Manufacturing method of tooth difference speed reducer of double-row planetary gear

A double-row planetary and reducer technology, applied in the field of high precision, can solve the problems of small reduction ratio of the reducer, low transmission accuracy, heavy weight, etc., and achieve the effect of large reduction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

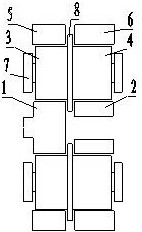

[0013] figure 1 In the shown embodiment, the front sun gear (1) inputs power, the rear sun gear (2) follows, and the front planetary gear (3) and the rear planetary gear (4) are connected and installed on the planet carrier (7) Among them, the front row ring gear (5) and the rear row ring gear (6) each fix an output power.

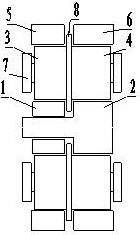

[0014] exist figure 2 In the shown embodiment, the rear row of sun gears (2) input power, the front row of sun gears (1) follow up, the front row of planetary gears (3) and the rear row of planetary gears (4) are connected and installed on the planet carrier (7) Among them, the front row ring gear (5) and the rear row ring gear (6) each fix an output power.

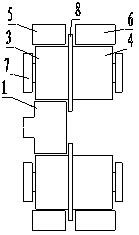

[0015] exist image 3 In the shown embodiment, there is no rear row sun gear (2), the front row sun gear (1) inputs power, and the front row planetary gear (3) is connected with the rear row planetary gear (4) and installed in the planet carrier (7) , the front row ring gear (5) and the rear row ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap