Movable vibration exciter for simulating train load and loading method thereof

A kind of train simulation, mobile technology, applied in the field of mobile vibration exciter and its loading, can solve the problems of low fidelity and difficult loading, and achieve the effect of wide application prospect and strong expansibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

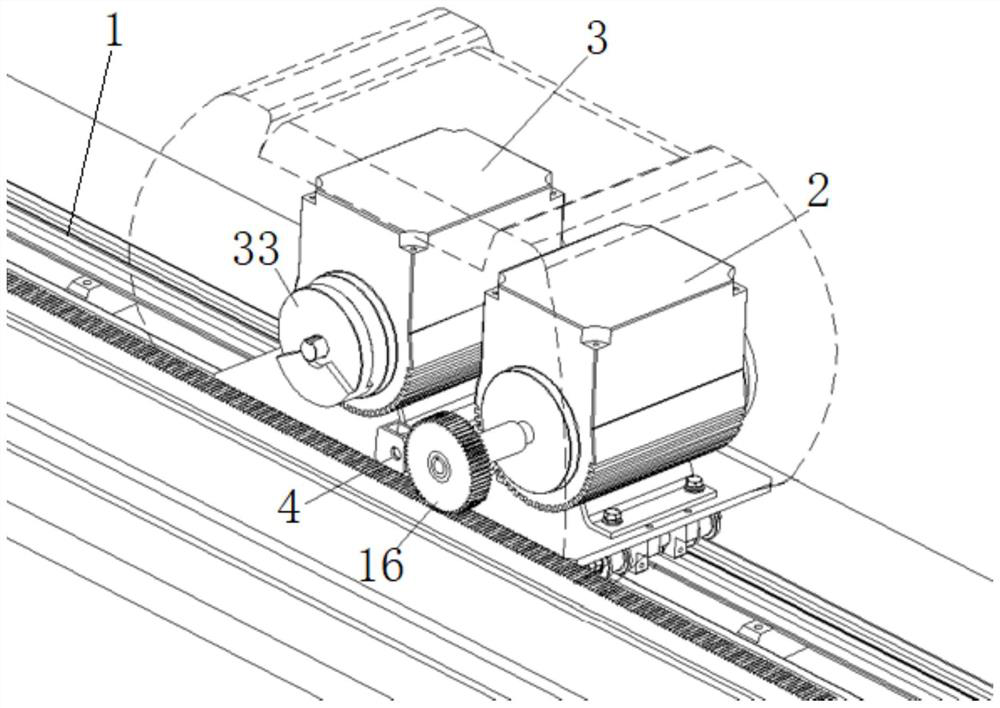

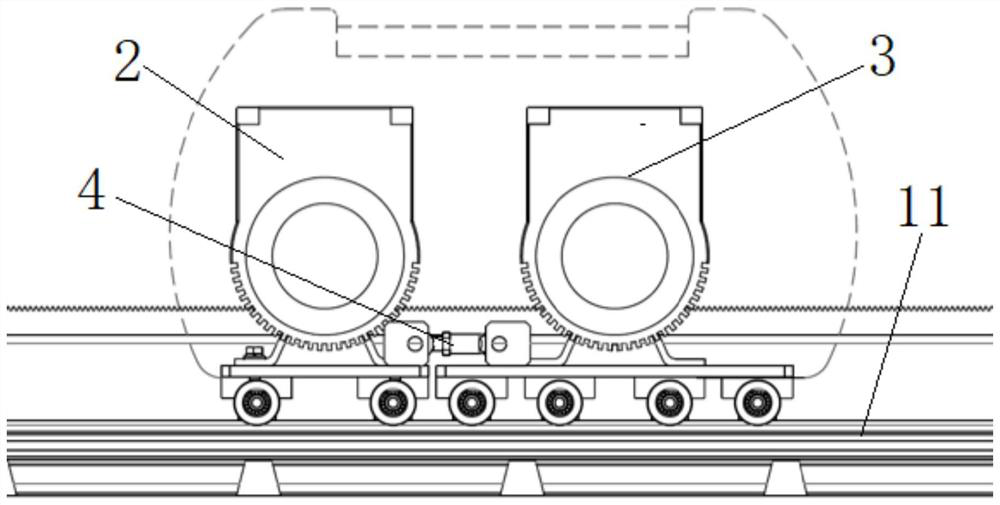

[0050] This embodiment provides a mobile vibrator for simulating train loads, including a track mechanism and a mobile load loading device, the mobile load loading device includes a traction device, a vibrating device and a hinge connection block, and the traction device and the vibrating device pass through the hinge The connecting blocks are connected together, and the traction device plays a traction role on the vibrating device to achieve the effect of linkage.

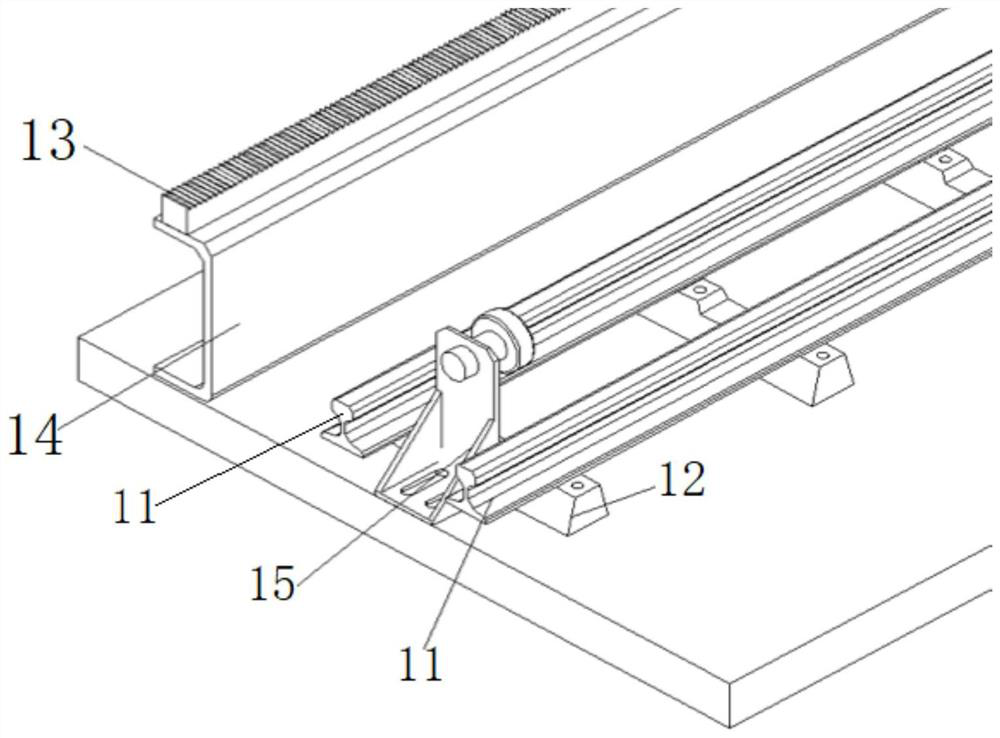

[0051] The track mechanism includes two guide rails, several sleepers, horizontal racks, channel steel, limiters and transmission gears. The two guide rails are arranged horizontally and parallel, and several sleepers are evenly arranged under the guide rails. The guide rails are fixed on the roadbed through the sleepers; Pressure cells and acceleration sensors are pre-embedded in the subgrade, wherein the pressure cells are buried in the soil at the lower part of the subgrade, with a depth of about 1m, arranged lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com