Unit bathroom splicing type bottom plate

An integral and bottom plate technology, applied in the bathroom field, can solve problems such as reducing the anti-skid effect, and achieve the effect of preventing loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

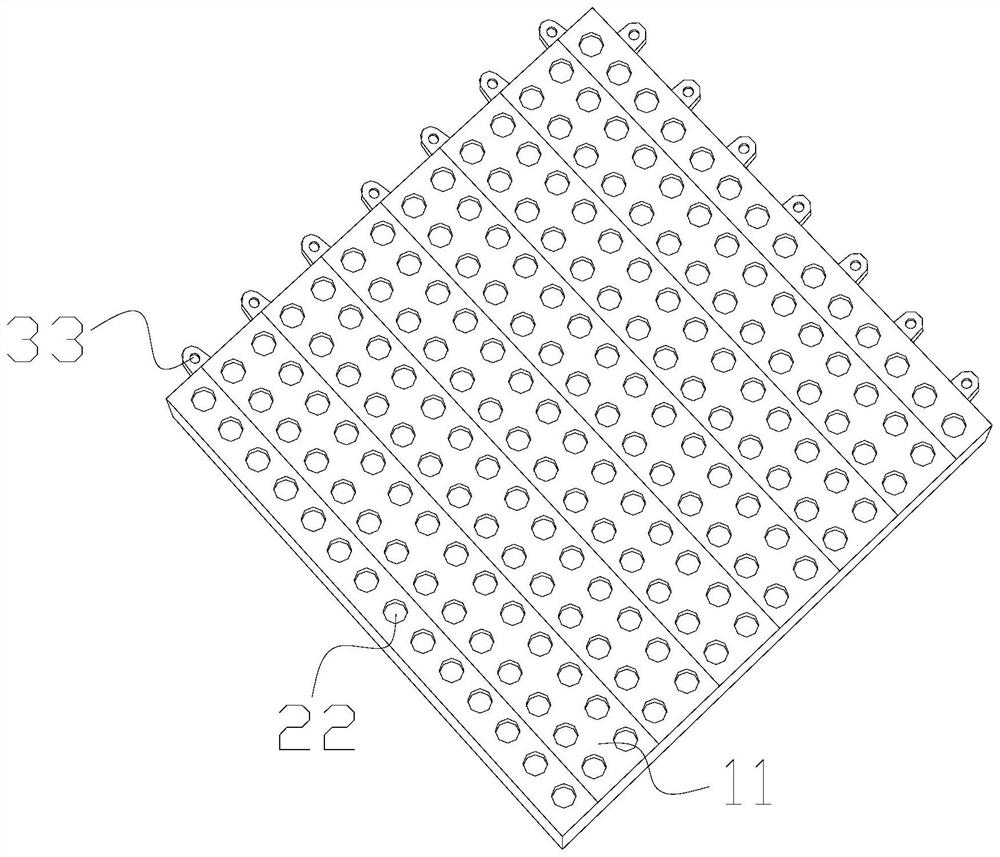

[0032] as attached figure 1 to attach Image 6 Shown:

[0033] The present invention provides an integral bathroom splicing floor, the structure of which includes a main panel 11, a port 22, and a buckle 33, the port 22 and the main panel 11 are an integrated structure, and the buckle 33 is fixed Jigsaw 11 outer surfaces.

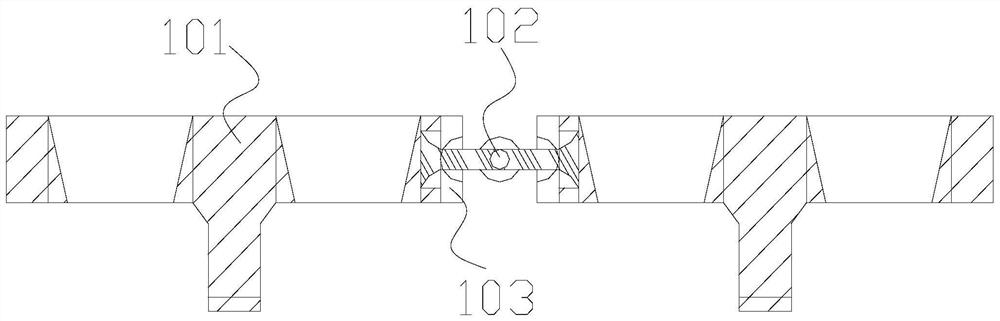

[0034] The main panel 11 includes a strut 101 , a pulling core 102 , and a joint 103 , the joint 103 and the strut 101 are an integrated structure, and the pulling core 102 penetrates between the joints 103 .

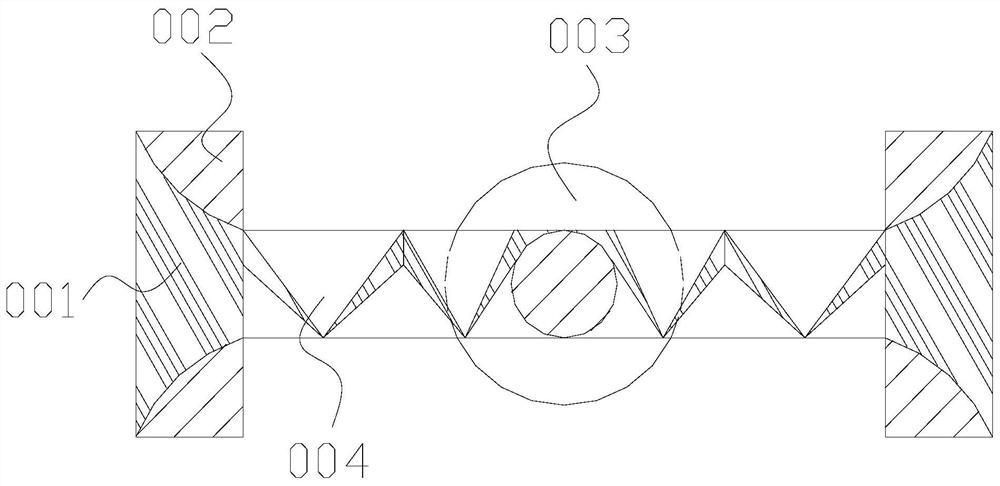

[0035] Wherein, the pulling core 102 includes a solid head 001, an outer solid block 002, a middle ball 003, and a brace 004, the solid head 001 is fixed between two outer solid blocks 002, and the brace 004 is installed on the solid head 001, the middle ball 003 is connected with the tie bar 004, the tie bar 004 is evenly connected in the horizontal direction, the middle ball 003 is a spherical structure, and the fixed head 001 fixes the stress p...

Embodiment 2

[0042] as attached Figure 7 to attach Figure 9 Shown:

[0043] Wherein, the middle ball 003 includes an outer ring g1, a blank holder g2, a blank g3, and a central core g4, the blank g3 and the outer ring g1 are of an integrated structure, and the central core g4 and the outer ring g1 are located on the same axis On the center, the blank holder g2 is against the inner wall of the outer ring g1, the center core g4 is a spherical structure, the outer ring g1 limits the installation range inside, the center core g4 fixes the hard force of the center, the Blankholder g2 supports the supporting force of the outer layer.

[0044]Wherein, the clamping edge g2 includes a hard block 511, an arc body 512, and a limiting edge 513, the hard block 511 and the arc body 512 are an integrated structure, the limiting edge 513 is attached to the outer surface of the arc body 512, and the There are two hard blocks 511, the arc body 512 is an arc structure, the arc body 512 supports the forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com