Rapid clamp structure with lock

A fast and lockable technology, applied in the direction of clamps, manufacturing tools, etc., can solve the problems of high production cost, poor self-locking reliability, complex organization process, etc., and achieve the effect of low structural cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

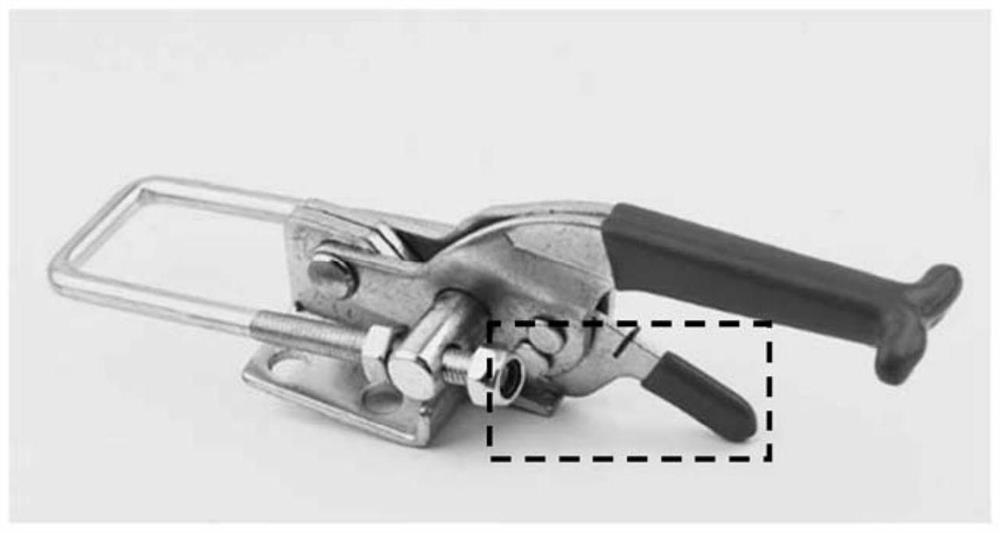

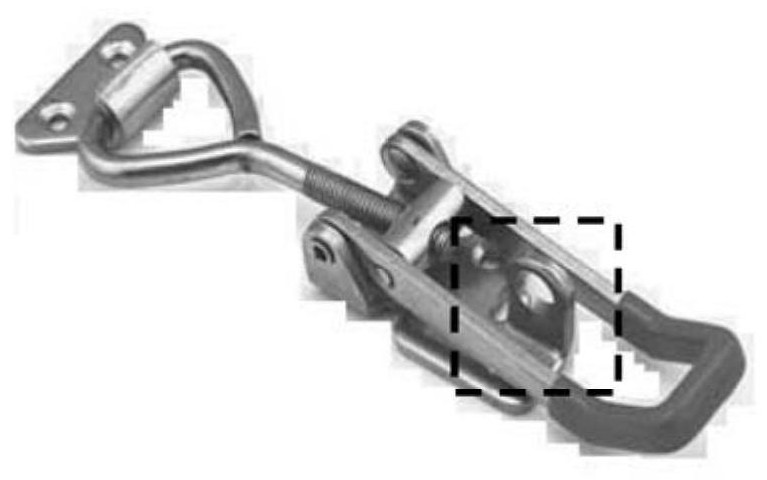

[0031] Quick clamps and quick clamps are tools that can fix, connect, fasten, and push in industrial production. Quick clamps are divided into horizontal type, vertical type, push-pull type, gate type, vertical type, extrusion clamp, C-type clamp, F-type clamp, etc., which can be widely used in various manufacturing and processing industries.

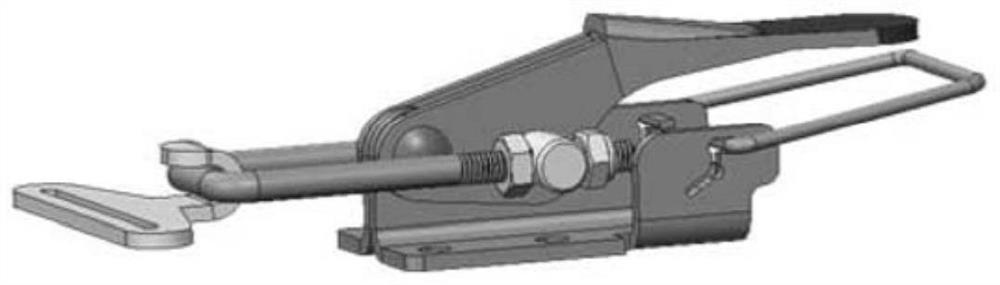

[0032] The technical problem to be solved by the present invention is: to provide a quick clamp with a lock that is easy to use and low in cost, that is, a lock rod is added to form a quick clamp with a lock with the inclined groove path of the main body. It is necessary to move the lock lever according to the designed chute path to prevent the clamp from loosening, such as image 3 and Figure 4 shown.

[0033] Figure 5 It is a schematic structural diagram of a quick clamp with a lock according to an embodiment of the present invention.

[0034] The quick clamp with lock according to the embodiment of the present invention include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com