A sensor-adaptive heating method

A heating method and self-adaptive technology, which is applied in the direction of instruments, material electrochemical variables, control/regulation systems, etc., can solve the problems of concentrated heating time, long waiting process, and temperature lag in temperature sensor induction, and achieve stable heating effect and high efficiency. The effect of average consumption, convenient development and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention are further described in detail through specific examples below. It should be understood that the following examples are only used as specific illustrations, and do not limit the scope of the present invention, and at the same time, obvious changes and modifications made by those skilled in the art according to the present invention are also included in the scope of the present invention.

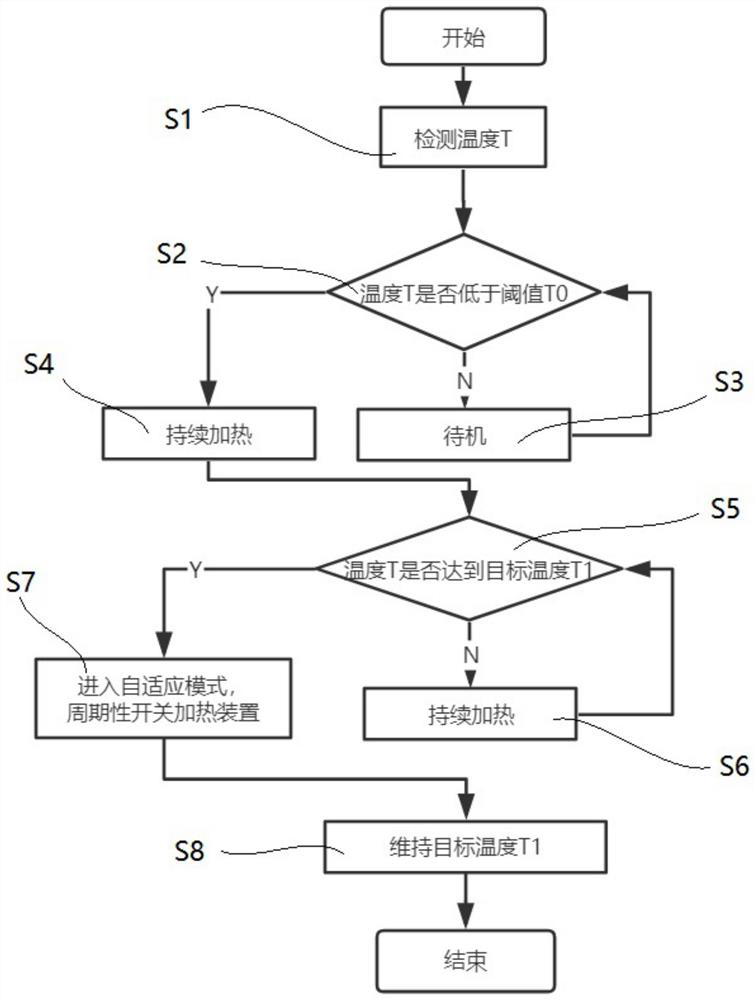

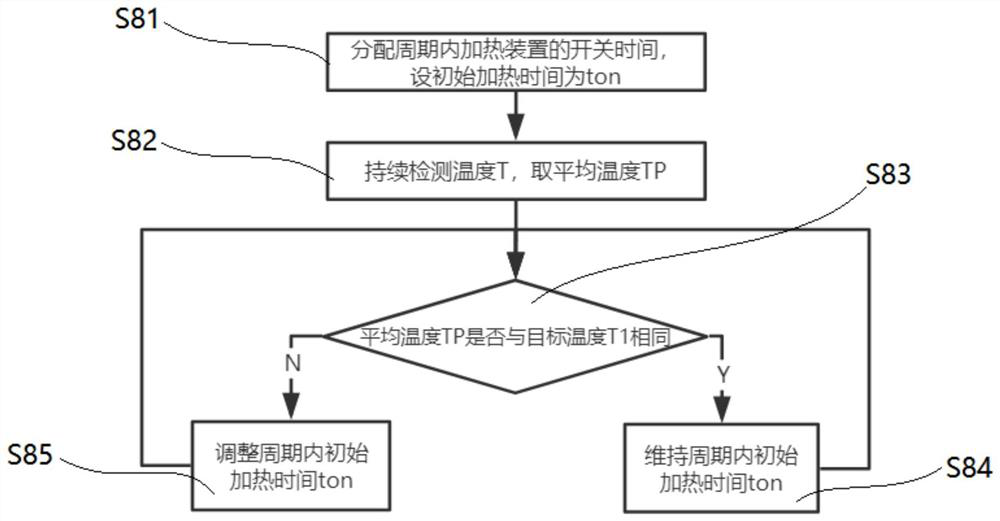

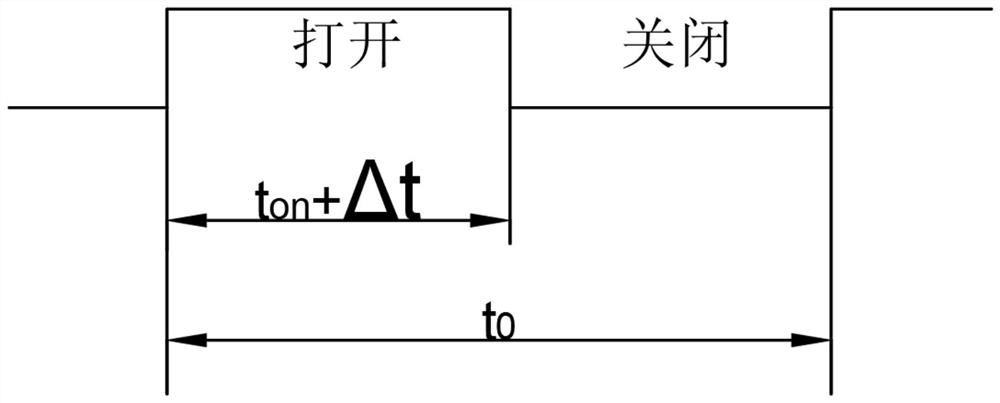

[0040] Such as Figure 1-3 As shown, a sensor-adaptive heating method is implemented to a heating system, the heating system includes a controller, a heating device, a temperature sensor and a timer, and the sensor-adaptive heating method includes the following steps:

[0041] S1, the temperature sensor detects the temperature T;

[0042] S2. If the temperature T is higher than the heating threshold T 0 Then execute step S3, if the temperature T is lower than the heating threshold T 0 Then execute step S4;

[0043] S3, enter the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com