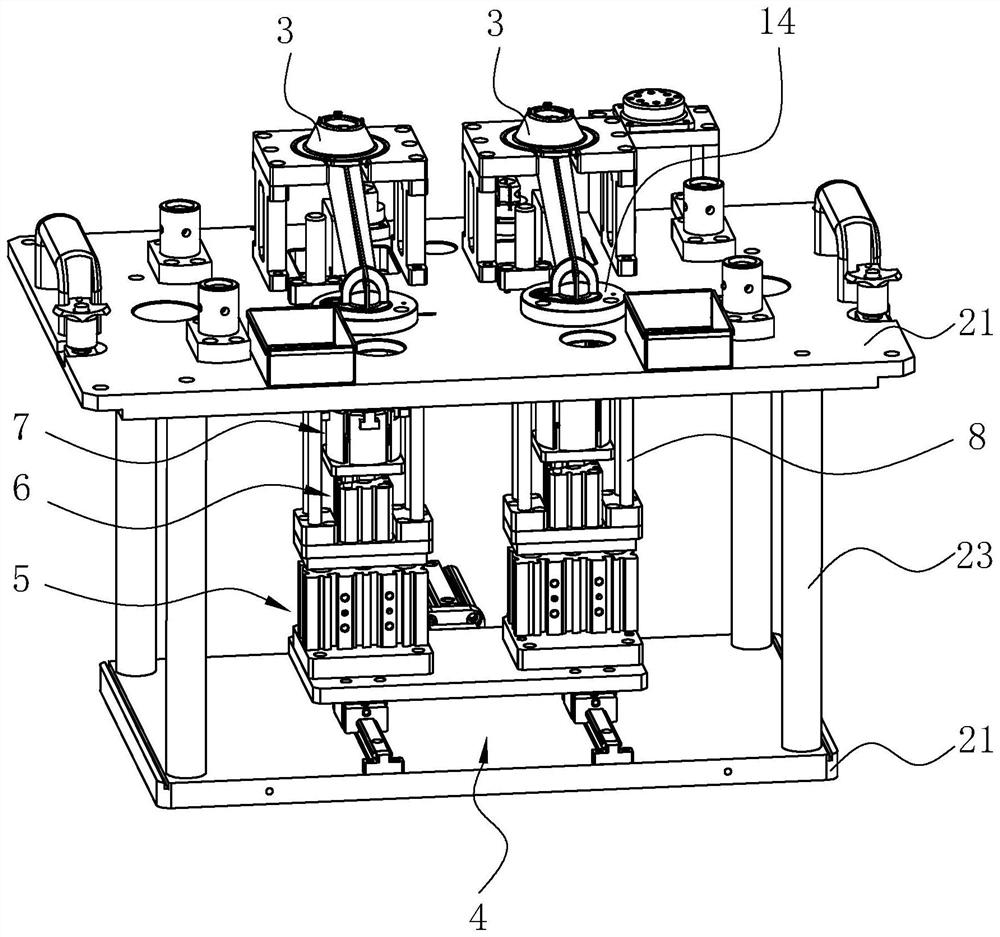

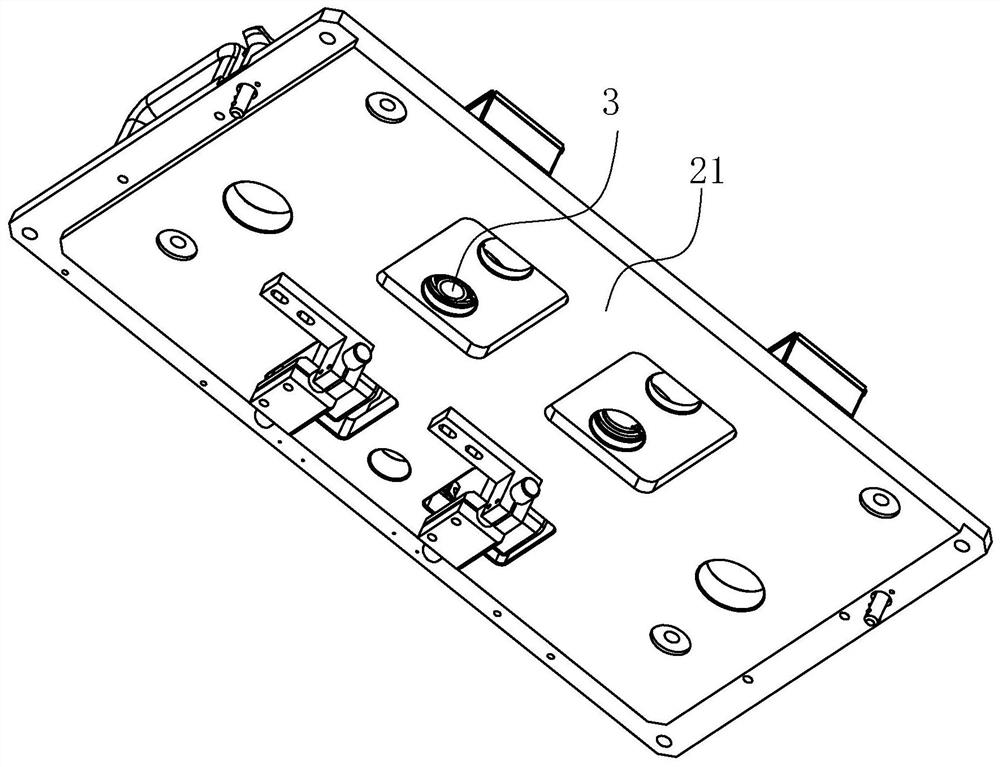

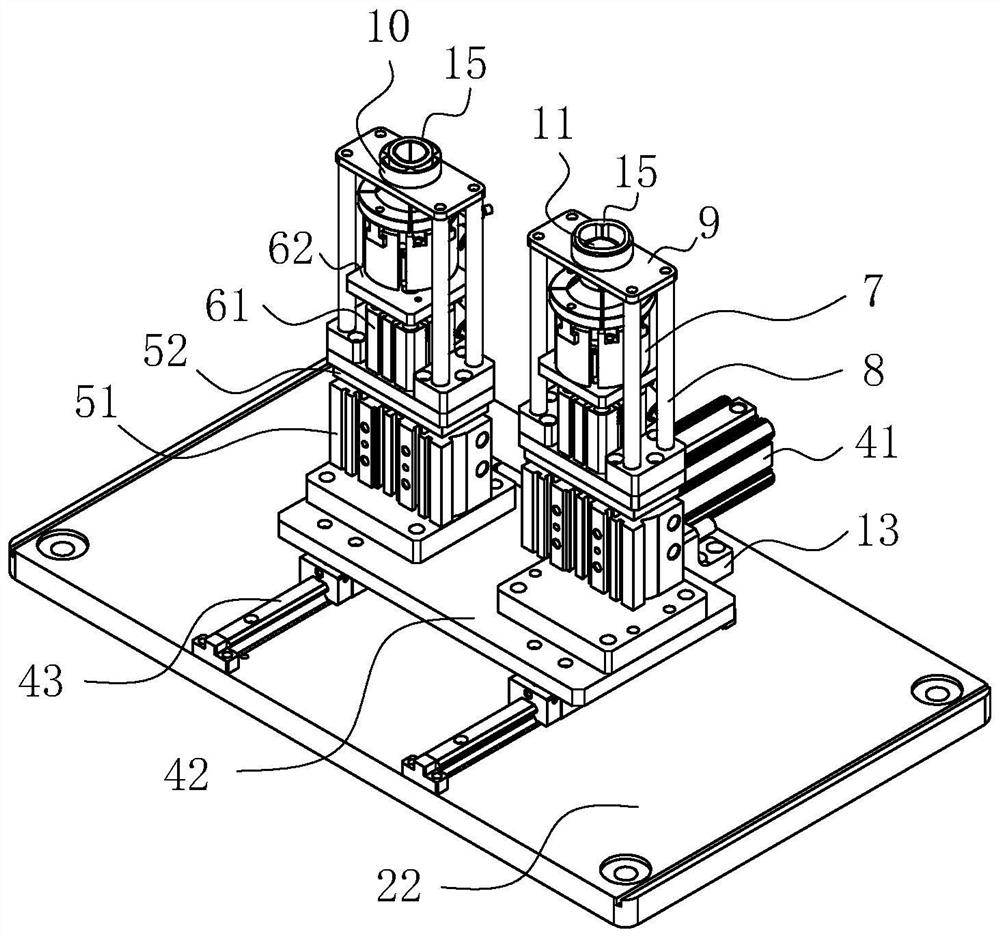

[0049] refer to figure 1 and figure 2 , is a sealing ring assembly mechanism disclosed in the present invention, which includes a frame 1 that is in the shape of a square prism as a whole, and the frame 1 includes a first base plate 21 and a second base plate 22 that are in the shape of a cuboid as a whole. The first substrate 21 and the second substrate 22 are parallel to each other, and a plurality of support columns 23 perpendicular to the first substrate 21 are installed between the first substrate 21 and the second substrate 22, and the support columns 23 are located on four sides of the first substrate 21. corner. A product 3 is placed on the first base plate 21 , and the product 3 needs to be installed with a sealing member 15 to be assembled, and the sealing member 15 is a sealing ring made of rubber. Located between the first substrate 21 and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap