Drill rod forward and reverse rotation connecting device for underground coal mine drilling machine

A connection device, forward and reverse technology, applied to drill pipes, key connections, connecting components, etc., can solve the problems of affecting the progress of the project, scrapped drilling, stuck drill bits or drill pipes, etc., to achieve safe and convenient handling, guarantee The effect of safe construction and project progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

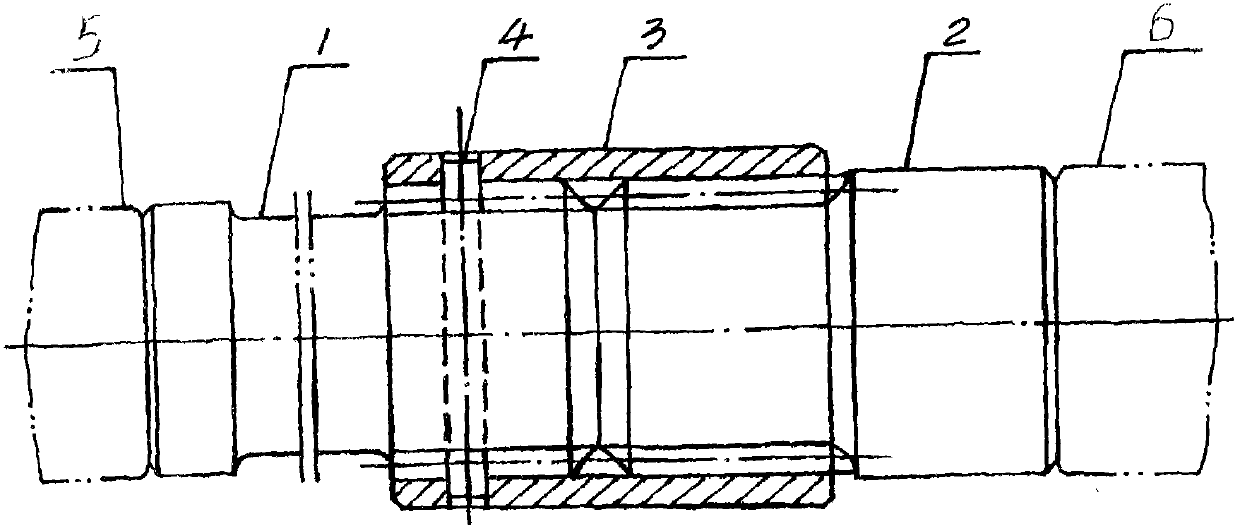

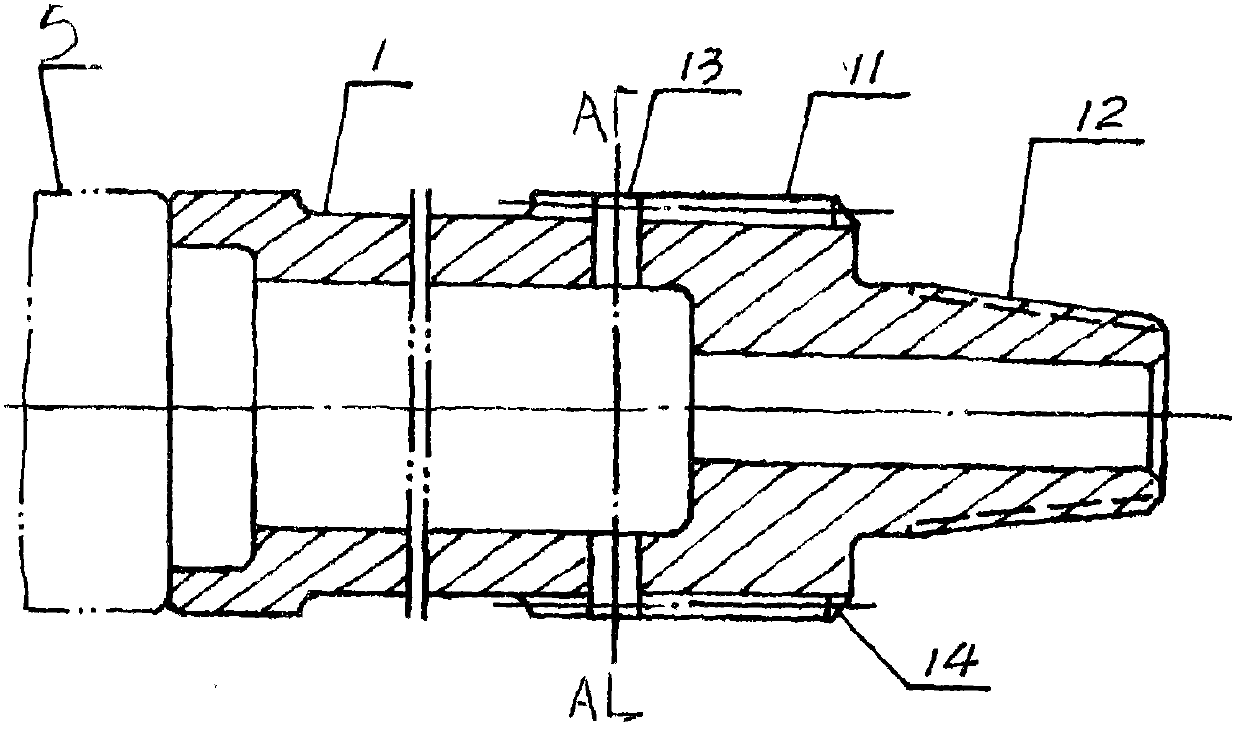

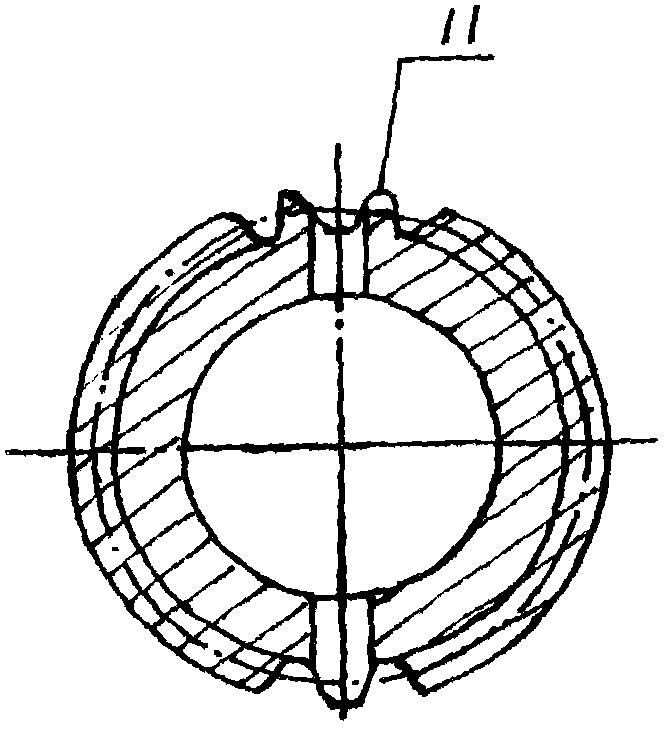

[0014] Such as Figure 1-8 As shown, a forward and reverse connection device for drill rods used in underground drilling rigs in coal mines is composed of first and second outer splines, inner spline sleeves and spring cylindrical pins. The outer walls of the first and second outer splines 1, 2 are provided with involute outer splines 11, 21, and the inner cavity of the inner spline sleeve 3 is processed with involute inner splines 31 throughout the axial length. The involute outer splines 11 and 21 of the first and second outer splines are fitted in the inner cavity of the inner spline sleeve 3 and processed with an involute inner spline 31 throughout the axial length, the first outer spline One end of the drill is connected to the drill 5 rod, and the other end is provided with a conical male thread 12, which is matched and connected with the conical female thread 22 provided in the cavity at one end of the second external spline 2. The involute outer spline 11 of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com