Fluidized limestone conveying system

A limestone and conveying system technology, applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of reducing the service life of conveying pipelines, reducing efficiency, and slow conveying speed, so as to achieve rational use of energy and avoid Partial clogging of pipelines and the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

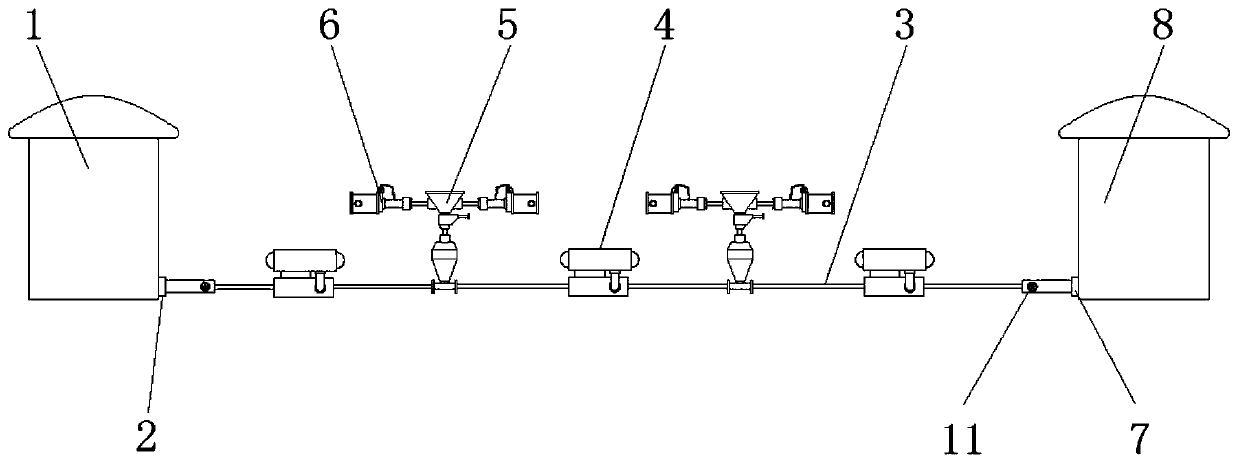

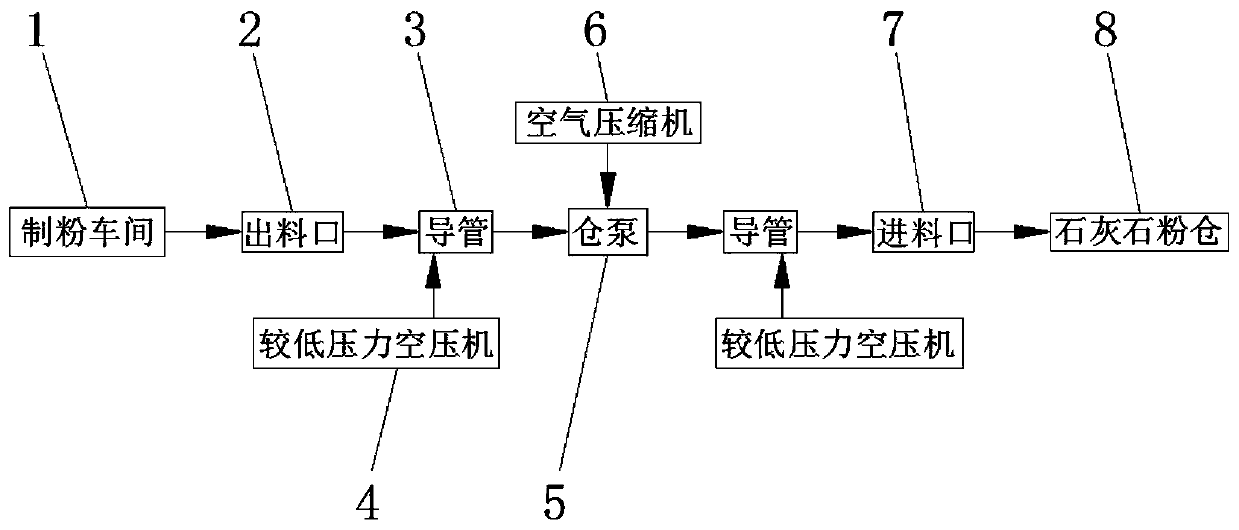

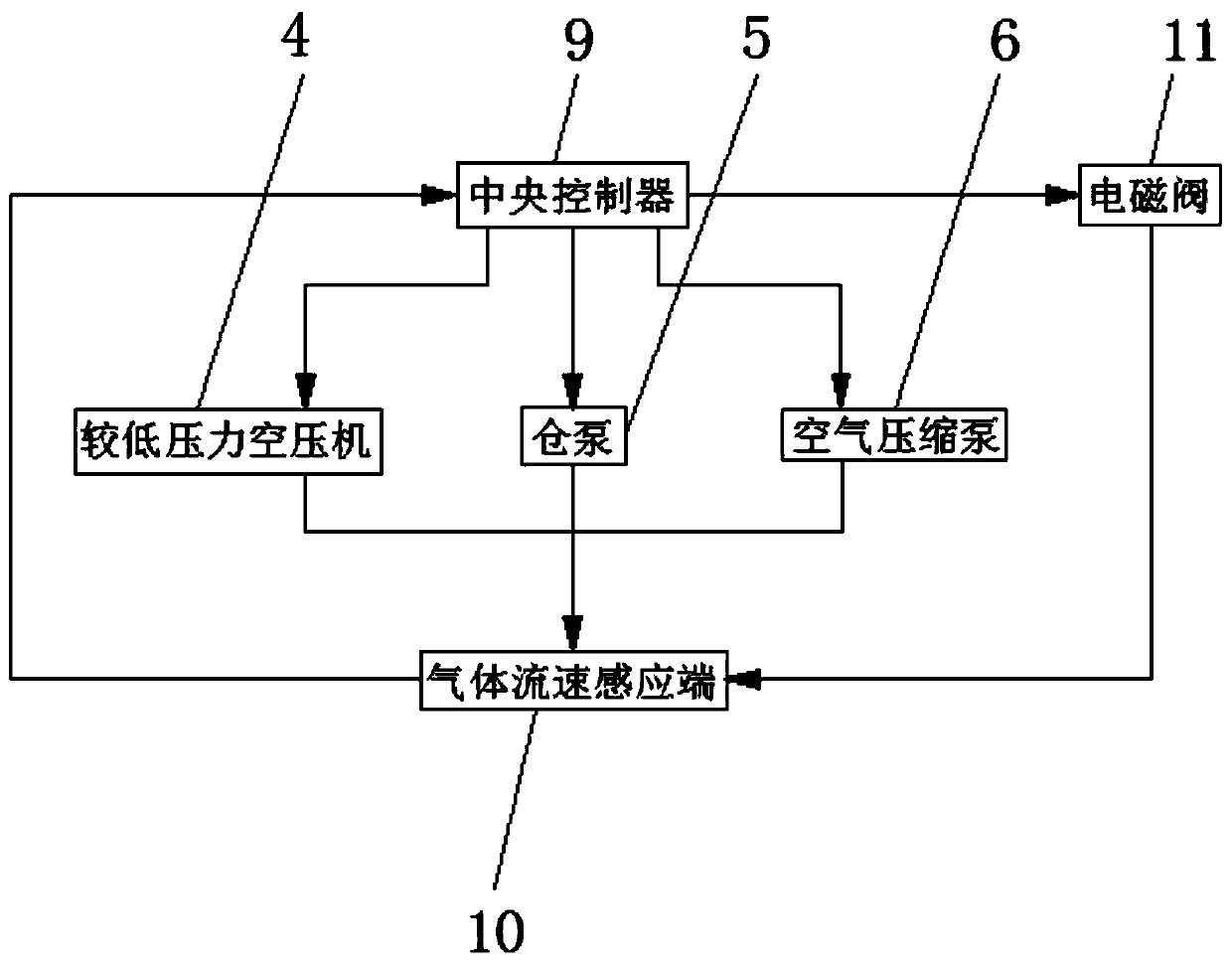

[0027] see Figure 1-3 , a fluidized limestone conveying system, comprising a discharge port 2 provided at the bottom of the milling workshop 1, a conduit 3 is provided on the inner thread of the discharge port 2, a warehouse pump 5 is installed at the other end of the conduit 3, and a warehouse pump 5 is installed on the other end of the conduit 3 The discharge port is connected with a limestone powder bin 8 through another conduit 3 , an air compressor 6 is installed at the vent on the top of the bin pump 5 , the end of the conduit 3 is connected with a lower pressure air compressor 4 , and the bottom of the limestone powder bin 8 There is a feed port 7, the inside of the feed port 7 is sealed with the end of the conduit 3, the input end of the warehouse pump 5 is electrically connected to the central processing unit 9, and the output end of the central processing unit 9 is connected to the lower pressure air compressor. The input ends of the air compressor 4 and the air com...

Embodiment 2

[0035] see Figure 1-3 , a fluidized limestone conveying system, comprising a discharge port 2 provided at the bottom of the milling workshop 1, a conduit 3 is provided on the inner thread of the discharge port 2, a warehouse pump 5 is installed at the other end of the conduit 3, and a warehouse pump 5 is installed on the other end of the conduit 3 The discharge port is connected with a limestone powder bin 8 through another conduit 3 , an air compressor 6 is installed at the vent on the top of the bin pump 5 , the end of the conduit 3 is connected with a lower pressure air compressor 4 , and the bottom of the limestone powder bin 8 There is a feed port 7, the inside of the feed port 7 is sealed with the end of the conduit 3, the input end of the warehouse pump 5 is electrically connected to the central processing unit 9, and the output end of the central processing unit 9 is connected to the lower pressure air compressor. The input ends of the air compressor 4 and the air com...

Embodiment 3

[0043] see Figure 1-3 , a fluidized limestone conveying system, comprising a discharge port 2 provided at the bottom of the milling workshop 1, a conduit 3 is provided on the inner thread of the discharge port 2, a warehouse pump 5 is installed at the other end of the conduit 3, and a warehouse pump 5 is installed on the other end of the conduit 3 The discharge port is connected with a limestone powder bin 8 through another conduit 3 , an air compressor 6 is installed at the vent on the top of the bin pump 5 , the end of the conduit 3 is connected with a lower pressure air compressor 4 , and the bottom of the limestone powder bin 8 There is a feed port 7, the inside of the feed port 7 is sealed with the end of the conduit 3, the input end of the warehouse pump 5 is electrically connected to the central processing unit 9, and the output end of the central processing unit 9 is connected to the lower pressure air compressor. The input ends of the air compressor 4 and the air com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com