Novel mud conveying pipeline for cutter suction ship and construction method thereof

A construction method and the technology of the cutter suction vessel, which are applied in the directions of earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve problems such as affecting productivity, burst pipes, pipeline damage, etc., and achieve cost savings , avoid pipe burst, reduce the effect of pipe wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

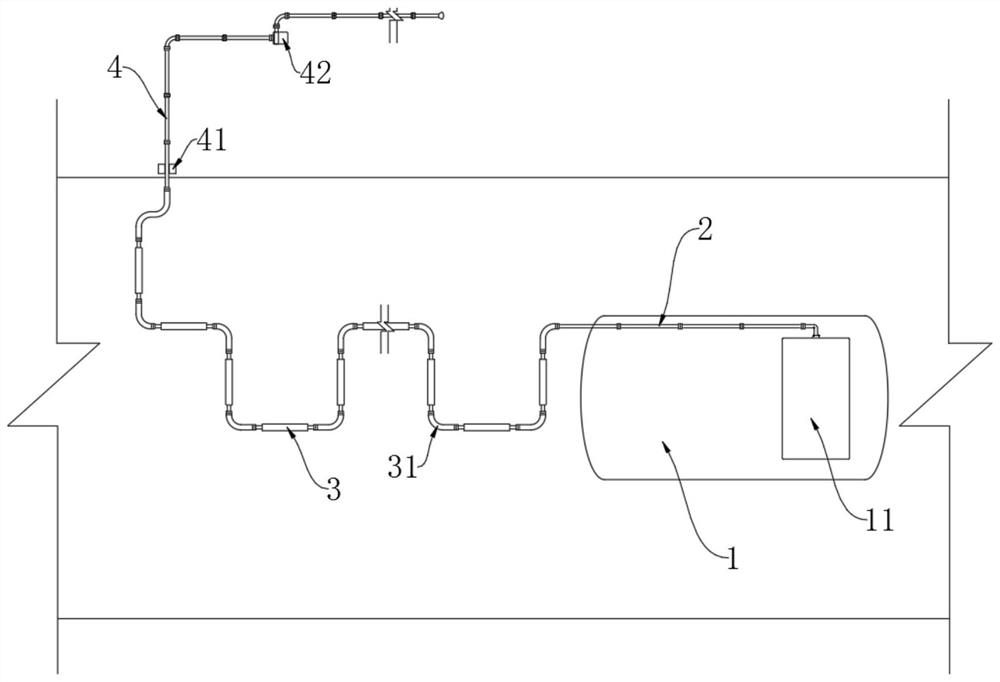

[0021] Example 1: Please refer to figure 1 As shown, the invention is a novel mud delivery pipeline for a cutter suction ship and its construction method, comprising a cutter suction ship 1, a mud suction device 11 is installed on the cutter suction ship 1, and the mud suction device 11 is used for dredging by the cutter suction ship 1. The reamer twists loose river bottom soil, and mud pump is sucked from mud suction pipe again, and it is mature existing device and present embodiment does not go into details again.

[0022] The present invention also includes three sections of mud delivery pipe 2 on board, water mud delivery pipe 3 and land mud delivery pipe 4;

[0023] The mud delivery pipe 2 on the ship is fixedly arranged on the cutter suction ship 1 and is connected with the dredging device 11, and the mud delivery pipe 2 on the ship is composed of multiple steel pipes, and is tightly connected by steel pipe joints to ensure smoothness and avoid dead bends.

[0024] The ...

Embodiment 2

[0027] Embodiment two: on the basis of above-mentioned embodiment one, disclose its construction method:

[0028] The first step is to prepare appropriate amount of materials according to the project to be constructed;

[0029] In the second step, on the cutter suction ship 1, the mud delivery pipe 2 on board is erected, the land mud delivery pipe 4 is laid on the land beside the river course under construction, and the water mud delivery pipe 3 is laid on the river course under construction;

[0030] In the third step, the two ends of the mud delivery pipe 3 on the water are respectively connected with the mud delivery pipe 2 on the ship and the mud delivery pipe 4 on land;

[0031] The fourth step, start construction;

[0032] The fifth step, during the construction process, along with the construction process of the cutter suction ship 1, lengthen or disassemble the steel pipes piercing the buoy, and then increase or decrease the length of the mud delivery pipe 3 on the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com