Chamfering device for circuit board production

A technology of chamfering device and circuit board, which is applied in the direction of circuit board tool positioning, printed circuit, printed circuit manufacturing, etc., can solve problems such as poor fixing stability of the board, and achieve the effects of ensuring stability, reducing friction and improving fluency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

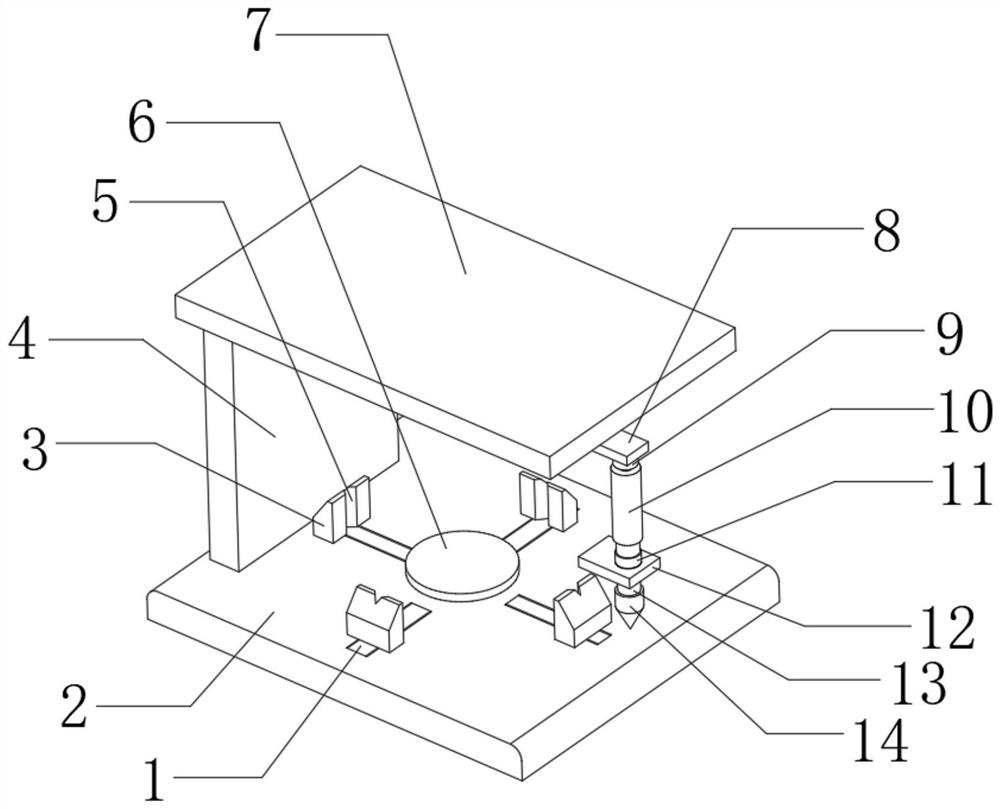

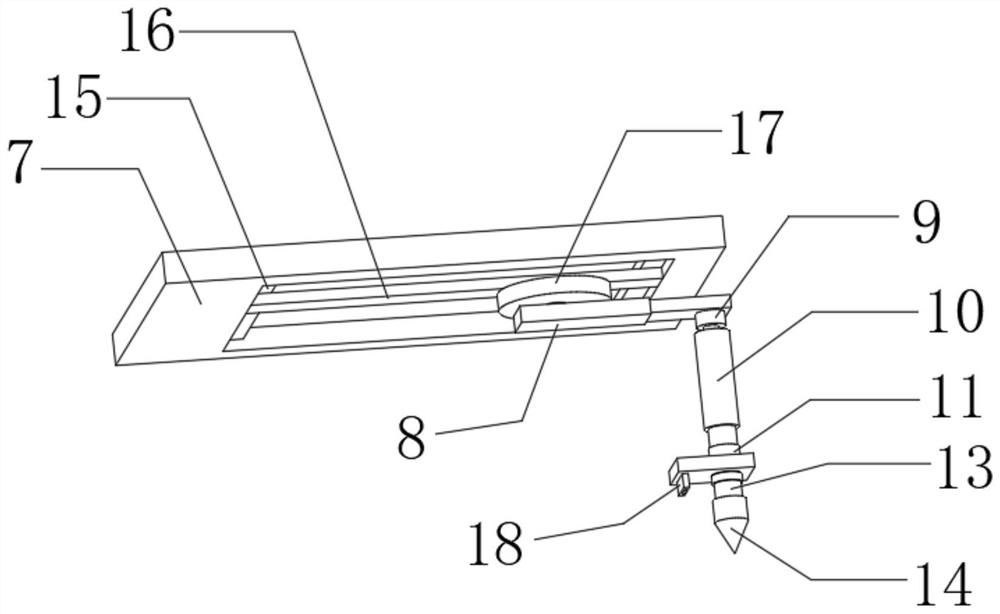

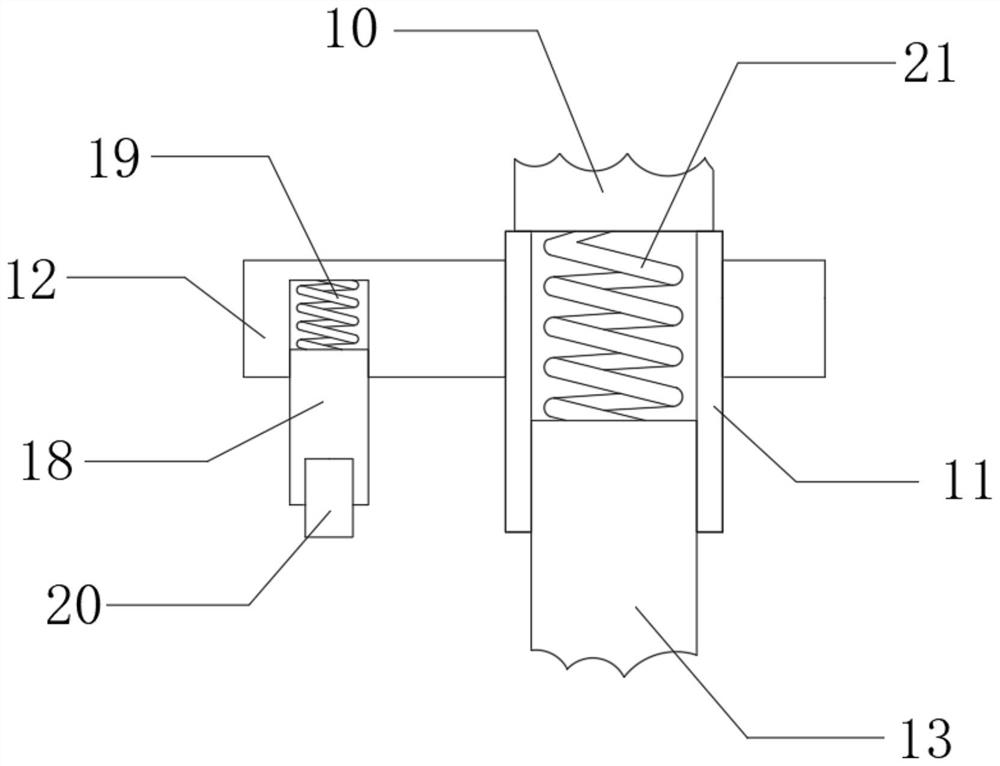

[0027] Reference Figure 1-4 , A chamfering device for circuit board production, comprising a supporting base 2. The outer wall on the top side of the supporting base 2 is connected with a first supporting plate 4 by bolts, and the top outer wall of the first supporting plate 4 is connected with a supporting top plate 7 by bolts , The bottom outer wall of the support top plate 7 is provided with a first groove, and the inner walls on both sides of the top of the first groove are connected with a second electric guide rail 15 through bolts, and the bottom outer walls of the two second electric guide rails 15 are slidably connected with a second Electric slider, and the bottom outer walls of the two second electric sliders are connected by bolts to the same third electric rail 16, and the bottom outer wall of the third electric rail 16 is slidably connected with the third electric slider. The bottom outer wall is connected with a mounting plate 17 through bolts, the bottom central...

Embodiment 2

[0036] Reference Figure 1-5 , A chamfering device for circuit board production, further comprising an air duct 25 whose casing bolts are installed on one side of the outer wall of the first support plate 4, and one side of the outer wall of the air duct 25 is bolted to an air pump 24, and one end of the air duct 25 The outer wall of the air guide tube 26 is connected with an air guide tube 26 by bolts, and the outer wall of one end of the air guide tube 26 is connected with a jet head 27 by bolts, and the other end of the inner wall of the air guide tube 25 is connected with a filter screen 23 by bolts.

[0037] Working principle: After the device is used, the air guide tube 25, the air hose 26, the jet head 27 and the air pump 24 can be set to blow air from the air pump to the jet head. This improves the convenience of device cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com