Rolled tissue rowed bagging equipment

A technology for packing bags and paper towels in a row, which is applied in the field of bagging equipment for roll paper towels in rows, and can solve the problems of slow bagging speed of roll paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

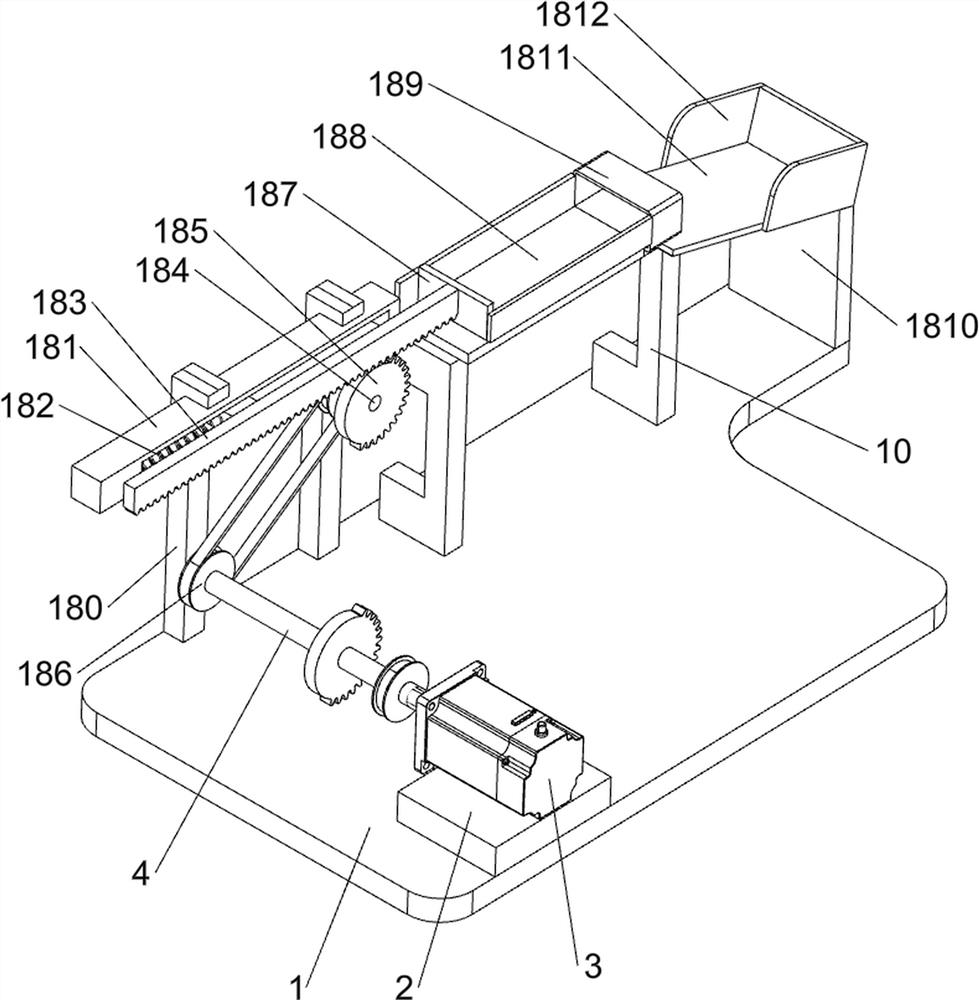

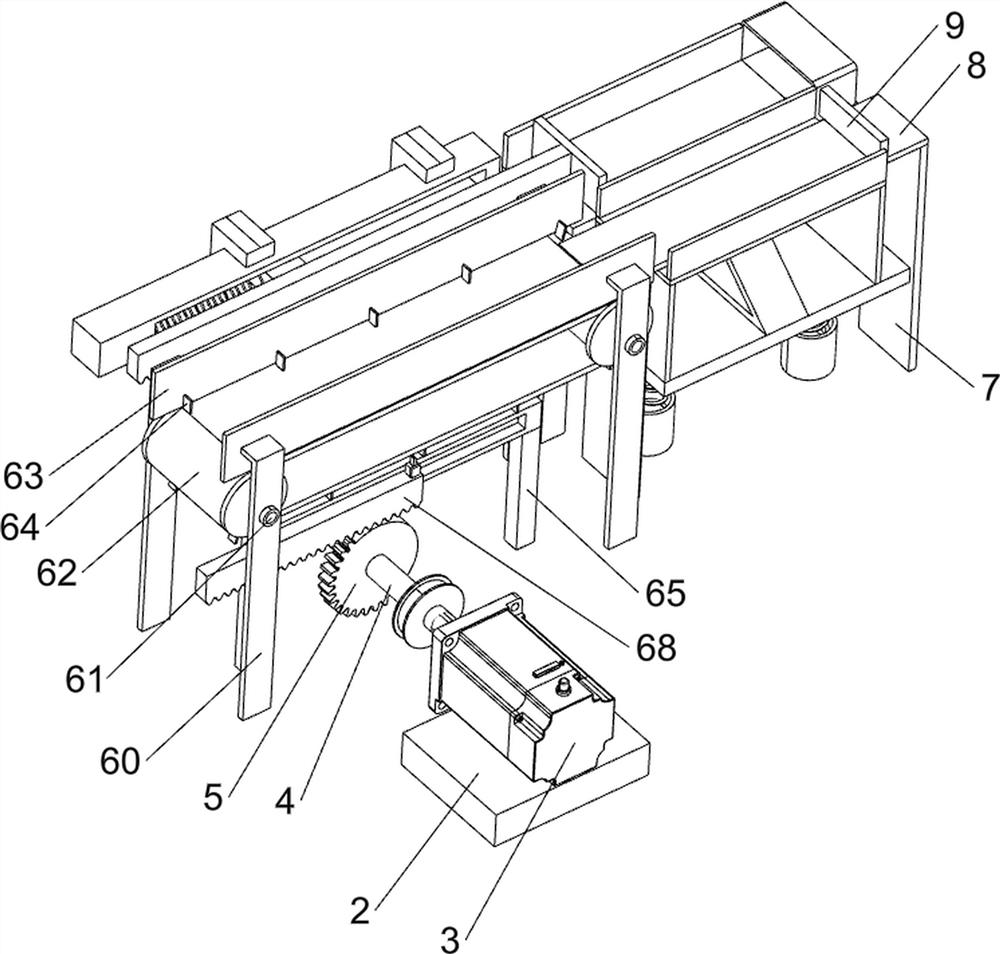

[0023] A roll-shaped paper towel bagging equipment in rows, such as Figure 1-3 and Figure 5-6 As shown, it includes a bottom plate 1, a base 2, a servo motor 3, a first rotating shaft 4, a first missing gear 5, a feeding mechanism 6, a first support plate 7, a first connecting plate 8, a baffle plate 9, and a second slide rail 10. The second slider 11, the lifting plate 12, the mounting seat 13, the second spring 14, the second support plate 15, the second protective plate 16, the pushing mechanism 17 and the bagging mechanism 18, the upper left front side of the bottom plate 1 is provided with a base 2 , the upper part of the base 2 is provided with a servo motor 3, the output shaft of the servo motor 3 is connected with a first rotating shaft 4, the first rotating shaft 4 is provided with a first missing gear 5, and the upper left rear of the base plate 1 is provided with a feeding mechanism 6, the base plate 1 The right side of the upper part is symmetrically provided wi...

Embodiment 2

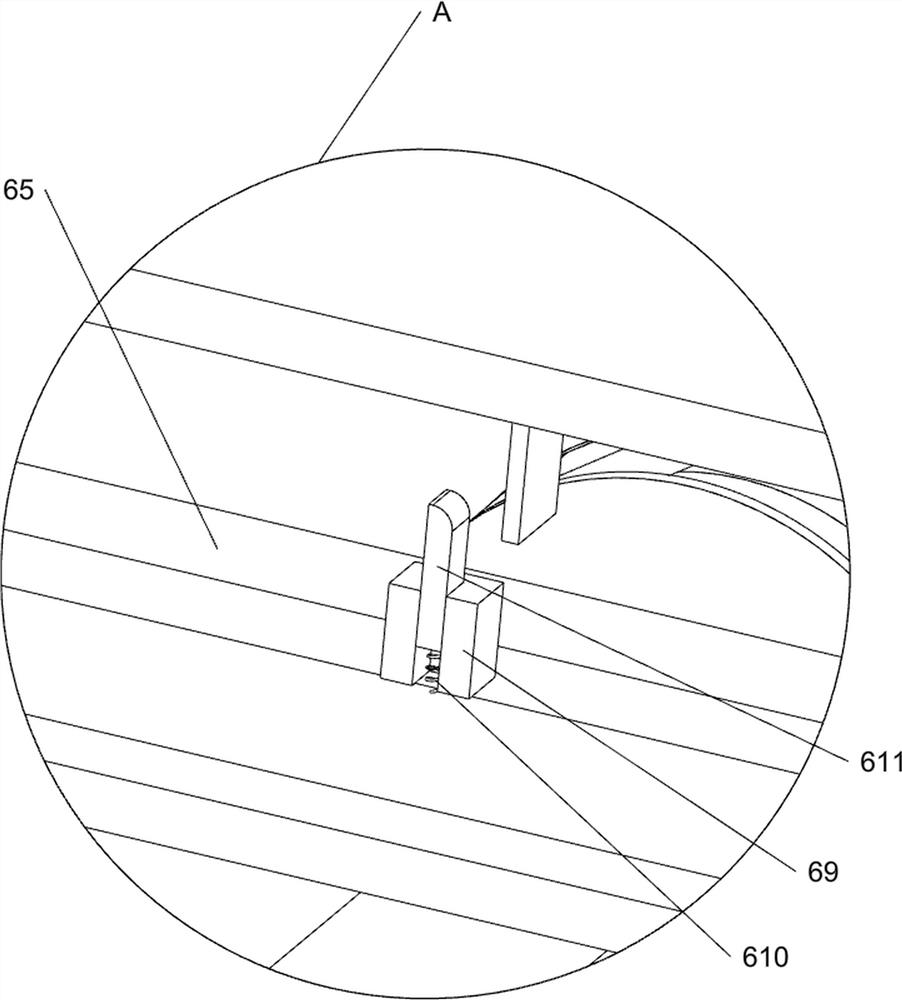

[0026] On the basis of Example 1, such as Figure 2-4 As shown, the feeding mechanism 6 includes a first bearing seat 60, a second rotating shaft 61, a conveyor belt 62, a first protective plate 63, a first push block 64, a first bracket 65, a first spring 66, a first slider 67, The first tooth bar 68, the supporting block 69, the return force spring 610 and the elevating rod 611, four first bearing seats 60 are evenly arranged on the left side of the bottom plate 1 top, and the first bearing seats 60 on the front and rear sides are all rotatably provided with The second rotating shaft 61, a conveyor belt 62 is connected between the second rotating shaft 61 on both sides, and a plurality of first push blocks 64 are arranged symmetrically front and back on the conveyor belt 62, and a first push block 64 is arranged between the first bearing blocks 60 on the left and right sides. A protective plate 63, the first protective plate 63 is positioned at the top of the conveyor belt 6...

Embodiment 3

[0033] On the basis of Example 2, such as image 3 and Figure 5 As shown, push rod 19, roller 20 and wedge block 21 are also included, push rod 172 rear portion is provided with push rod 19, push rod 19 rear end is provided with roller 20, and lifting plate 12 top is provided with wedge block 21, wedge block 21 cooperates with roller 20.

[0034] The guide block 171 moves backward to drive the push rod 19 and the roller 20 to move backward, so that the roller 20 moves along the wedge block 21, and presses the wedge block 21 downward, so that the lifting plate 12 moves downward, so that there is no need to manually move up and down Press the lifting plate 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com