Paperboard cutting device

A technology of cutting device and paper feeding device, which is used in transportation and packaging, object supply, metal processing, etc., can solve the problems of easy operator fatigue, high cutting cost, low paper feeding efficiency, etc. Best, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through specific implementations:

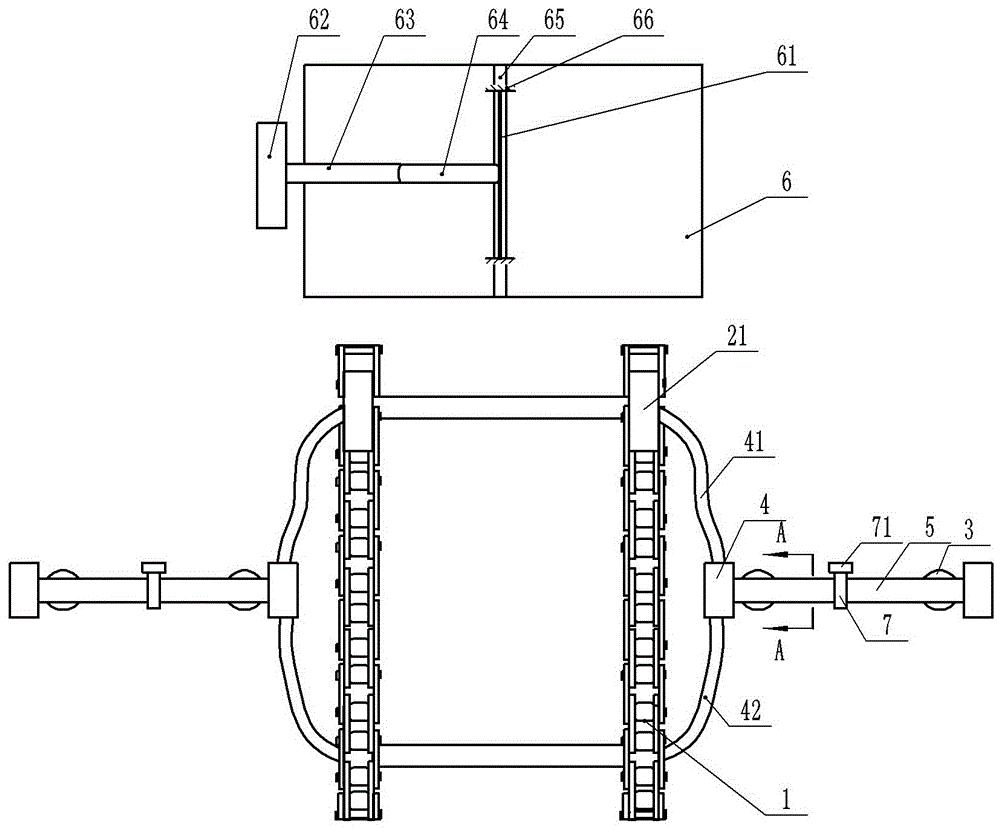

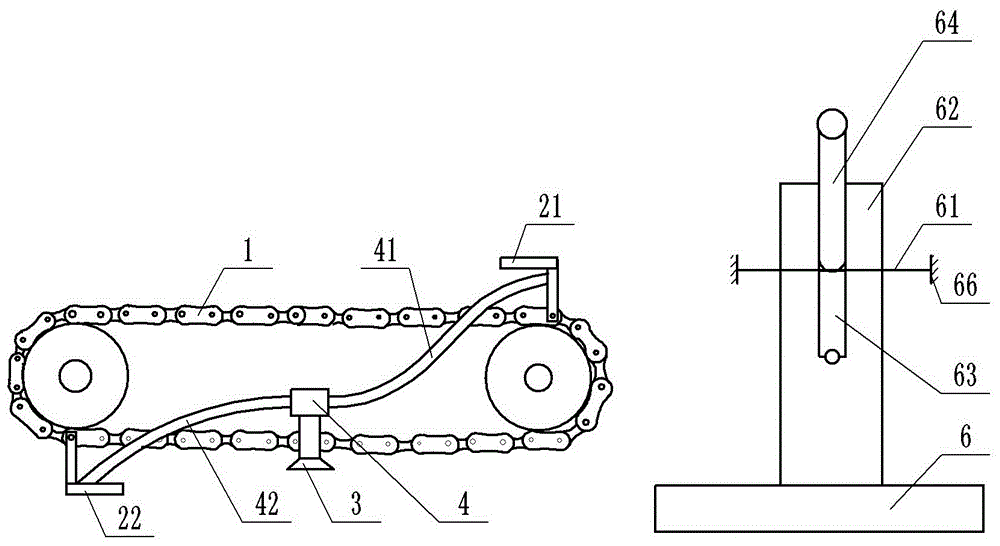

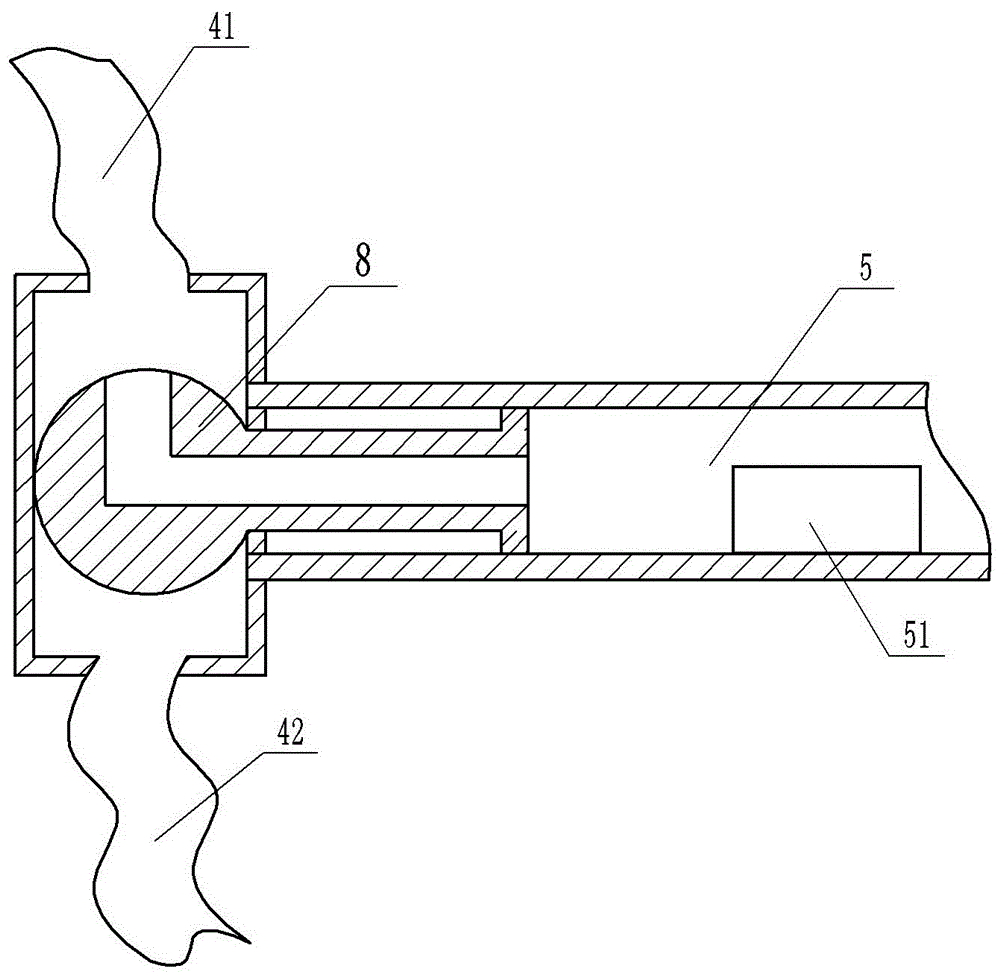

[0020] The reference signs in the drawings of the specification include: conveyor chain 1, first paper pushing claw 21, second paper pushing claw 22, first clamping plate 23, second clamping plate 24, groove 25, airbag 26, spring 27. Limit block 28, suction nozzle 3, rotating sleeve 4, first pipe 41, second pipe 42, rigid pipe 5, air extraction device 51, working table 6, cutting knife 61, frame 62, first rotating rod 63. The second rotating rod 64, the groove 65, the guide groove 66, the solenoid valve 7, the solenoid valve controller 71, and the valve core 8.

[0021] Such as figure 1 , figure 2 As shown, a cardboard cutting device includes a frame 62, a paper feeding device, a cutting unit, and a worktable. The cutting unit is fixed on the frame 62 and is located above the worktable 6, and the paper feeding device is located on a side of the worktable 6. side. The cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com