Fire fighting hose achieving automatic cleaning and coiling

A fire hose and automatic cleaning technology, which is applied in fire rescue and other directions, can solve the problems of increasing the labor intensity of the staff and wasting the rewinding efficiency of the fire hose, and achieve the goals of reducing labor intensity, improving stability, and improving cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

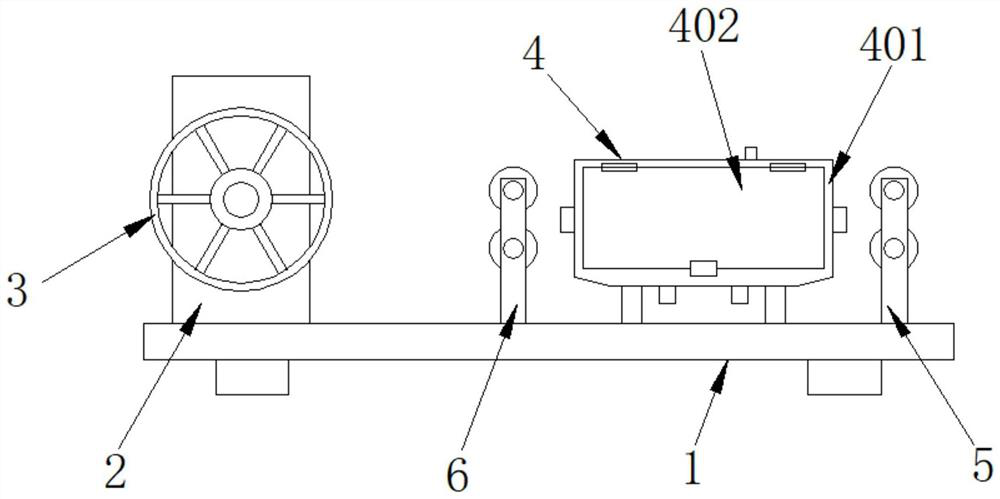

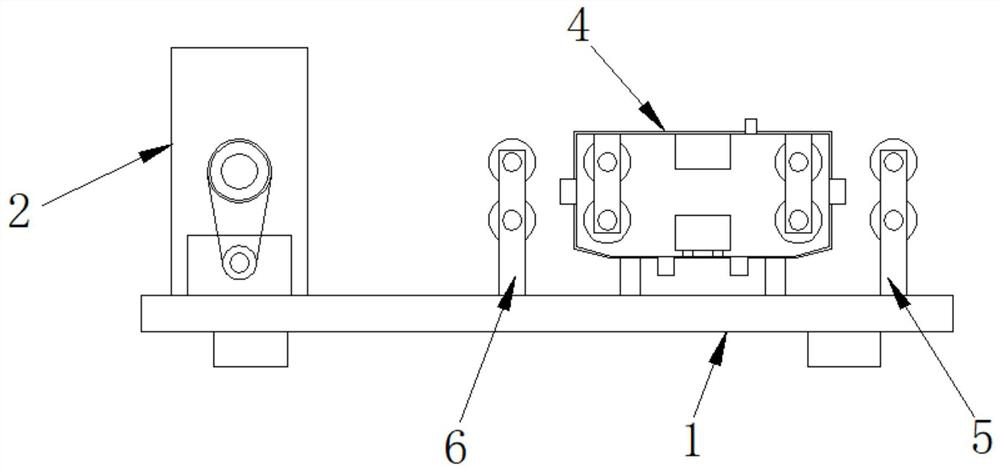

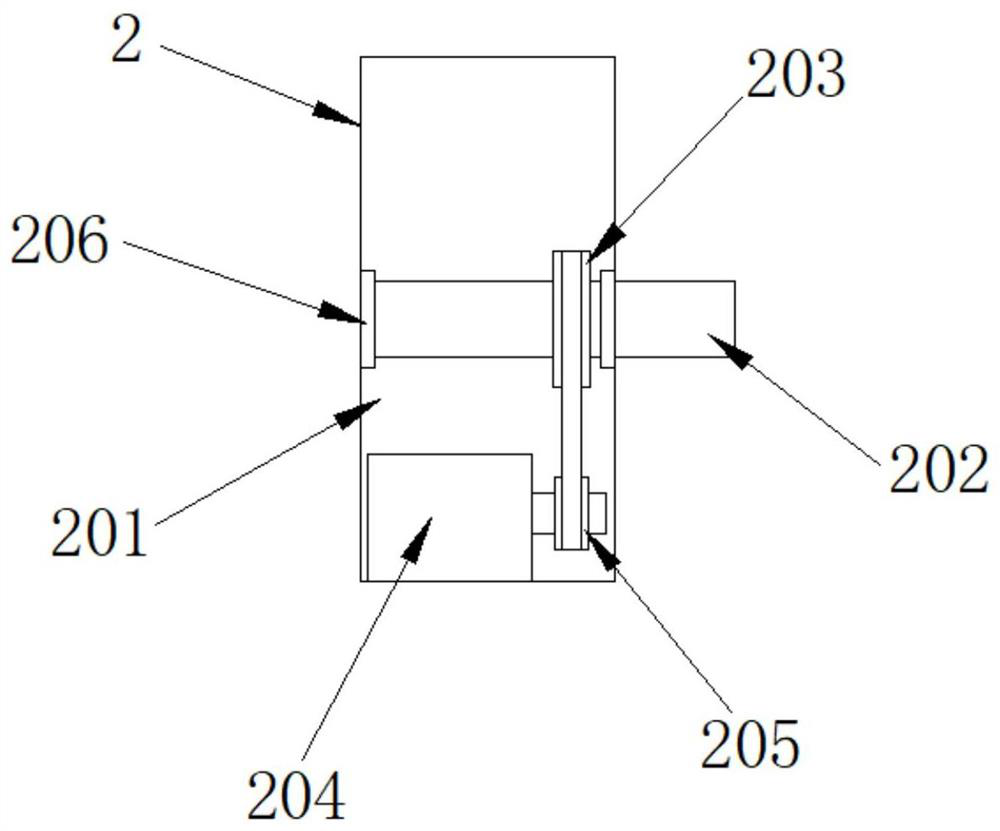

[0022] Such as Figure 1-5 As shown, the present invention provides a technical solution: a fire hose device for automatic cleaning and winding, including a base 1, a drive mechanism 2 is installed on one side of the top surface of the base 1, and the drive mechanism 2 is provided by a protective box 201, a winding shaft 202, a driven wheel 203, a motor 204, a driving wheel 205 and a bearing 206, the output end of the winding shaft 202 is disassembled and connected with a winding reel 3, and the other side of the top surface of the base 1 is equipped with a cleaning mechanism 4 , the cleaning mechanism 4 is composed of a cleaning box 401, a box door 402, a material guide pipe 403, a first conveying roller 404, a gantry frame 405, a high-pressure nozzle 406, a water inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com