Construction method for basement buttress stirrups and steel plate waterstops

A steel plate waterstop and construction method technology, applied in the processing of building materials, construction, building components, etc., can solve the problems of increasing the amount of concrete, increasing the section of the column, and increasing the cost, so as to improve the quality of the project and facilitate adjustment distance, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

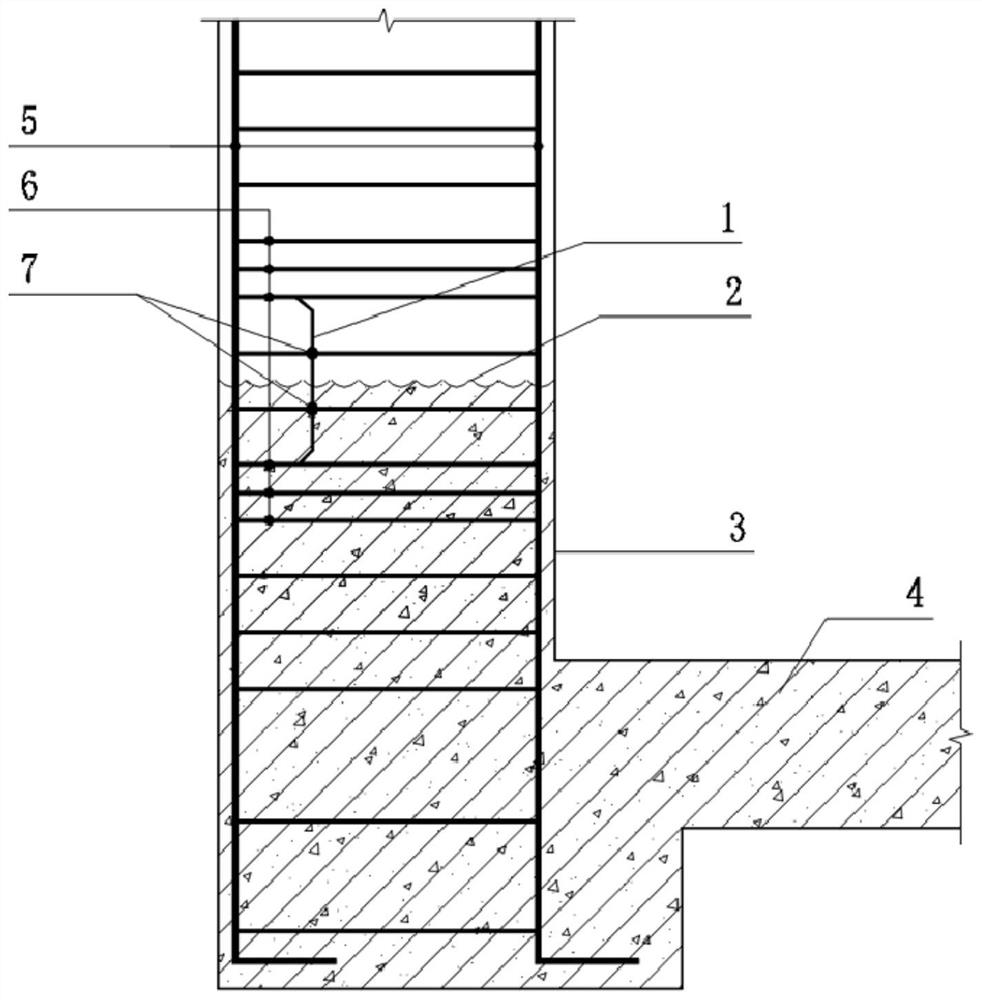

[0033] The present embodiment provides a construction method for a basement buttress column stirrup and a steel plate waterstop, including the following steps:

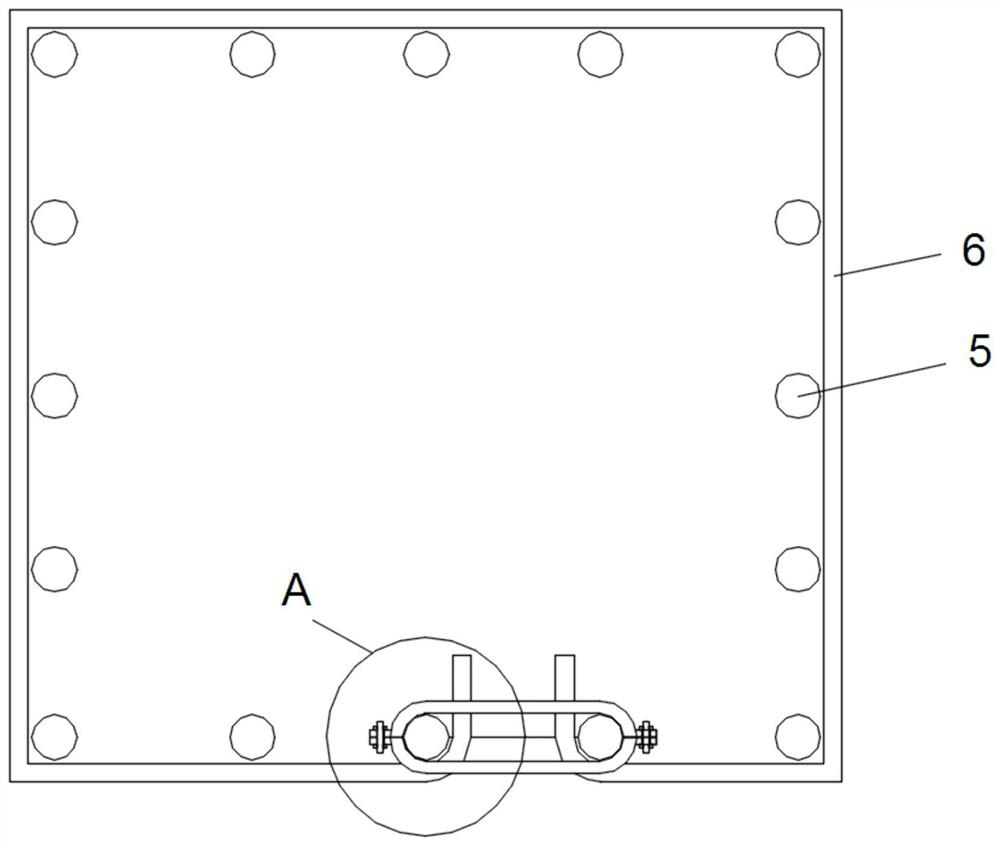

[0034] S1. First construct the basement floor steel bars, retaining wall steel bars, buttress column longitudinal bars 5 and buttress column stirrups 6 below the bottom edge of the steel plate water stop 2;

[0035] S2, install the steel plate water stop 2;

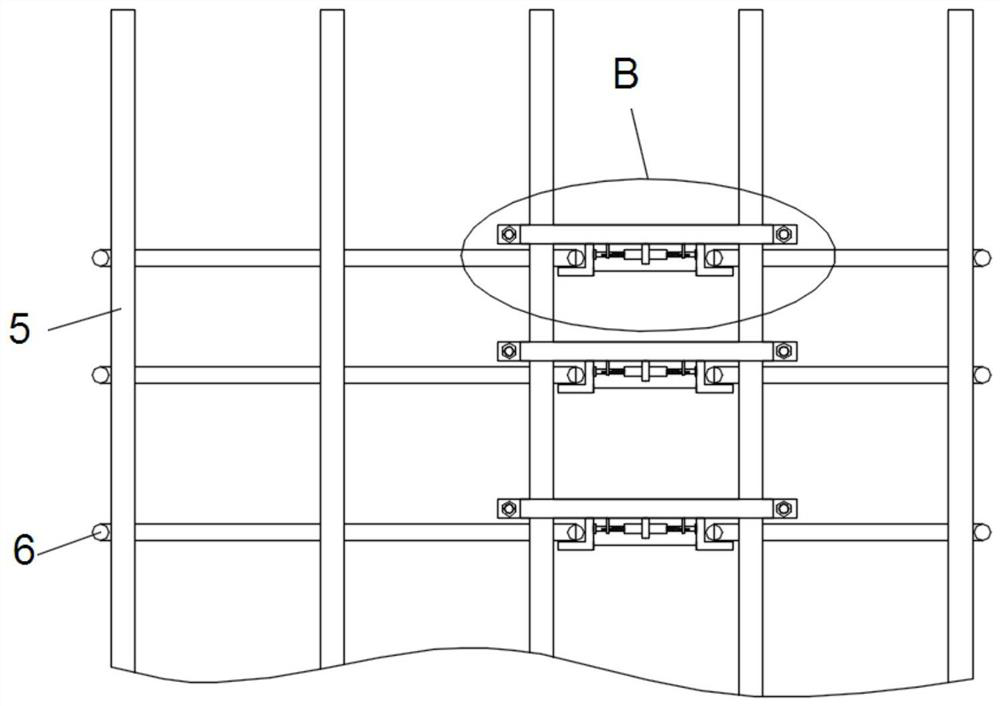

[0036] S3, install the buttress column stirrups 6 that conflict with the steel plate waterstop 2, and the buttress column stirrups 6 are spot welded with the steel plate waterstop at the place where the buttress column stirrups are cut off by the steel plate waterstop;

[0037] S4. Install buttress column stirrups 6 above the top edge of the steel plate waterstop 2;

[0038] S5, continue to install transverse stirrups above the buttress column stirrups 6;

[0039] S6. After the formwork is installed, concrete pouring and maintenance are performed in sequence. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com