Preparation of electrode material based on bird manure

A technology of electrode material and guano, which is applied in the field of preparation of electrode materials, can solve the problems of inability to utilize carbon elements, plants cannot absorb carbon elements, etc., and achieve good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

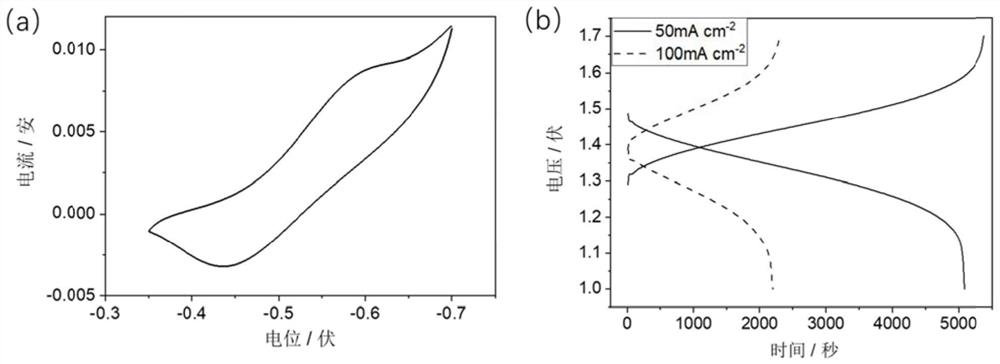

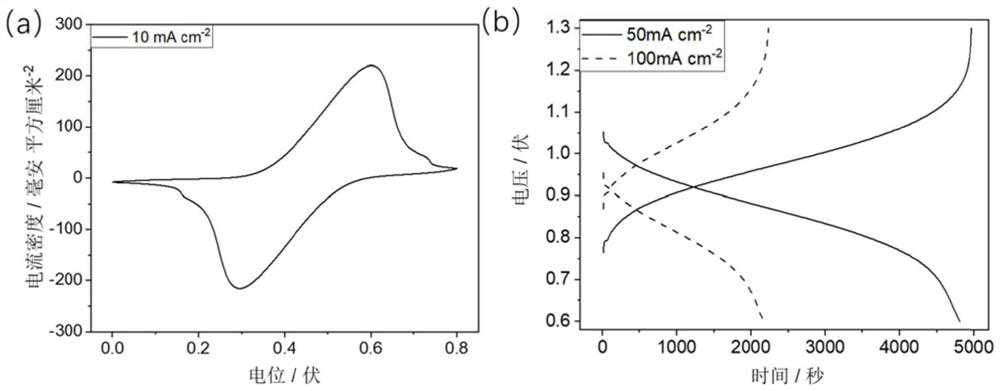

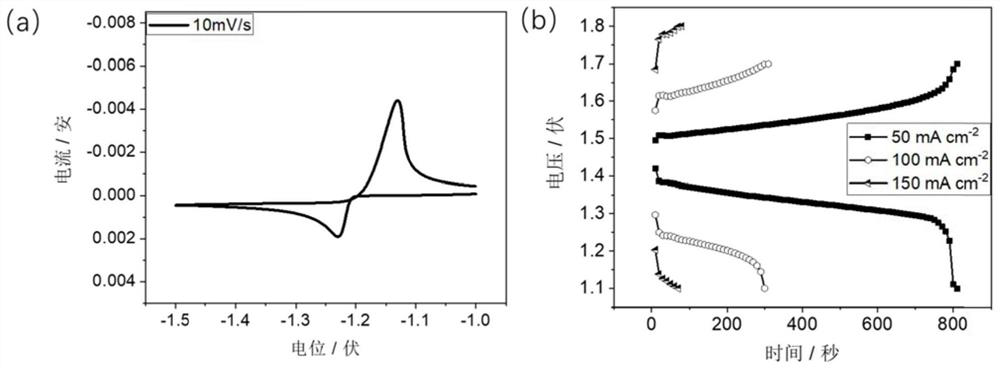

Image

Examples

Embodiment 1

[0028] A preparation of guano-based electrode material, comprising the following steps:

[0029] Step 1: Put 200g of collected guano into 500g of water, and let it settle naturally for 2 hours;

[0030] Step 2. Take out the bottom sediment and dry it at 105°C for later use;

[0031] Step 3, soak the dried sediment in 3mol / L sodium hydroxide solution for 1 hour, then take it out and clean it;

[0032] Step 4, soak the cleaned substance in 3mol / sulfuric acid solution for 1 hour, then take it out and clean it;

[0033] Step 5. Soak the cleaned substance in 3% hydrogen peroxide for 30 minutes, take it out, wash it, and dry it at 105°C;

[0034] Step 6, carbonizing the dried material at 700°C in a nitrogen atmosphere;

[0035] Step 7. After grinding the carbonized powder, disperse it with 5% carbon nanotubes and 5% polyvinylidene fluoride in DMF solvent according to the mass ratio to make electrode paste, coat it on carbon cloth, and dry the solvent , to prepare the electrode. ...

Embodiment 2

[0038] A preparation of guano-based electrode material, comprising the following steps:

[0039] Step 1: Put 300g of collected guano into 500g of water, and let it settle naturally for 2 hours;

[0040] Step 2. Take out the bottom sediment and dry it at 105°C for later use;

[0041] Step 3. After soaking the dried sediment in 3mol / L ammonia solution for 1 hour, take it out and clean it;

[0042] Step 4, soak the cleaned substance in a 5mol / sulfuric acid solution for 1 hour, then take it out and clean it;

[0043] Step 5. Soak the cleaned substance in 3% hydrogen peroxide for 30 minutes, take it out, wash it, and dry it at 105°C;

[0044] Step 6, graphitizing the dried substance at 1800°C in a nitrogen atmosphere;

[0045] Step 7. After grinding the graphitized powder, disperse it with 5% acetylene black and 5% polyvinylidene fluoride in DMF solvent according to the mass ratio to make electrode paste, coat it on carbon cloth, and dry the solvent , to prepare the electrode. ...

Embodiment 3

[0048] A preparation of guano-based electrode material, comprising the following steps:

[0049] Step 1: Put 300g of collected guano into 300g of water, and let it settle naturally for 2 hours;

[0050] Step 2. Take out the bottom sediment and dry it at 105°C for later use;

[0051] Step 3. After soaking the dried sediment in 6mol / L sodium hydroxide solution for 1 hour, take it out and clean it;

[0052] Step 4, soak the cleaned substance in 6mol / sulfuric acid solution for 1 hour, take it out and clean it;

[0053] Step 5. Soak the cleaned substance in 6% hydrogen peroxide for 30 minutes, take it out, wash it, and dry it at 105°C;

[0054] Step 6, carbonizing the dried material at 800°C in a helium atmosphere;

[0055] Step 7. After grinding the carbonized powder, disperse it with 5% carbon nanotubes and 5% polytetrafluoroethylene polyvinylidene fluoride in DMF solvent according to the mass ratio to make an electrode paste, and coat it on the carbon cloth , and dry the sol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap