Equipment and method for filling cigarette carton with cigarette cases

A technology for a carton and a cigarette case, which is applied in the field of tobacco packaging, can solve the problems of low production efficiency, high labor intensity of workers, and inability to implement a cartoning machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

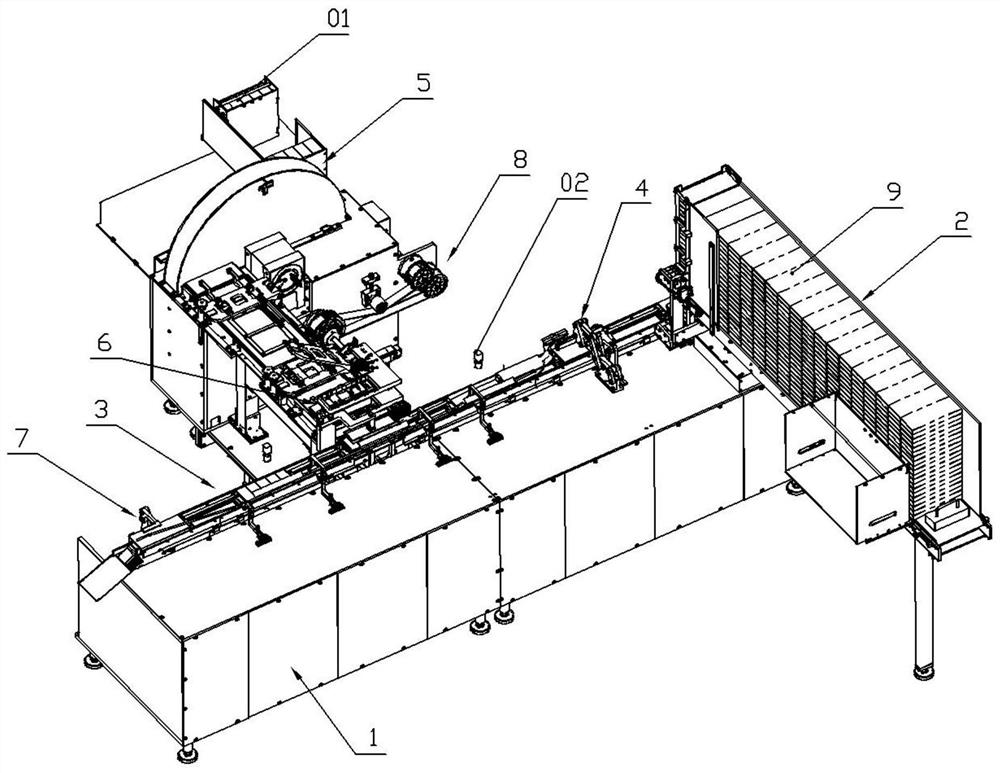

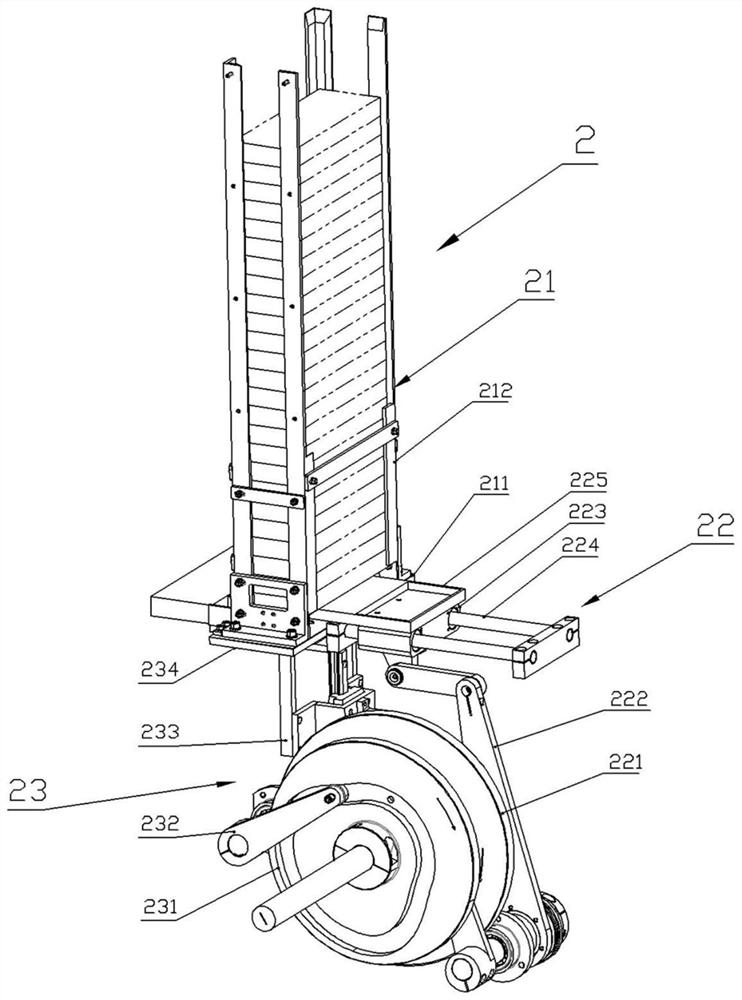

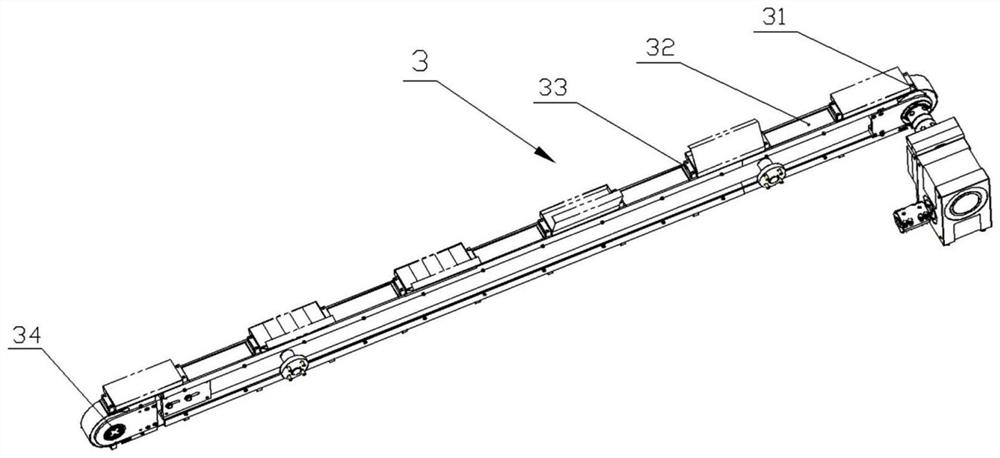

[0063] like figure 1 As shown, the equipment for filling cartons of cigarettes disclosed in this embodiment includes a frame 1, a box lowering device 2, a box transporting device 3, a box opening device 4, a cigarette box turning mechanism 5, and a box filling mechanism. Device 6, closing cover device 7 and driving device 8.

[0064] The frame 1 is a rectangular frame, and a plurality of legs are arranged at the bottom thereof. The lower box device 2 stands on the foundation and is located at one end of the frame in the length direction, the box transport device 3 is arranged on the frame along the length direction, the box opening device 4, the box filling device 6, and the lid closing device 7 are along the box transport direction Arranged on the frame in turn, located above the box transporting device; the cigarette box turning mechanism 5 is arranged outside the box filling device to ensure that the front side of the cigarette box is input. The driving device is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com