Anchor cable structure and anchor cable frame beam construction method

A technology of frame beams and anchor cables, applied in foundation structure engineering, building construction, sheet pile walls, etc., can solve problems such as the problem of hole formation in broken ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

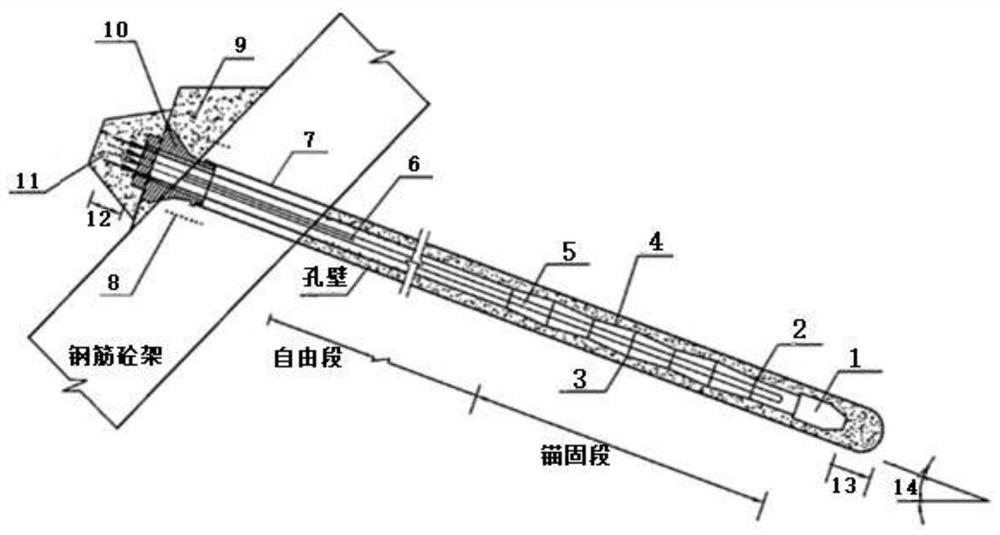

[0043] Embodiment 1: An anchor cable structure, including a guide cap 1, an anchor cable component, a tightening ring 2, a grouting pipe 5, an expansion ring 3, an anchor 10, a concrete anchor bracket 9, and an anchor head. The anchor cable component is divided into The free section and the anchor section, the top of the free section of the anchor cable is set on the reinforced concrete frame through the anchorage 10, the bottom end of the anchor section is fixedly connected with the guide cap 1, the anchor cable component includes a steel strand, and the free section of the steel strand is Oil-coated sheathed plastic steel strand 6, the anchoring section of the steel strand bundle is a bare steel strand, the steel strand bundle is bound into an anchor cable through uniformly arranged tight hoops 2, the grouting pipe 5 is arranged in the center of the anchor cable, and the anchorage of the anchor cable component The section is uniformly provided with an expansion ring 3 and the...

Embodiment 2

[0072] Embodiment 2: This embodiment is an anchor cable frame beam construction method in a highway project in Yunnan, using the anchor cable structure of Embodiment 1, and the specific steps are as follows:

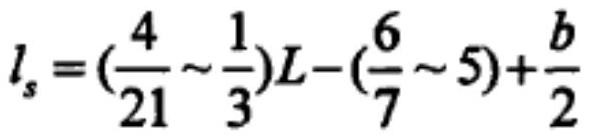

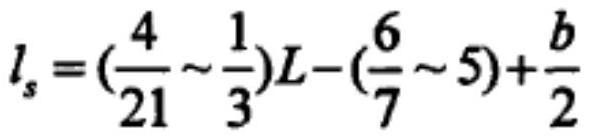

[0073] (1) The slope surface shall be cleared according to the design slope rate, and the anchor hole spacing, inclination and elevation of the anchor cable frame beam shall be designed according to the slope height and geological conditions, and the vertical and transverse rib column positions shall be determined; Among them, the specific design method of the anchor hole spacing, inclination and elevation of the anchor cable frame beam: the inclination and elevation of the anchor cable frame beam are determined according to the inclination and height of the slope surface; due to the strong anchoring force of the prestressed anchor cable, the slope The extrusion anchorage zone is formed in the slope. From the stability analysis of the slope, the sliding surface or potenti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com