Well bore structure penetrating through high-pressure layer and basalt collapse layer and construction method of well bore structure

A wellbore structure and construction method technology, applied in drilling equipment, earthwork drilling, wellbore/well components, etc., can solve the problems of wellbore collapse, overflow and lost circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

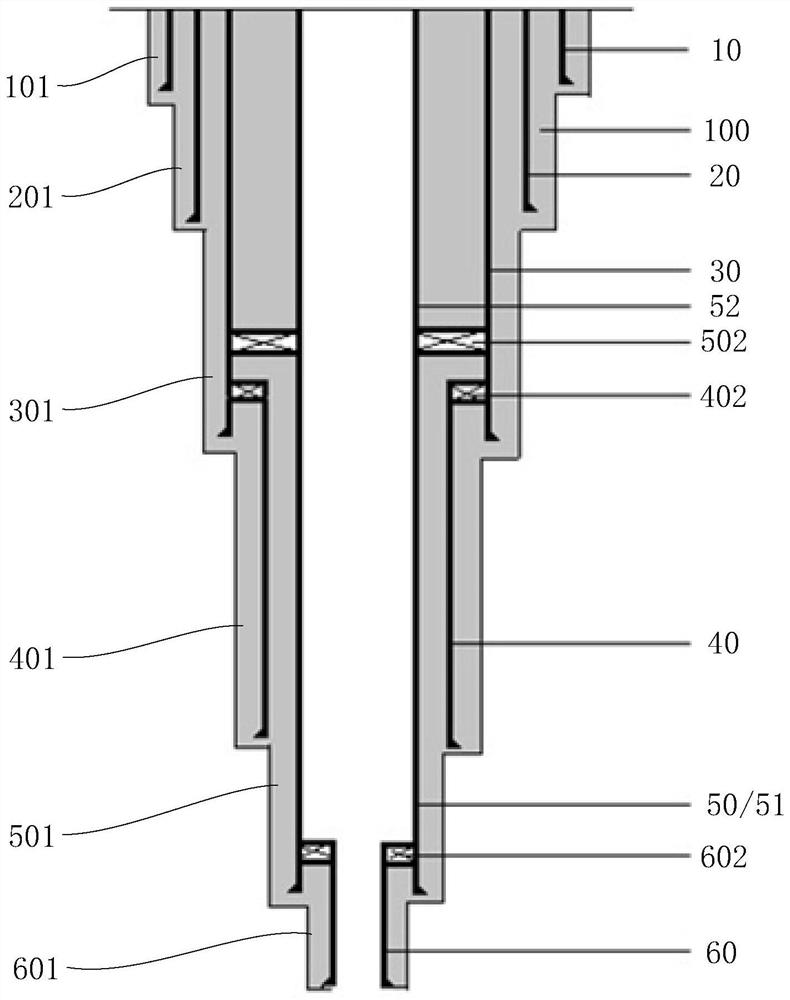

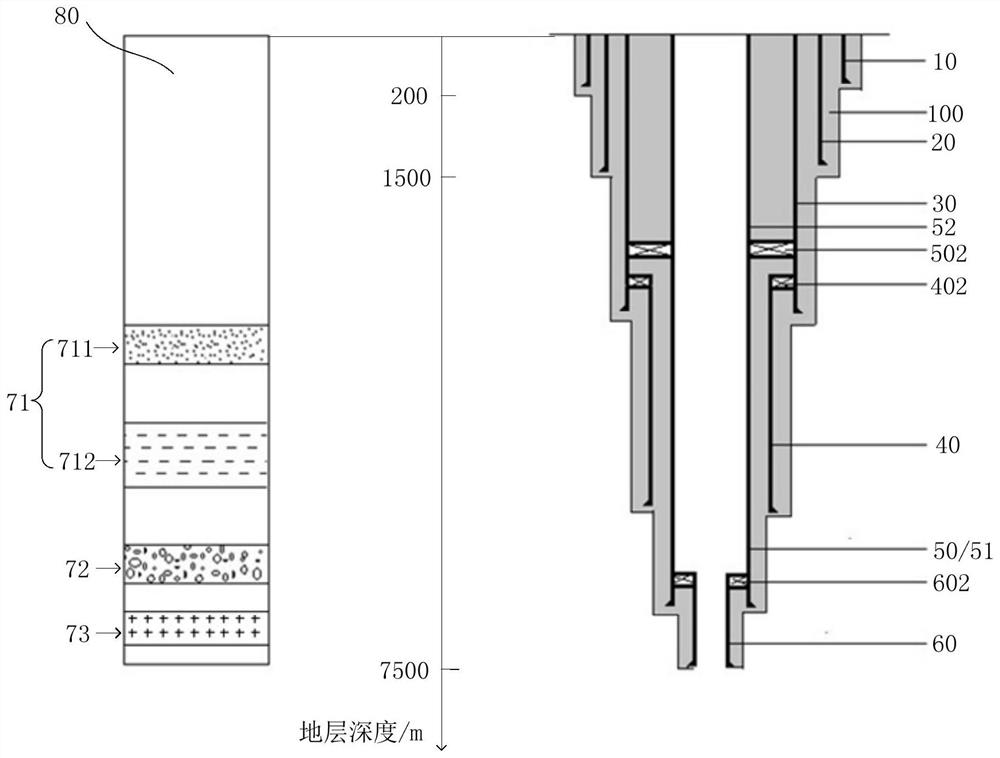

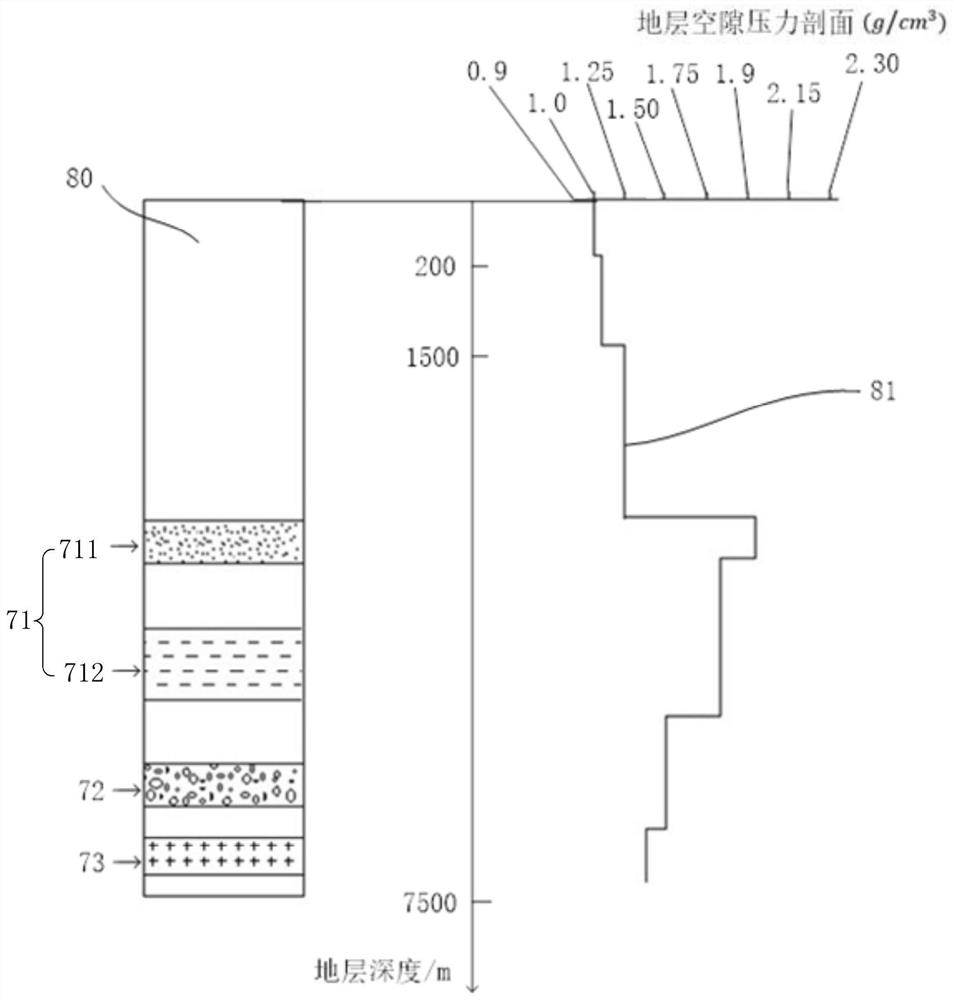

[0058] The present invention provides a method for constructing the shaft structure under the geological conditions with basalt collapse layer 72, such as Figure 2a and image 3 As shown, the construction method includes: step S10, drilling the first well section 101, running the first casing string 10, and cementing; step S20, drilling the second well section 201, running the second Drilling casing string 20, cementing; step S30, drilling third drilling section 301, drilling third drilling section 301 to the upper part of high-pressure layer 71, lowering third casing string 30, cementing; Step S40, drilling the fourth well section 401, the fourth well section 401 drills through the high-pressure layer 71, and drills to the upper part of the basalt collapse layer 72, runs the fourth casing string 40, and cements the well; S50, drill the fifth well section 501, the fifth well section 501 drills through the collapsed basalt layer 72, and drills to the upper part of the oil and...

Embodiment 2

[0078] The present invention provides a well structure under geological conditions with basalt collapse layer 72, such as figure 1 and Figure 2a As shown, the wellbore structure includes: a first casing string 10, a second casing string 20, a third casing string 30, a fourth casing string 40, and a fifth casing string. The pipe string 50 and the sixth tailpipe string 60; run the second casing string 20 from the first casing string 10; run the third casing string 30 to the top of the high-voltage layer 71; The fourth casing string 40 runs through the high-pressure layer 71, and goes down to the upper part of the basalt collapsed layer 72, the fourth casing string isolates the high-pressure layer; the fifth casing string 50 penetrates the basalt collapsed layer 72, and Run into the upper part of the oil and gas target layer 73, the fifth casing string seals off the basalt collapse layer; the sixth liner string 60 is run into the oil and gas target layer 73.

[0079] In this c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com