Portable device for trimming local high point of internal thread

A portable device and local high-point technology, which is applied in the field of portable devices for local high-point trimming of internal threads, can solve the problems of shortening product life, increasing maintenance and use costs, and high flexibility requirements for ectopic drilling, achieving high-precision repeatability Trimming, easier control of thread profile and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

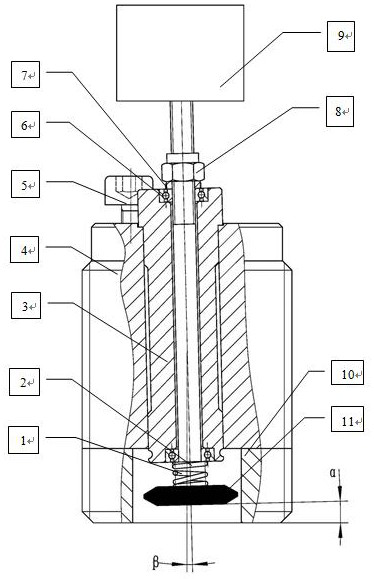

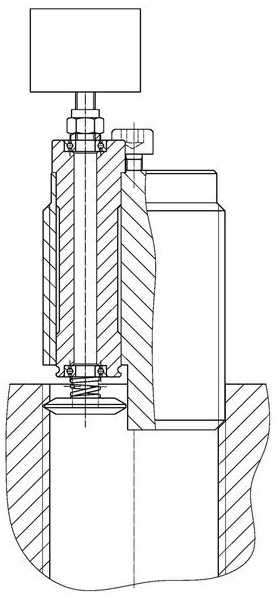

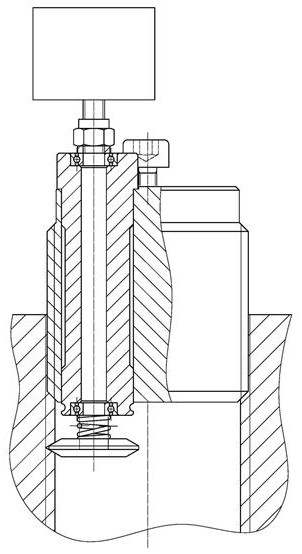

[0023] Example: such as figure 1 As shown, the present invention is a portable device for trimming local high points of internal threads, which is mainly composed of a rotating shaft 1, a spring 2, an eccentric sleeve 3, a threaded shaft 4, an eccentric screw 5, a bearing 6, a washer 7, and a lock nut 8 , an air motor 9, a detachable threaded shaft 10, and a grinding wheel 11. The grinding wheel 11 is installed on the rotating shaft 1, the spring 2 is set on the rotating shaft, the bearings 6 are installed at both ends of the eccentric sleeve 3, the assembled rotating shaft 1 passes through the eccentric sleeve 3, and the washer 7 and the lock nut 8 are used to lock, Pass the above-mentioned whole through the threaded shaft 4, lock it with the eccentric screw 5, install the detachable threaded shaft 10 on the threaded shaft 4, and install the air motor 9 on the rotating shaft 1. The device is screwed into the internal thread to be trimmed through the threaded shaft 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com