Polygonal-section bridge pier stud reinforcement cage integral hoisting and binding jig and using method

A steel cage hoisting and overall hoisting technology, which is applied in the direction of applications, household appliances, and other household appliances, can solve the problems of reducing construction efficiency, consuming a lot of time and labor, and achieving the goals of controlling the spacing of steel bars, fast binding, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

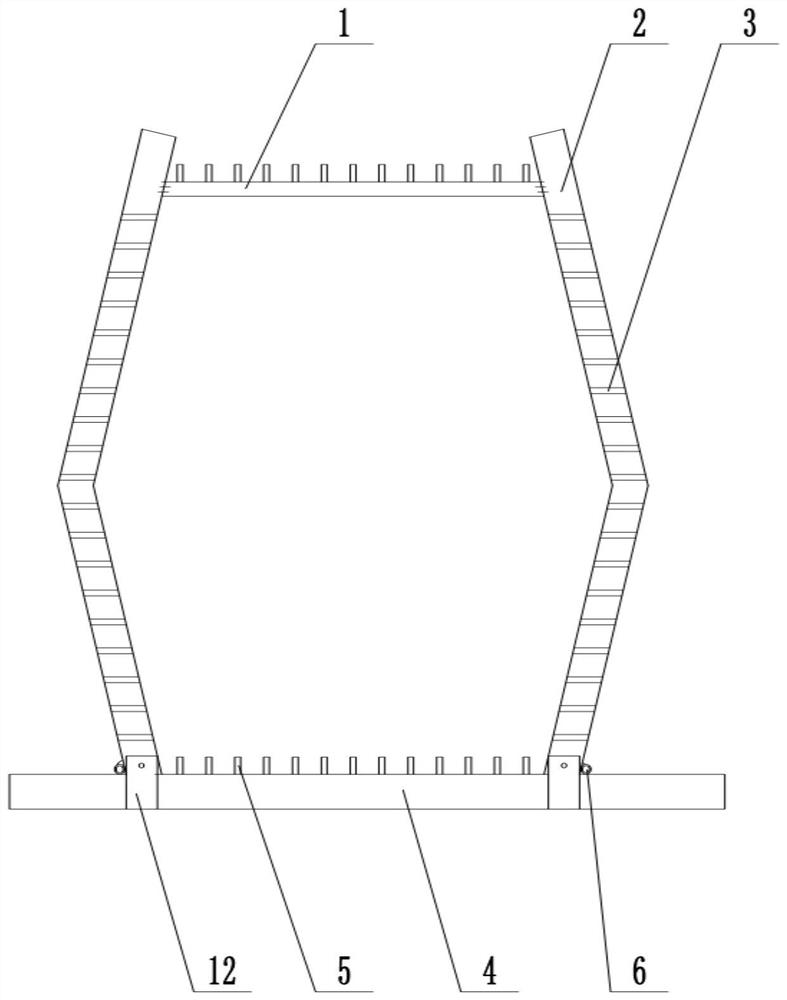

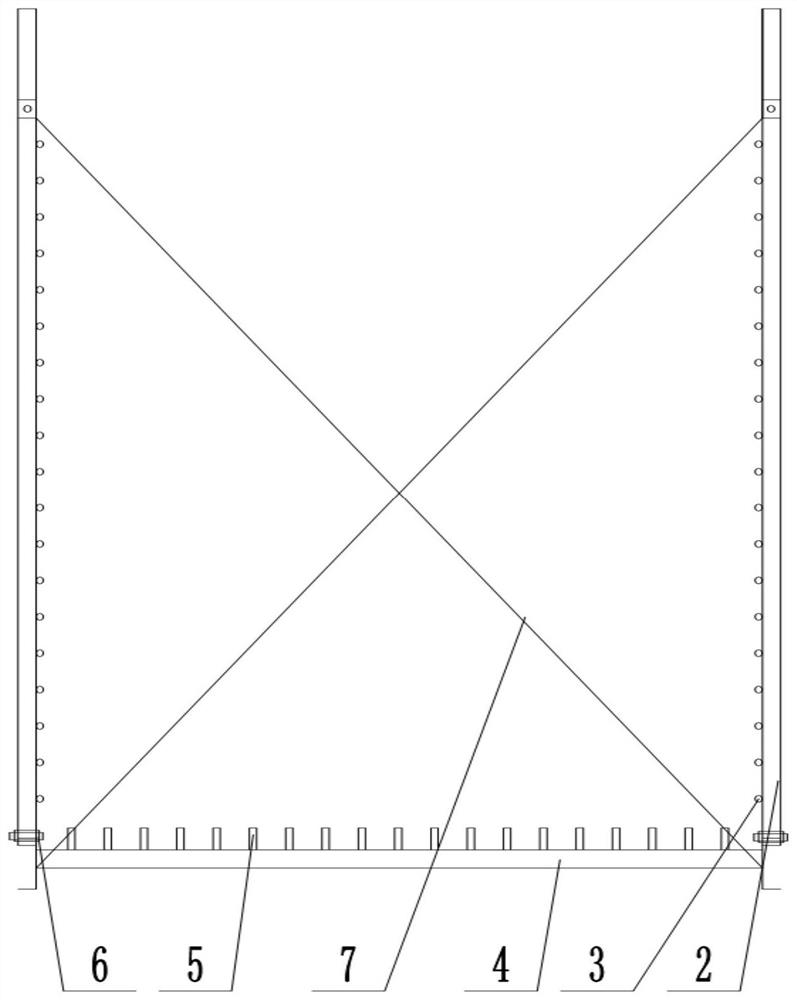

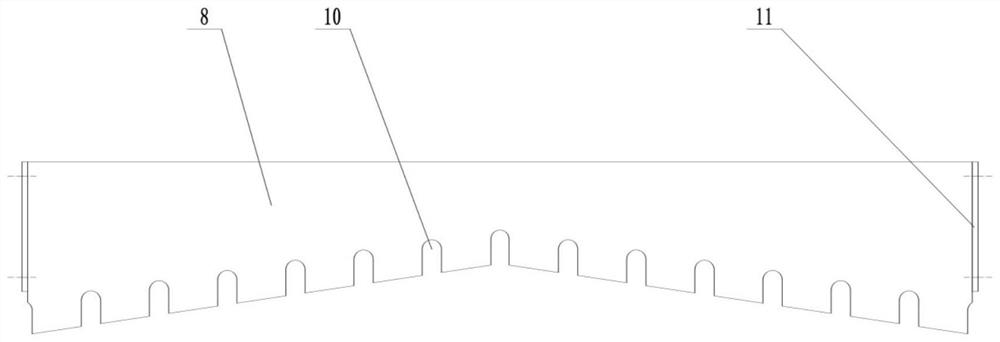

[0029] The overall hoisting and binding of the steel cage of the bridge pier column with polygonal cross-section includes a fixed limit bottom plate 4, a detachable limit side plate 2 and a detachable limit top plate 1, and the fixed limit bottom plate 4 is divided into a horizontal limit bottom plate And the longitudinal limit bottom plate, the short round steel ends 5 are arranged on the horizontal limit bottom plate with the designed reinforcement cage main reinforcement spacing, and the round steel short ends 5 are arranged at the designed reinforcement cage stirrup spacing on the longitudinal limit bottom plate, detachable limit One end of the side plate 2 is detachably connected to both sides of the fixed limit base plate 4, and the plate surface of the detachable limit side plate 2 is provided with thin steel pipes 3 at the designed spacing between the vertical main bars of the reinforcement cage. The other end of the plate 2 is connected with bolts at both ends of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com