Manual winter peach bagging machine

A bagging machine and winter peach technology, applied in plant protection cover, botanical equipment and methods, gardening and other directions, can solve the problems of delayed winter peach management, unfavorable winter peach planting, high labor intensity, and shorten the bagging time. , the structure is simple, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

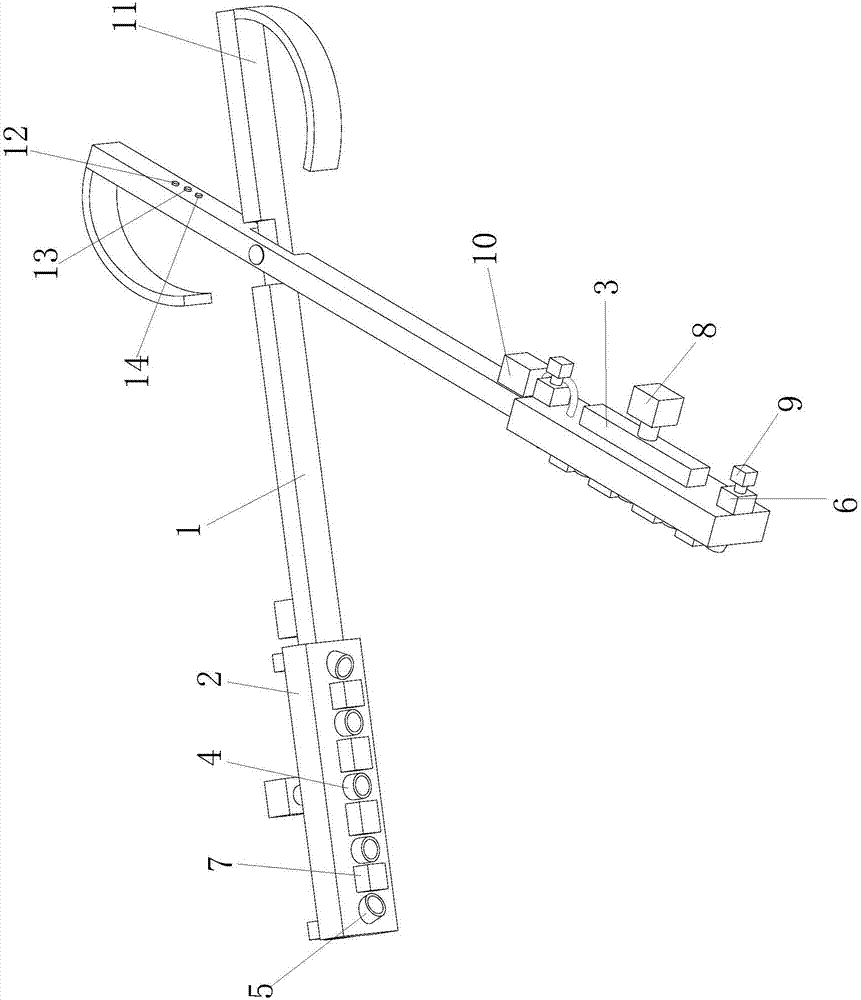

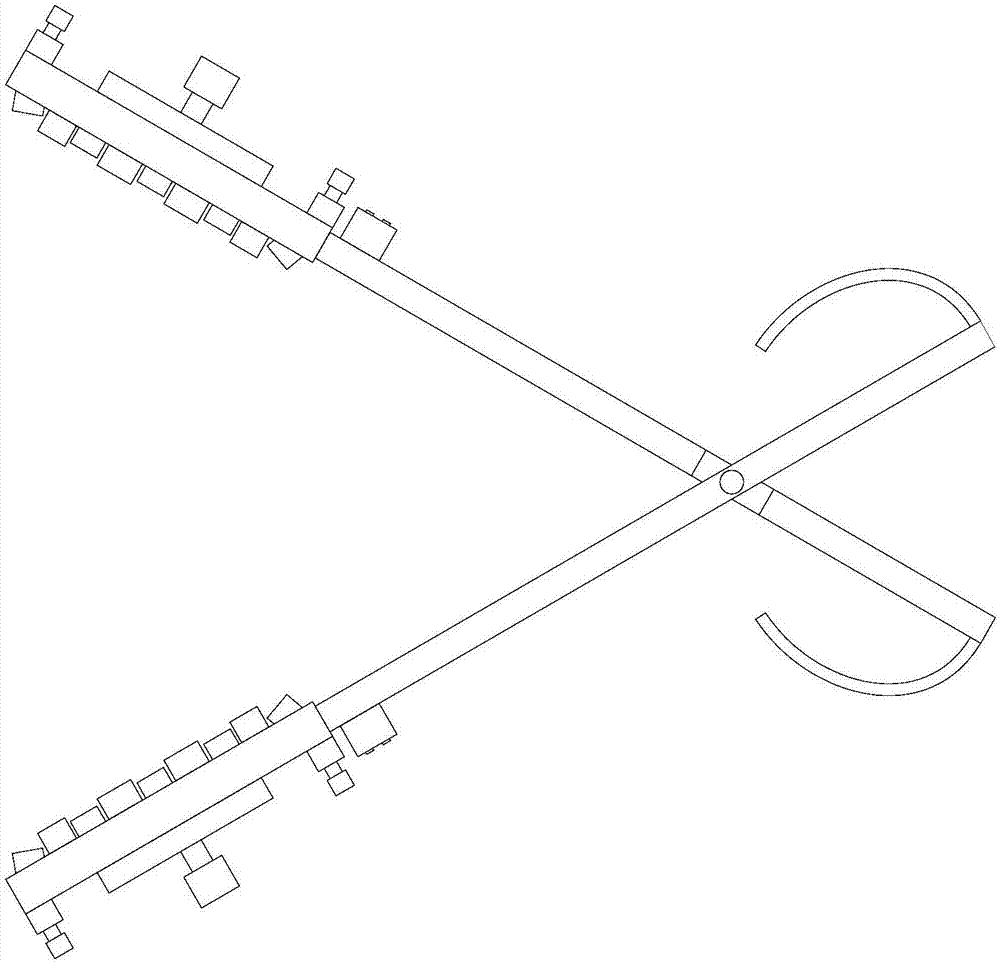

[0016] Such as Figure 1 to Figure 2 As shown, a manual winter peach bagging machine includes two long plates 1 crossed in the middle and hinged together, and the two long plates 1 are symmetrically connected with a packaging mechanism; The bearing plate 2 at the free end, the suction chamber 3 connected to the outer surface of the bearing plate 2, the No. 1 air pipe 4 arranged in a row on the inner surface of the bearing plate 2 and communicated with the suction chamber 3, arranged on the left and right sides of the bearing plate 2 The No. 2 trachea 5 distributed obliquely near the center of the carrier plate 2 on both sides, and the air blowing chamber 6 fixed on the carrier plate 2 and connected to the No. 2 trachea 5 , fixed on the carrier plate 2 , are arranged on the same end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com