Construction method of fast positioning and binding trolley for steel bars in full circular inclined shaft

A technology for inclined shafts and steel bars, which is applied in shaft equipment, shaft lining, earthwork drilling and mining, etc. It can solve problems such as difficulty in ensuring that the circumferential steel bars are perpendicular to the axis, difficulty in ensuring construction quality accuracy, and high labor intensity in construction, so as to achieve construction efficiency. High, speed up construction efficiency, improve the effect of construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

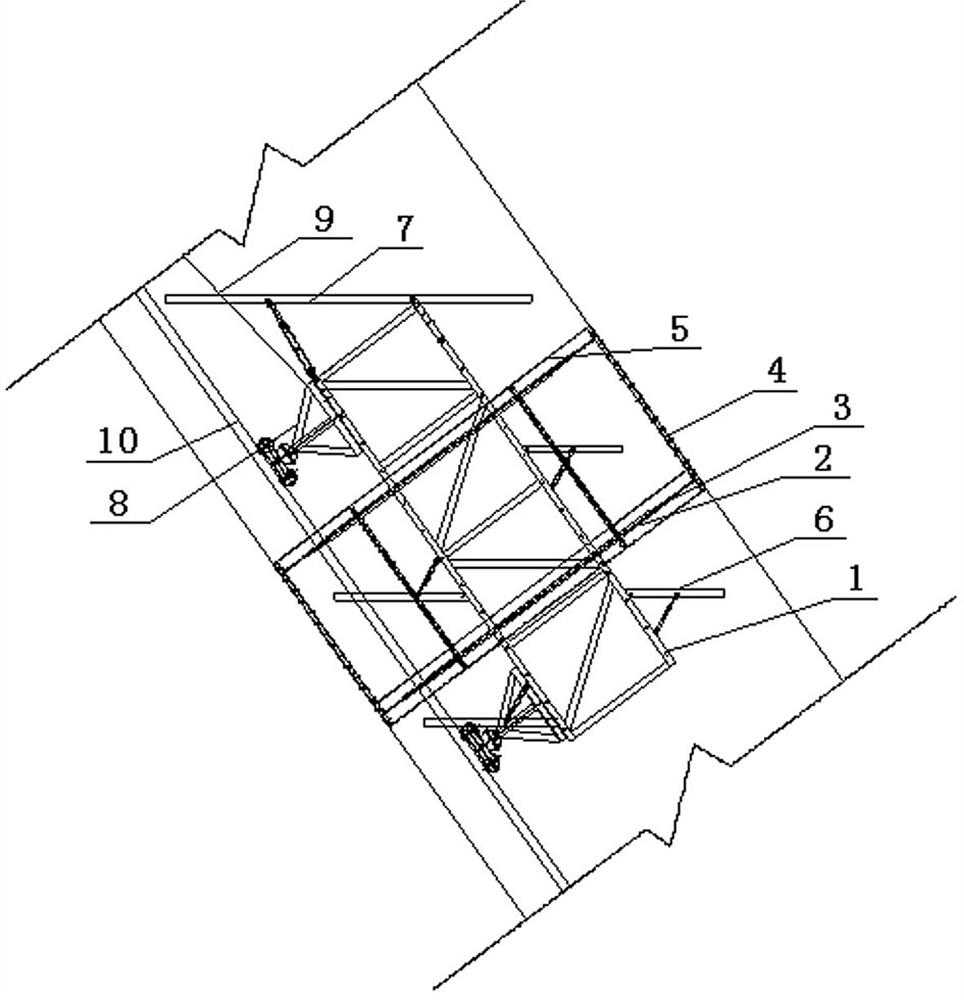

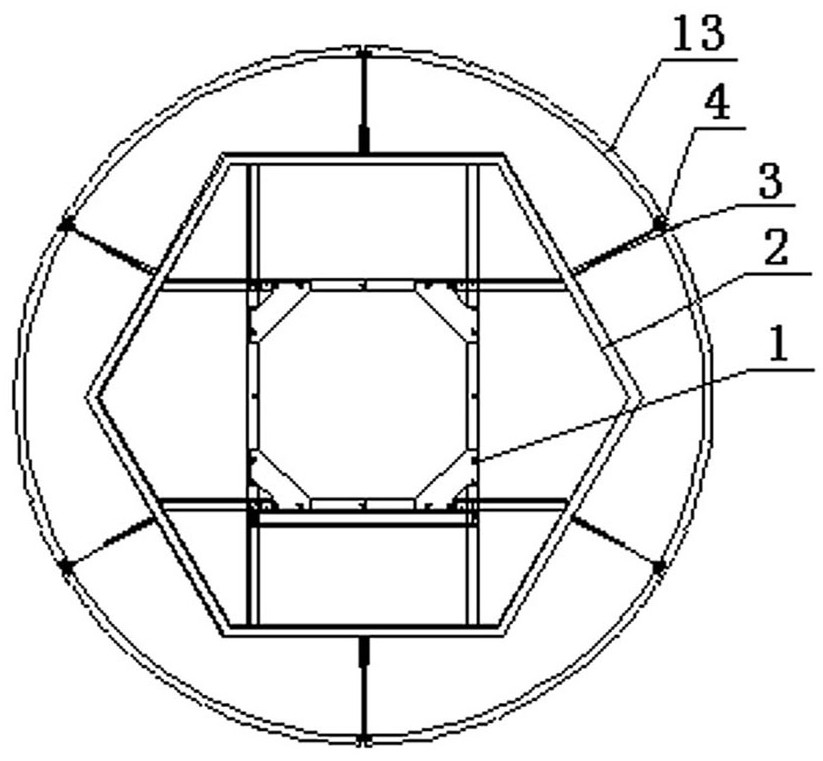

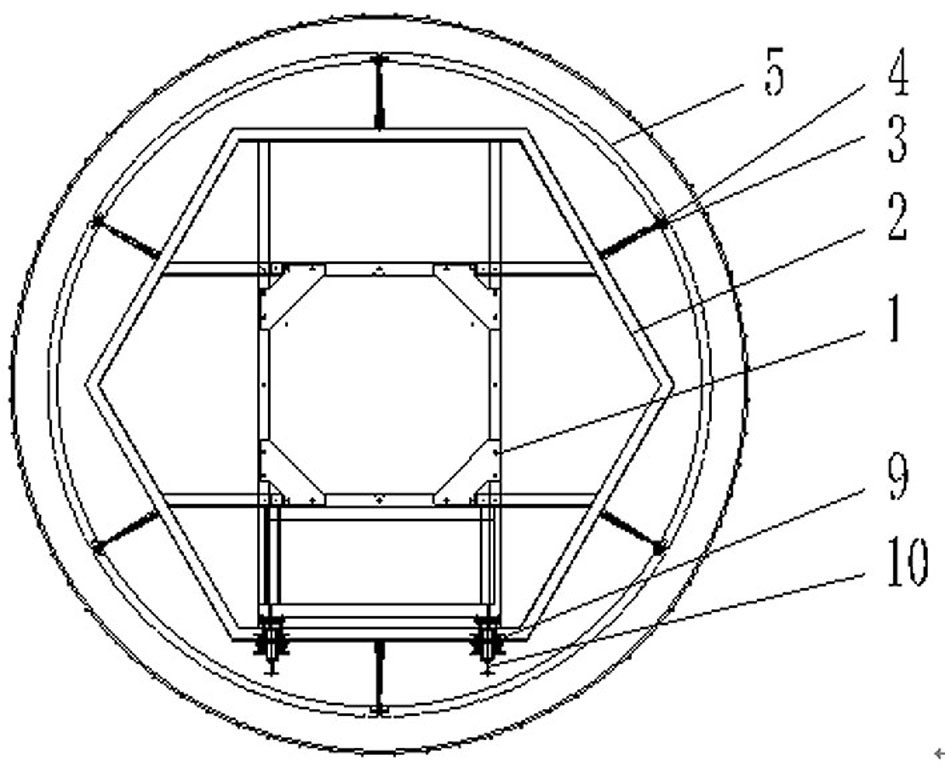

[0037] A fast positioning and binding trolley for steel bars in a full-circle inclined shaft will be described in detail in conjunction with the accompanying drawings.

[0038] The present invention mainly realizes from the following aspects:

[0039] A trolley for quickly positioning and binding steel bars in a full-circle inclined shaft includes a frame beam 1, a regular polygonal ring beam 2, an adjusting screw 3, a circumferential steel bar positioning device 4, a longitudinal steel bar positioning plate, an operating platform 6, and a top stacking platform 7, Road wheel system 8, traction system 9.

[0040] The operation platform 6 is arranged around the frame beam 1, two are arranged on each floor. The operation platform is a retractable structure, which meets the requirements for the binding construction of inner and outer layers of steel bars. The platform is designed as an adjustable structure, and the top stacking platform 7 is fixed on the front end of the frame bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com