Method for analyzing online period of fan-shaped section guide roller of continuous casting machine based on finite elements

A continuous casting machine segment and finite element technology, applied in computer-aided design, special data processing applications, instruments, etc., can solve the problems of unavailable data distribution and high experiment cost, so as to improve calculation efficiency and accuracy, and improve production Efficiency, the effect of avoiding computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0050] The simulation method of the present invention will be further described below in conjunction with embodiments and drawings:

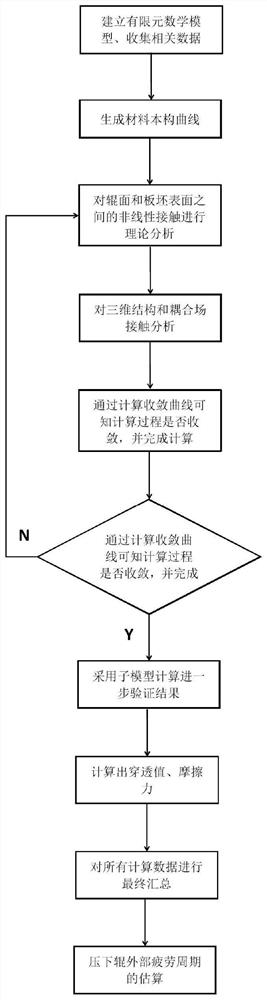

[0051] The present invention is a method based on the finite element analysis of the on-line cycle of the segment guide roller of a continuous caster. The embodiment includes the following steps:

[0052] 1. Problem description and related parameter boundary condition setting

[0053] a. Basic parameters

[0054] According to the provided materials and relevant data of the pressing roller, see Table 1-1.

[0055] Table 1-1 Slab and reduction roll parameters

[0056]

[0057] b. Slab issues and material parameters

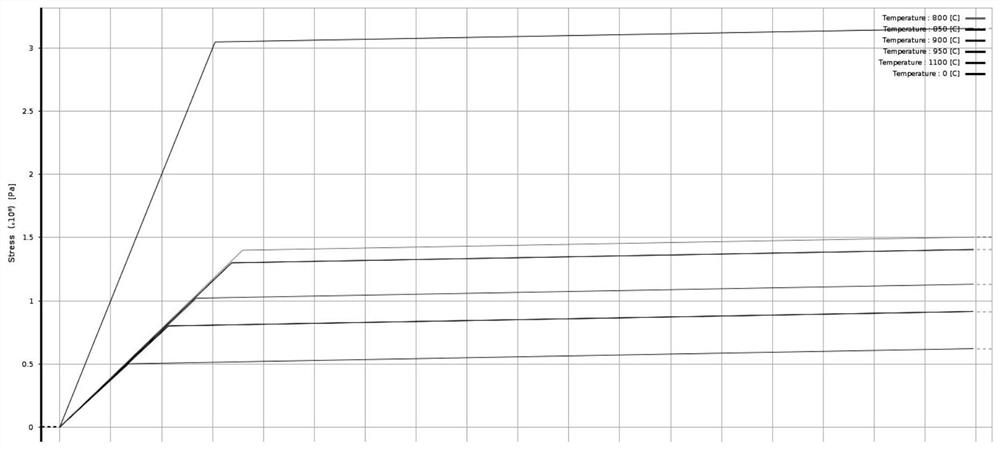

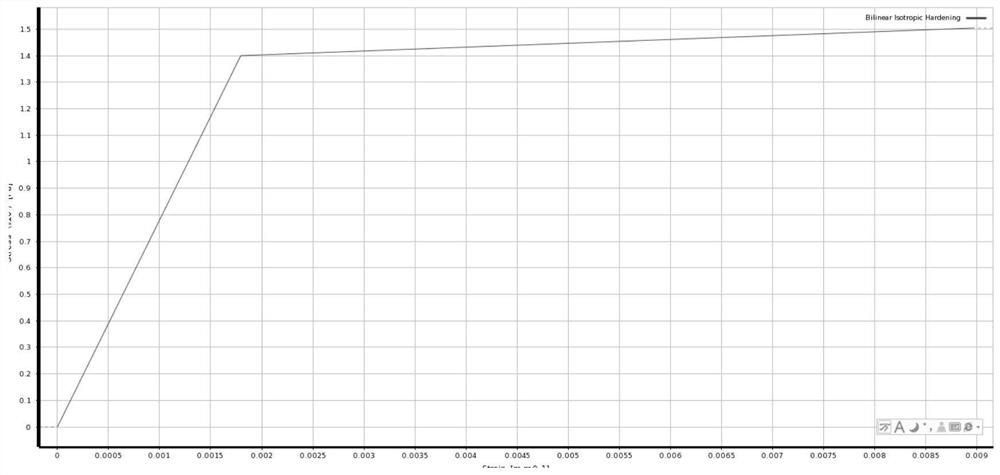

[0058] In the process of metal deformation at high temperature, the dynamic behavior of the material will have a significant impact, see figure 2 As shown, in order to simplify the material constitutive curve, a bilinear material is used to simulate the material constitutive curve.

[0059] c. In this calculation, the material's constitutive curv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap