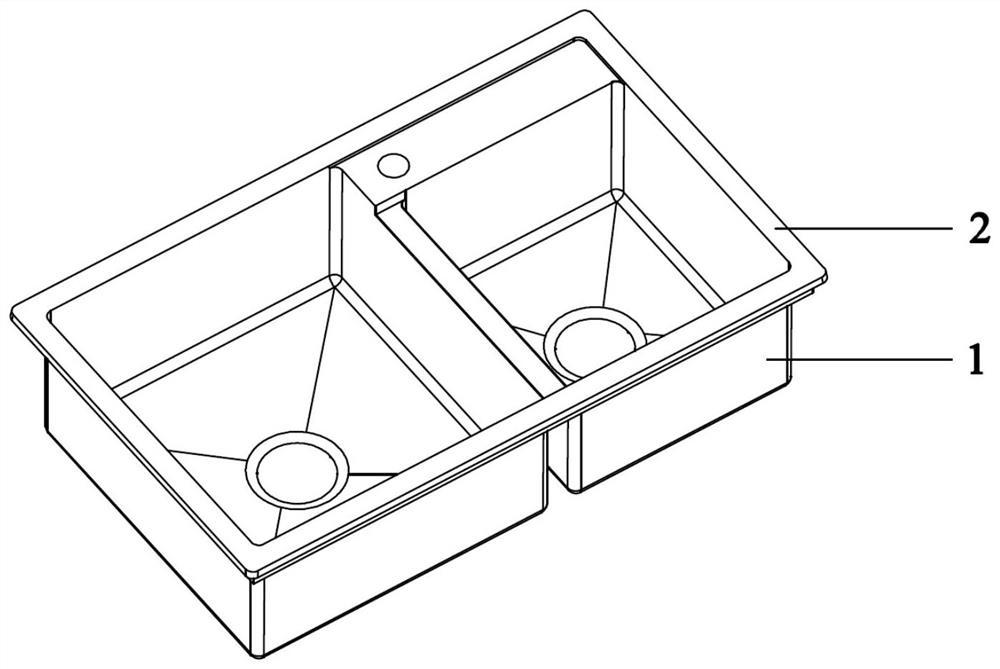

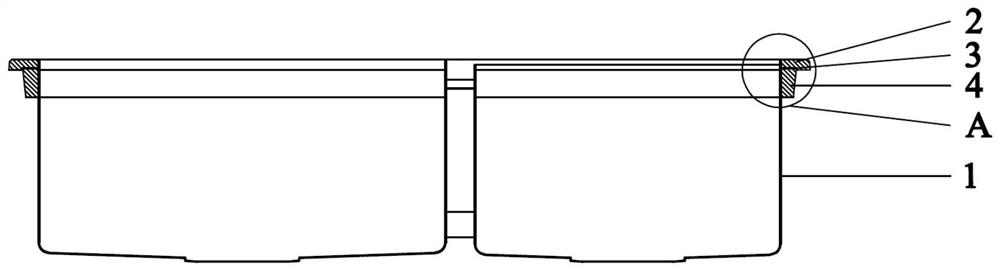

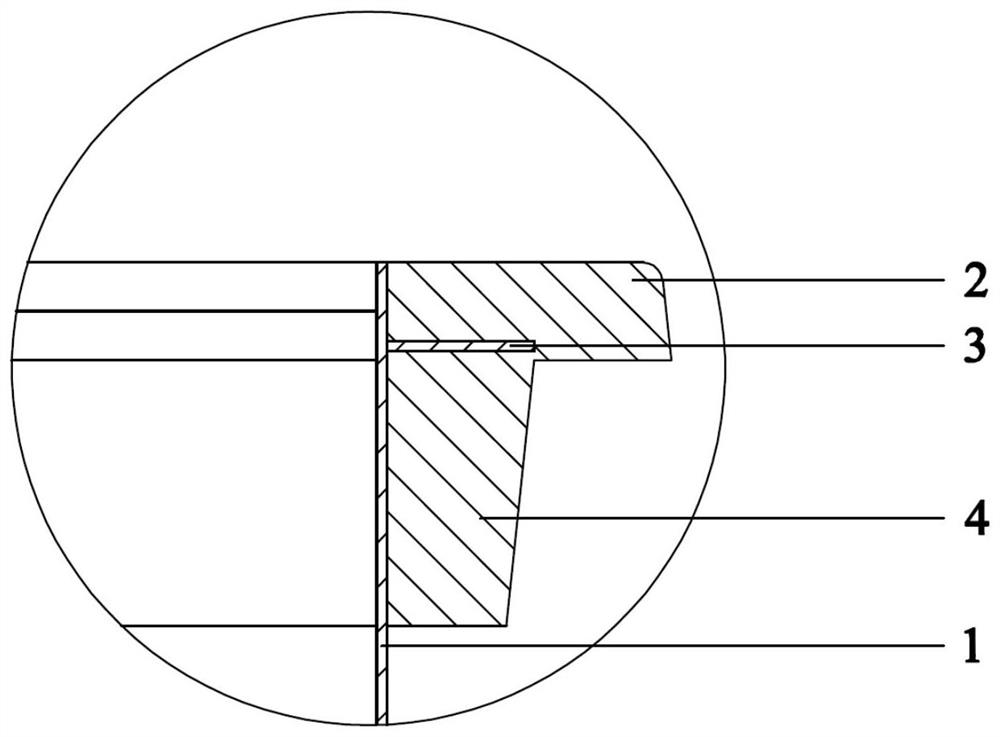

Kitchen sink with metal basin container embedded in quartz stone panel and manufacturing method of kitchen sink

A kitchen sink and the technology of its manufacturing method are applied in water supply installations, indoor sanitary plumbing installations, buildings, etc., which can solve the problems of uneven surface of stainless steel sink panels, loose contact of cabinet countertops, and easy breeding of mold, etc., and achieve easy cleaning , stable connection and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The raw materials of colored quartz stone panels include 24% of quartz sand powder, 56% of colored quartz sand, 1.5% of silane coupling agent, 0.7% of accelerator, 1.3% of catalyst and 16.5% of unsaturated resin in terms of mass percentage. The stone panel is not easy to deform, has a smooth surface, is not easy to crack, has good compression resistance, and is firmly connected with the metal basin.

Embodiment 2

[0046] The raw materials of the colored quartz stone panel include 28% of quartz sand powder, 45% of colored quartz sand, 0.6% of silane coupling agent, 0.5% of dispersant, 0.1% of antioxidant, 0.8% of defoaming agent, and 1.5% of accelerator by mass percentage , 1.5% catalyst and 22% unsaturated resin, the colored quartz stone panel produced is not easy to deform, has good toughness, is not easy to crack, has good compression resistance, and is firmly connected with the metal basin.

Embodiment 3

[0048]The raw materials of colored quartz stone panel include 22% of quartz sand powder, 44% of colored quartz sand, 1% of silane coupling agent, 1% of dispersant, 0.2% of antioxidant, 0.8% of defoaming agent, and 1% of accelerator by mass percentage , 2% catalyst and 28% unsaturated resin, the colored quartz stone panel produced is not easy to deform, has good toughness, is not easy to crack, has good compression resistance, and is firmly connected with the metal basin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section width | aaaaa | aaaaa |

| Cross section height | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap