Integral self-lifting device for upper equipment of tower crane

A tower crane, self-lifting technology, applied in the direction of cranes, etc., can solve the problem that the boom and the balance arm cannot be freely lifted and lowered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

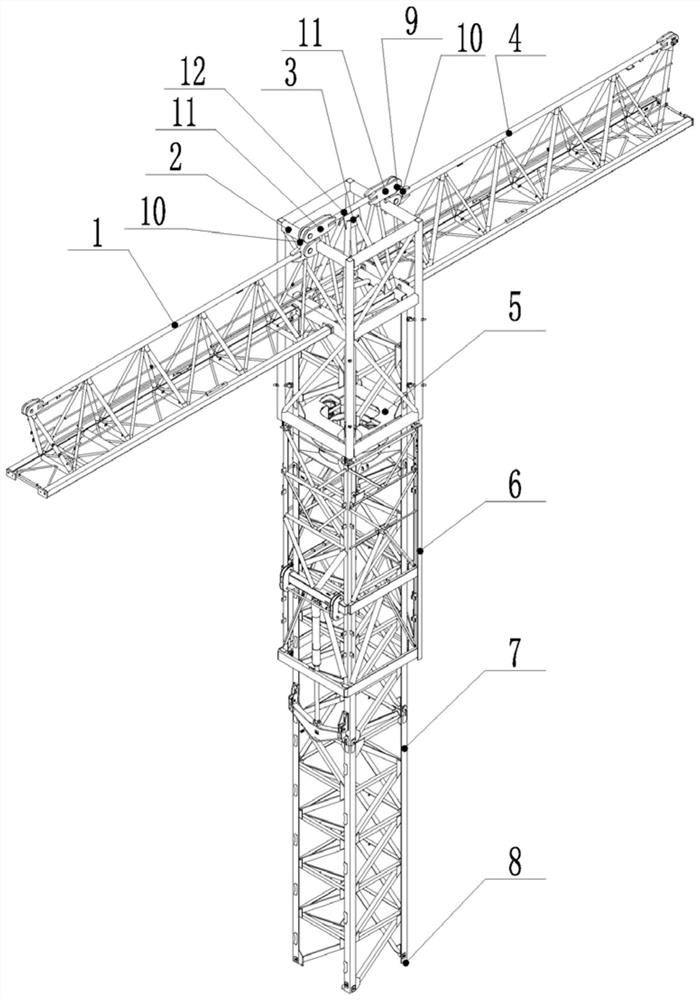

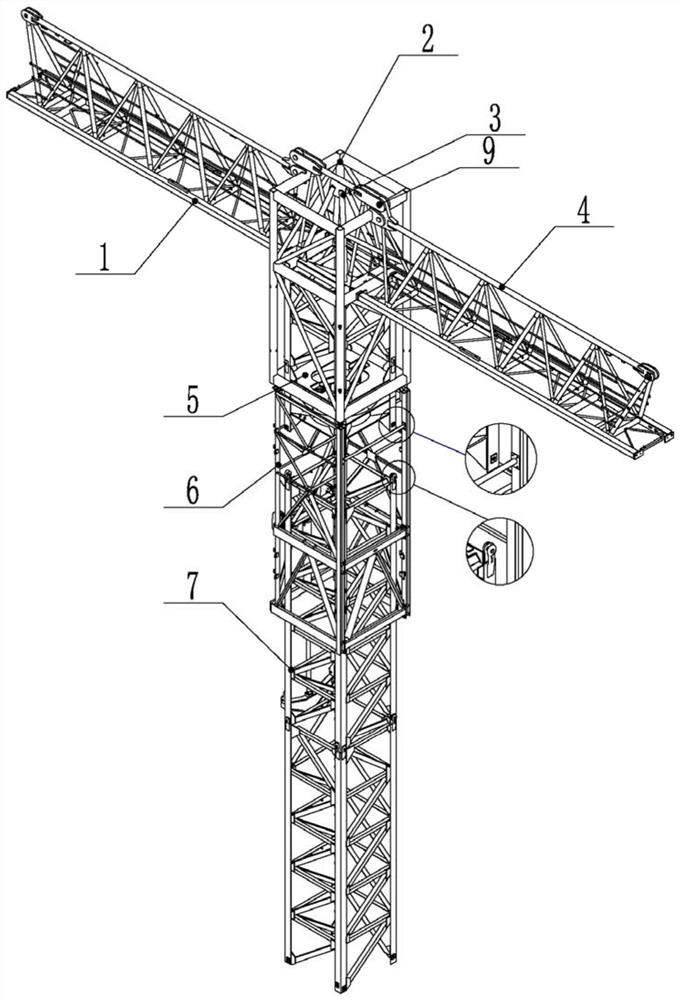

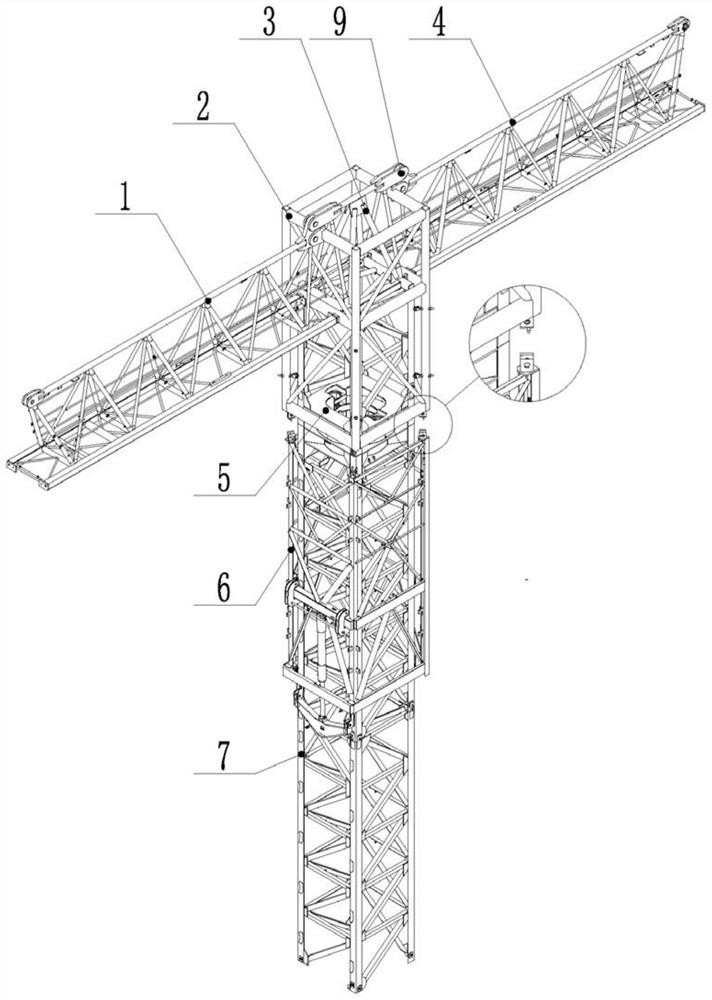

[0011] Such as figure 1 As shown, the present invention includes a tower body 7 fixed on the ground by a fixed foot 8 and composed of three standard joints. The outside of the tower body 7 is equipped with a jacking sleeve 6 controlled by the jacking device of the tower crane itself. The top is connected with the bottom of the rotary assembly 5 by pin shafts. The upper part of the slewing assembly 5 is connected with the tower head 3 through a pin shaft. On the outer side of the tower head 3, there is an outsourcing tower head 2 connected to it through a pin shaft 9. The two sides of the outsourcing tower head 2 are respectively connected to the balance arm 1 and the jib assembly 4 through a pin shaft, and the lower end is placed on the upper part of the jacking sleeve 6. .

[0012] Such as figure 2 As shown, disassemble the pin shaft connecting the tower head 3 and the upper part of the slewing assembly; start the jacking system to perform the jacking operation normally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com