Production process for reactive powder concrete sleeper structural member

A technology for reactive powder and structural components, which is applied in the field of production technology of reactive powder concrete sleeper structural components, can solve problems such as restricting the large-scale production and application of reactive powder concrete sleepers, achieves improved strength and durability, is easy to implement, and solves process bottlenecks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

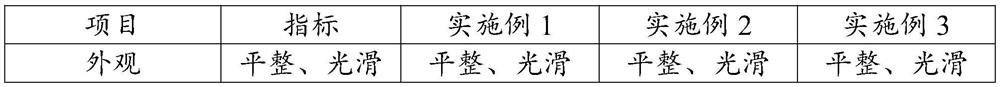

Embodiment 1

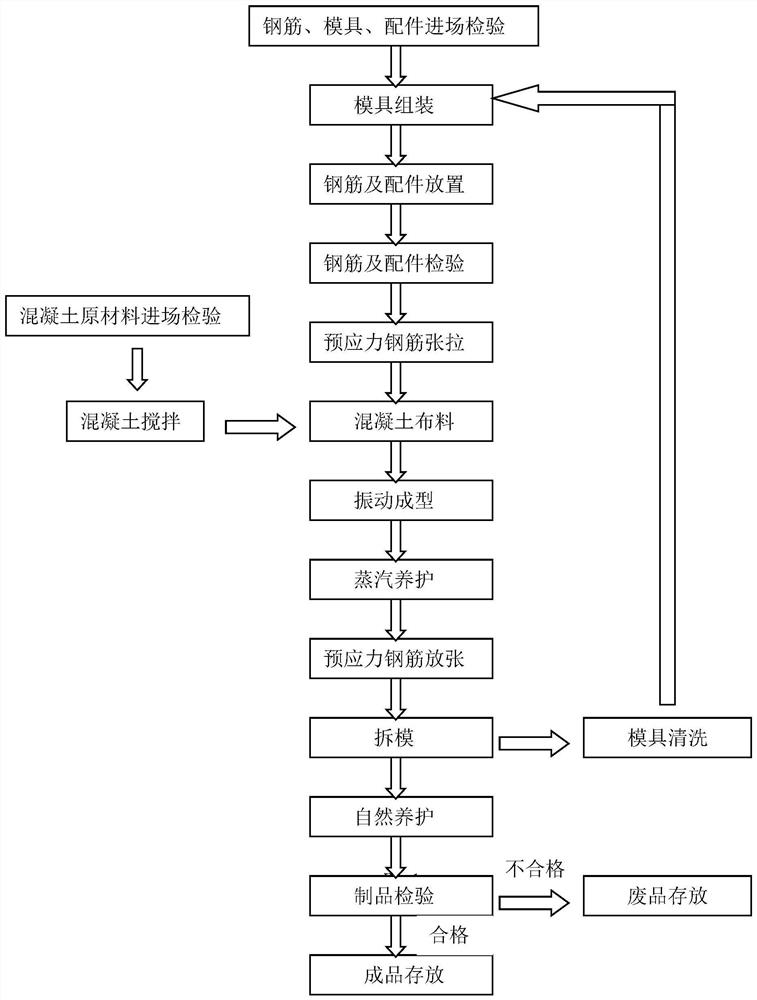

[0047] A production process of active powder concrete sleeper structural components, specifically comprising the following steps:

[0048] (1) Inspection: Send the steel molds of sleeper structural components, prestressed steel bars, tooling accessories, process accessories and reactive powder concrete raw materials into the site and inspect them;

[0049] Among them, the active powder concrete raw material is composed of the following raw materials in parts by weight: 700 parts of ordinary portland cement, 200 parts of admixture, 1200 parts of quartz sand, 120 parts of steel fiber, 60 parts of polycarboxylate superplasticizer and water 120 copies;

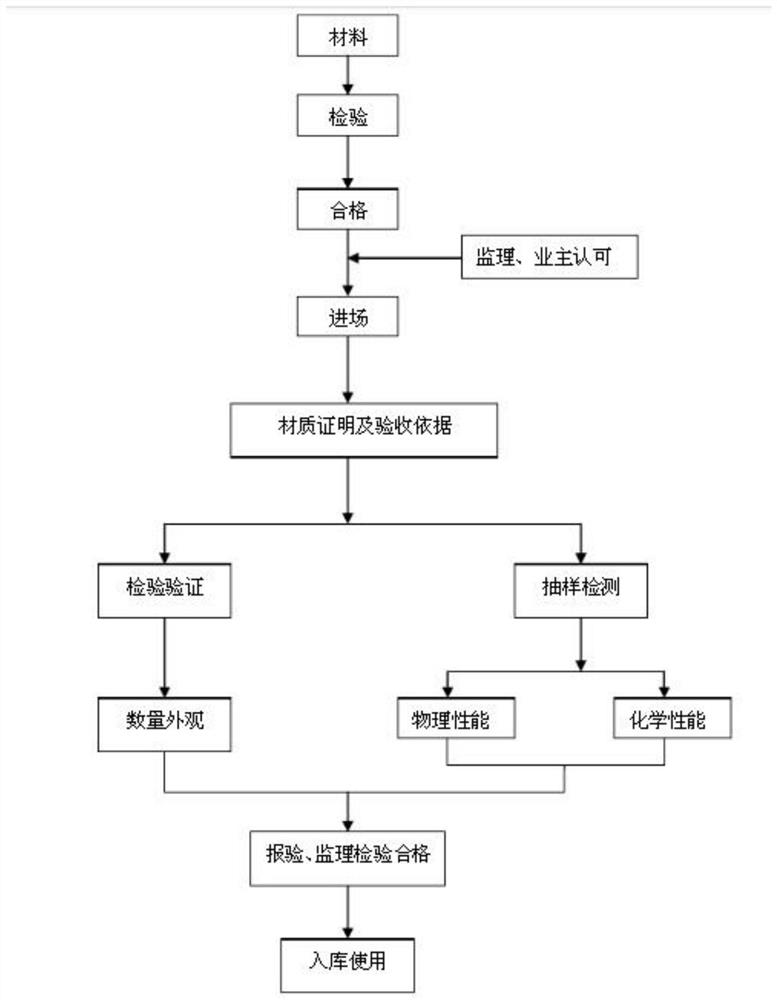

[0050] The specific process of sending to the site and inspection is as follows: figure 2 As shown, including: investigation and sampling inspection → selection of qualified suppliers → submission of material plan → organization of materials entering the site → preliminary inspection (clear out of the site for materials that fai...

Embodiment 2

[0069] A production process of active powder concrete sleeper structural components, specifically comprising the following steps:

[0070] (1) Inspection: Send the steel molds of sleeper structural components, prestressed steel bars, tooling accessories, process accessories and reactive powder concrete raw materials into the site and inspect them;

[0071] Among them, the active powder concrete raw material is composed of the following raw materials in parts by weight: 680 parts of ordinary portland cement, 190 parts of admixture, 1200 parts of quartz sand, 90 parts of steel fiber, 55 parts of polycarboxylate superplasticizer and water 120 copies;

[0072] The specific process of sending to the site and inspection is as follows: figure 2 As shown, including: investigation and sampling inspection → selection of qualified suppliers → submission of material plan → organization of materials entering the site → preliminary inspection (clear out of the site for materials that fail...

Embodiment 3

[0091] A production process of active powder concrete sleeper structural components, specifically comprising the following steps:

[0092] (1) Inspection: Send the steel molds of sleeper structural components, structural steel bars, tooling accessories, process accessories and reactive powder concrete raw materials into the site and inspect them;

[0093] Among them, the active powder concrete raw material is composed of the following raw materials in parts by weight: 700 parts of ordinary portland cement, 210 parts of admixture, 1180 parts of quartz sand, 140 parts of steel fiber, 55 parts of amino superplasticizer and 120 parts of water ;

[0094] The specific process of sending to the site and inspection is as follows: figure 2 As shown, including: investigation and sampling inspection → selection of qualified suppliers → submission of material plan → organization of materials entering the site → preliminary inspection (clear out of the site for materials that fail the prel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap