Corrugated paper packaging box

A packaging box and corrugated paper technology, applied in the field of corrugated paper packaging boxes, can solve problems such as damage and scratches left on the packaging box, and achieve the effect of safe and convenient use, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

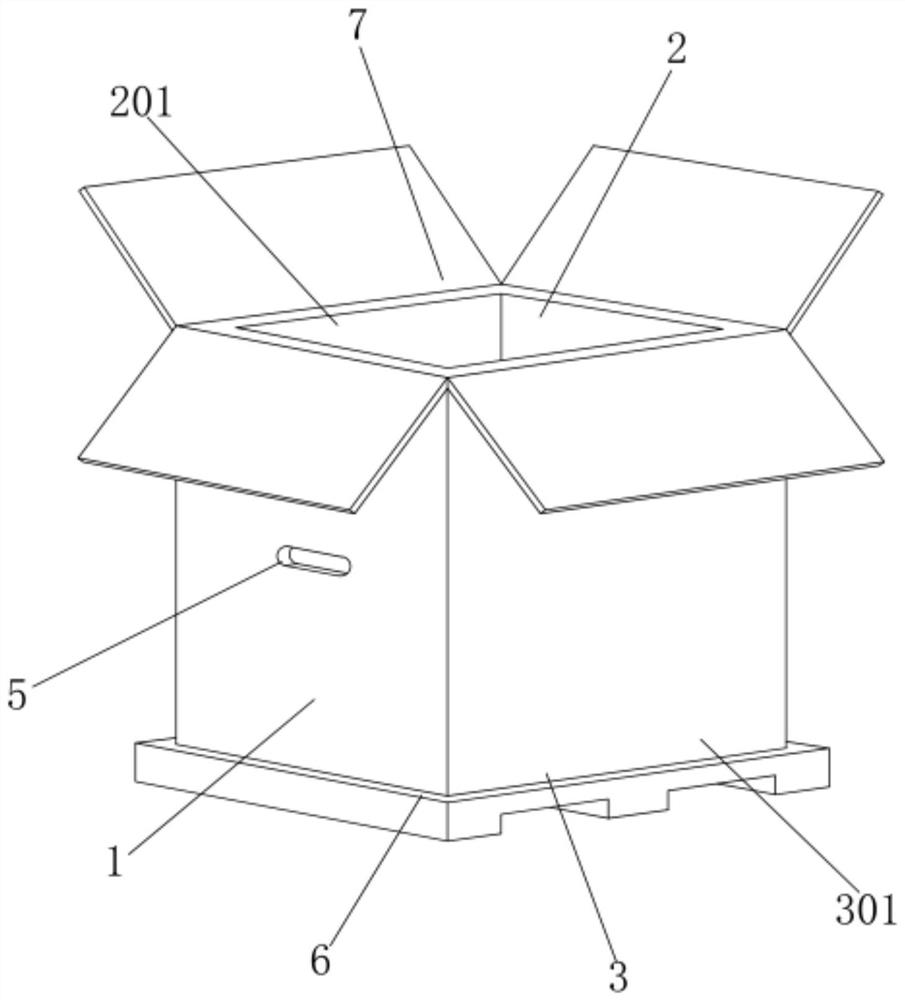

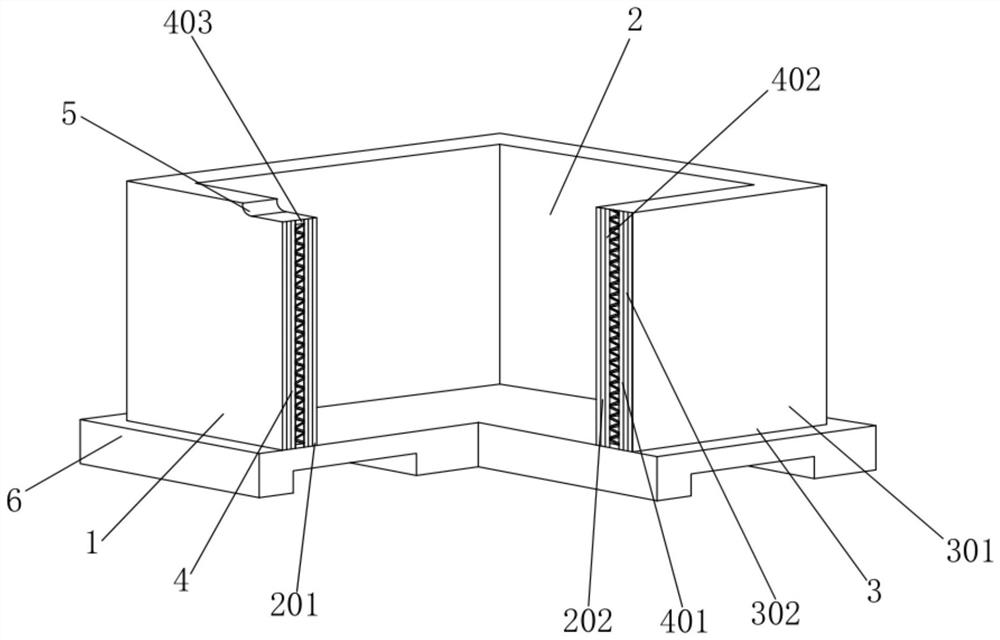

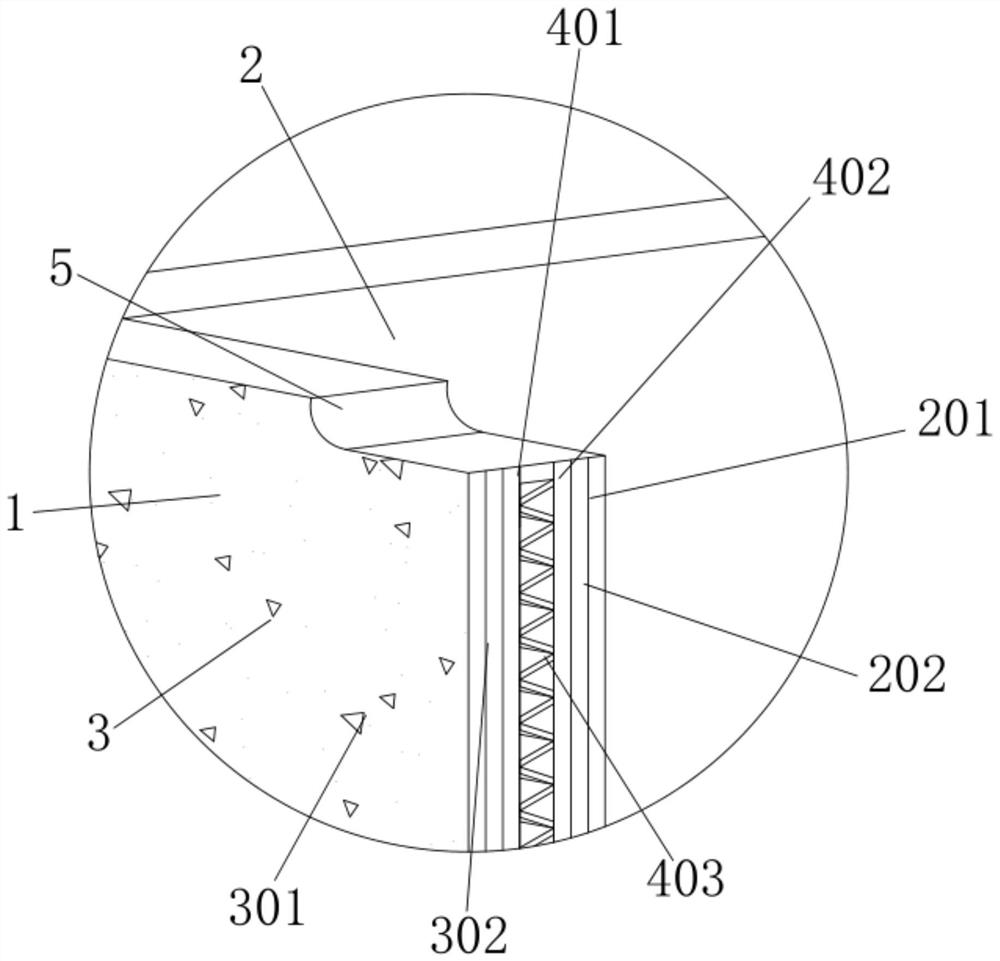

[0036] A corrugated packaging box, comprising a box body 1 and a box cover 7, the four sides of the upper end of the box body 1 are rotatably connected with the box cover 7 through creases, the box cover 7 can be rotated and connected above the box body 1, the box body 1 and The inner center of the box cover 7 is formed by a central corrugated assembly 4, and the central corrugated assembly 4 includes an outer cardboard 401, an inner cardboard 402 and a corrugated layer 403. The corrugated layer 403 is located at the inner center of the box body 1 and the box cover 7. The inner side is fixedly connected with the inner cardboard 402, and the corrugated layer 403 is used to provide the supporting capacity of the box body 1. The outer side of the corrugated layer 403 is fixedly connected with the outer cardboard 401. The thickness of the inner cardboard 402 and the outer cardboard 401 are consistent. The ply 403 is in the shape of a V-shaped corrugated ply cardboard.

Embodiment 2

[0038] As an option, see figure 1 , 2 , 3, 4 and 6, corrugated cardboard packaging box, the outer outer wall of box body 1 and box cover 7 is made of outer component 3, and outer component 3 comprises wear-resistant coating 301 and waterproof coating 302, and wear-resistant coating 301 and waterproof coating Layer 302 is distributed sequentially from the outside to the inside on the outside of the outside cardboard 401, the waterproof coating 302 is coated on the outside of the outer wall of the outside cardboard 401, the wear-resistant coating 301 is coated on the outside of the outer wall of the waterproof coating 302, the wear-resistant coating 301 and the waterproof The coating thickness of the coating 302 is roughly the same. The wear-resistant coating 301 is a wear-resistant ceramic coating, which is a powdery ceramic made of acid-resistant and resistant artificial synthetic raw materials through strict process ratio and advanced inorganic polymerization technology. Mat...

Embodiment 3

[0041] As an option, see figure 1 , 3, 4, 5 and 6, corrugated packaging box, the inner wall of the inner side of the box body 1 and the box cover 7 is composed of an inner component 2, the inner component 2 includes an antibacterial coating 201 and a thermal insulation coating 202, and the antibacterial coating 201 and the thermal insulation coating 202 The inside of the inner cardboard 402 is distributed sequentially from the inside to the outside, the thermal insulation coating 202 is coated on the inner inner wall of the inner cardboard 402, the antibacterial coating 201 is coated on the inner inner wall of the thermal insulation coating 202, the antibacterial coating 201 and the thermal insulation coating The coating thickness of 202 is the same. The antibacterial coating 201 is made of nano-silver paint. During the production process of the paint, nanoparticles are added as an anti-bacterial component. When the nano-silver enters the bacteria and combines with oxygen meta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap