Pin-feeding manipulator mechanism for assembling electric appliance switch piece

A technology of electrical switches and manipulators, applied in manipulators, packaging, distribution devices, etc., can solve the problems of low efficiency, high cost, and failure to meet the actual needs of enterprises, so as to make up for low efficiency, clear working principles, and realize product production automation and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

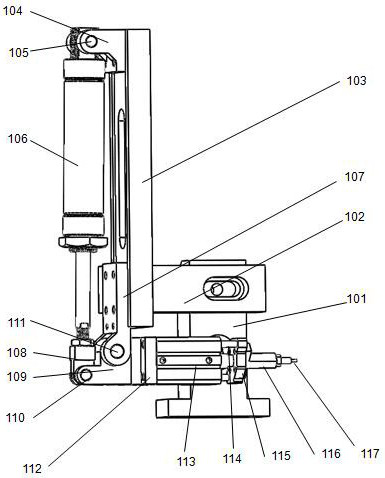

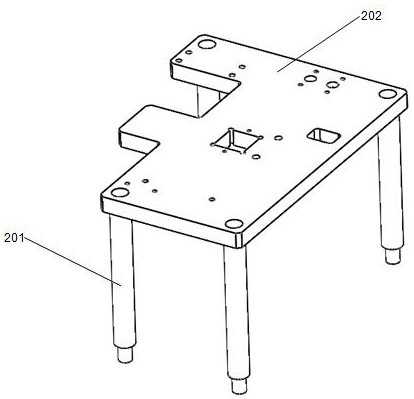

[0012] like Figure 1-2 As shown, a nailing manipulator mechanism is used for the assembly of electrical switch parts. The nailing manipulator mechanism is composed of a first nailing manipulator fixing plate 101, a second nailing manipulator fixing plate 102, a first cylinder support 103, a first cylinder seat 104, First column pin 105, first cylinder 106, hinge seat 107, rotary drive block 108, turn block 109, second column pin 110, third column pin 111, second cylinder mounting plate 112, second cylinder 113, guide rod 114, the magnet mounting plate 115, the magnet seat 116 and the magnet 117 are composed; the second nailing manipulator fixed plate 102 is fixedly arranged on the first nailing manipulator fixing plate 101, and the first cylinder support 103 is fixedly arranged on the second nailing manipulator. On the plate 102, the first cylinder seat 104 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com