Bottom mud sampling device and method

A technology of sampling device and sediment, applied in the direction of sampling device, etc., can solve the problem of lack of sediment retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

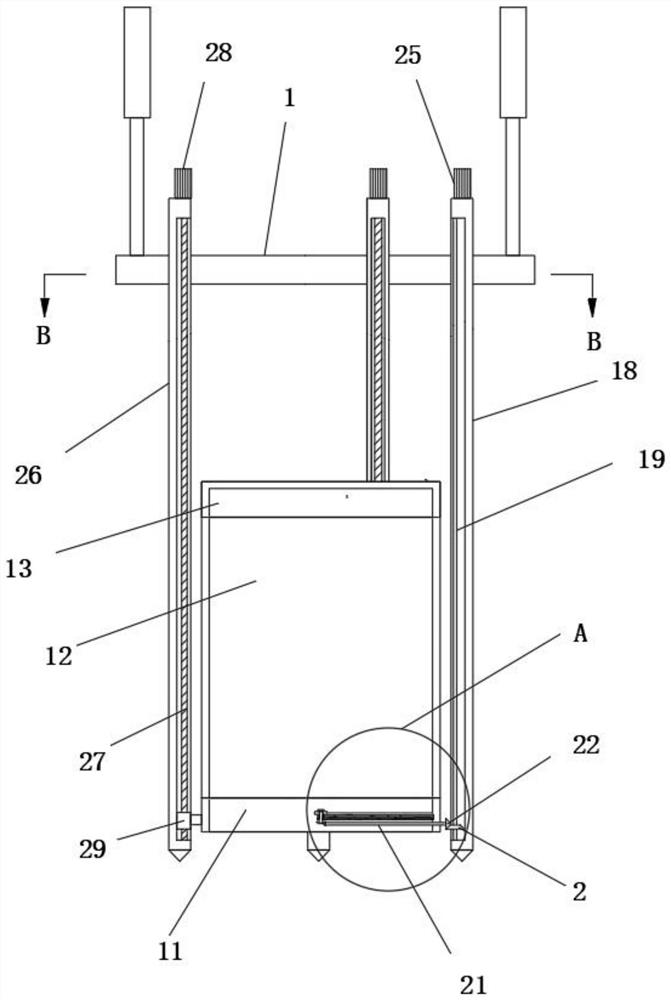

[0050] A bottom mud sampling method, is characterized in that, comprises the following steps

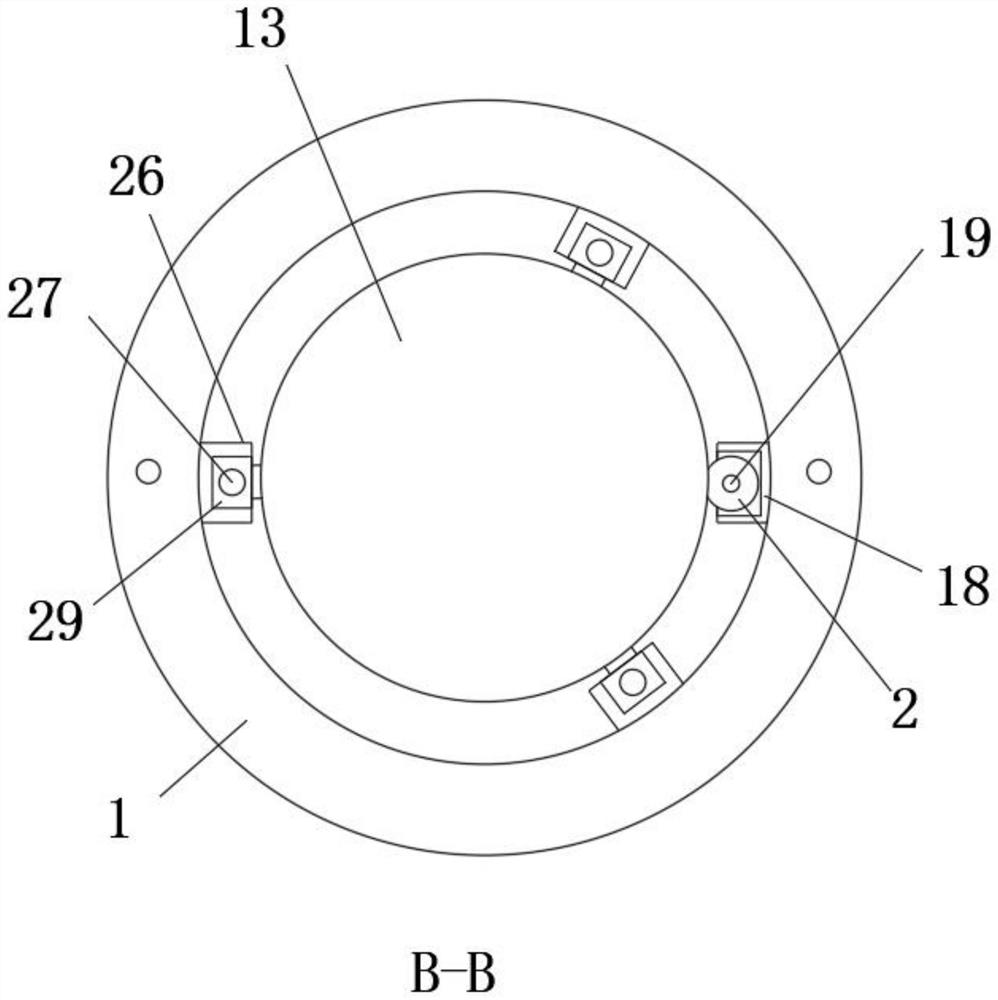

[0051] S1: Separate the storage cylinder, the bottom ring and the top cover, and ensure that they are all on the coaxial vertical axis;

[0052] S2: Insert the overall sampling device into the sediment under the action of the lifting mechanism, and ensure that the storage tank is completely submerged;

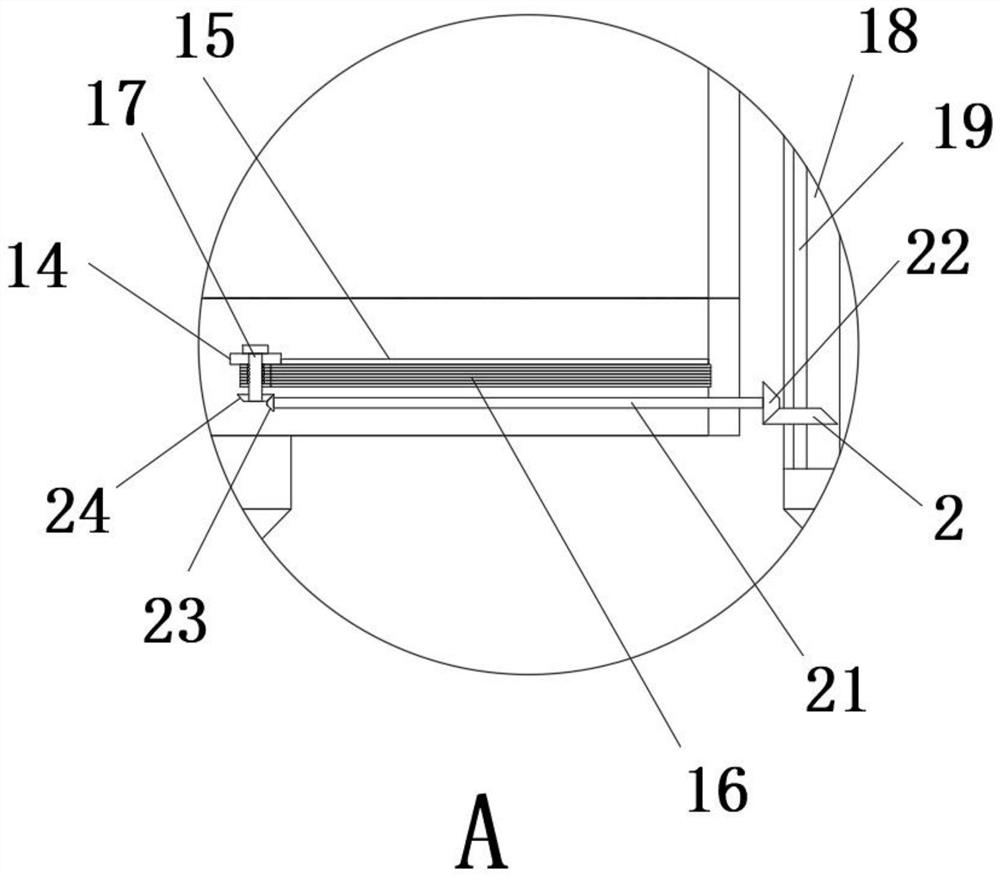

[0053] S3: The height adjustment mechanism drives the bottom ring, the storage cylinder and the top cover to realize closure;

[0054] S4: The opening and closing device closes the baffle in the bottom ring to complete the overall seal between the bottom ring, the storage cylinder and the top cover;

[0055] S5: The height adjustment mechanism and the lifting mechanism cooperate to lift the three out of the liquid surface synchronously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com