Copper core low-voltage power cable with armor structure, and manufacturing method

A low-voltage power and copper core technology, which is applied in the copper core low-voltage power cable with armored structure and the manufacturing field, can solve the problems of poor integration between the armored structure and the cable structure, easy deformation of the armored structure, and large resource consumption. The effect of simple processing procedure, enhanced integrity, and reduced cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

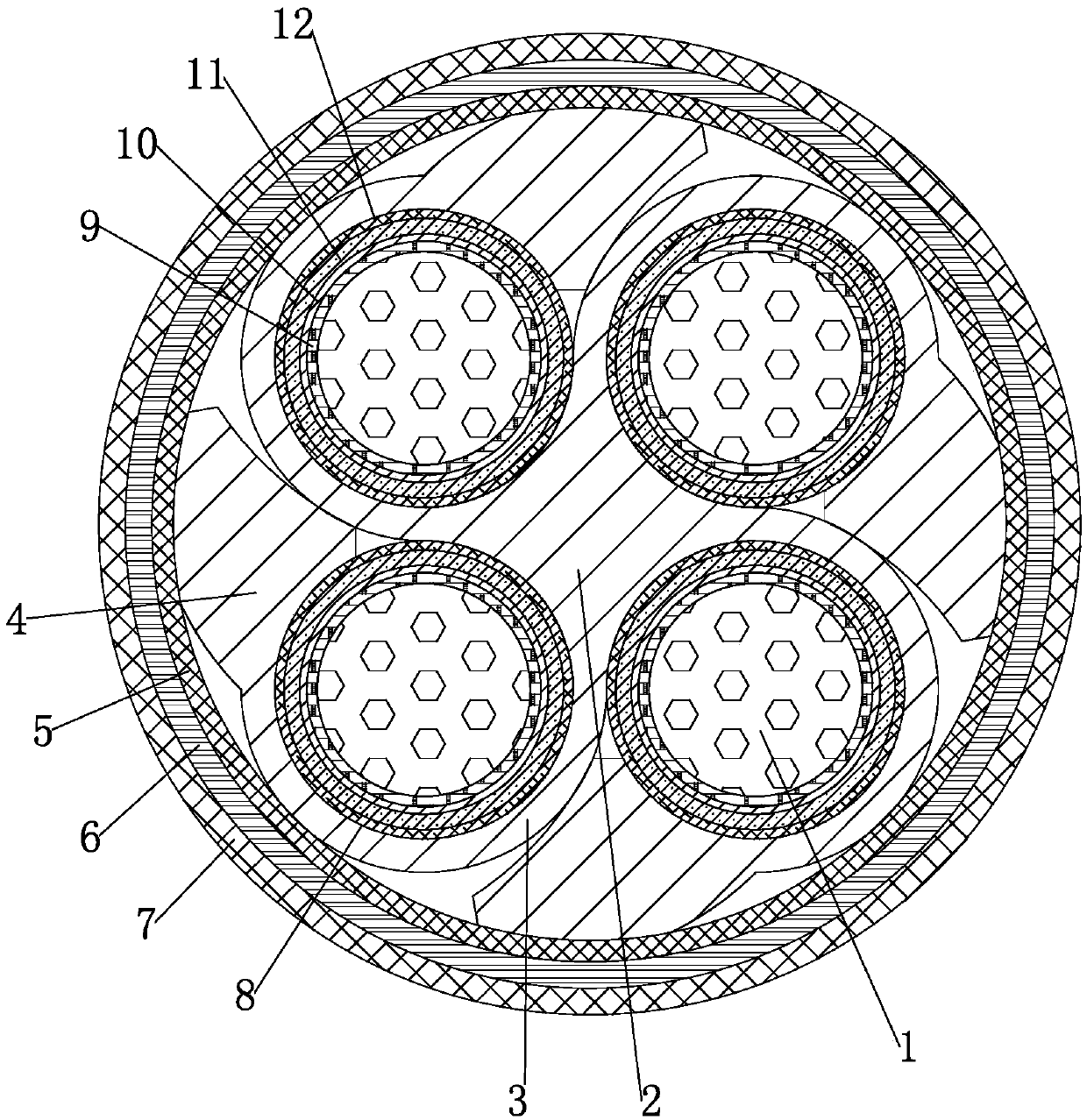

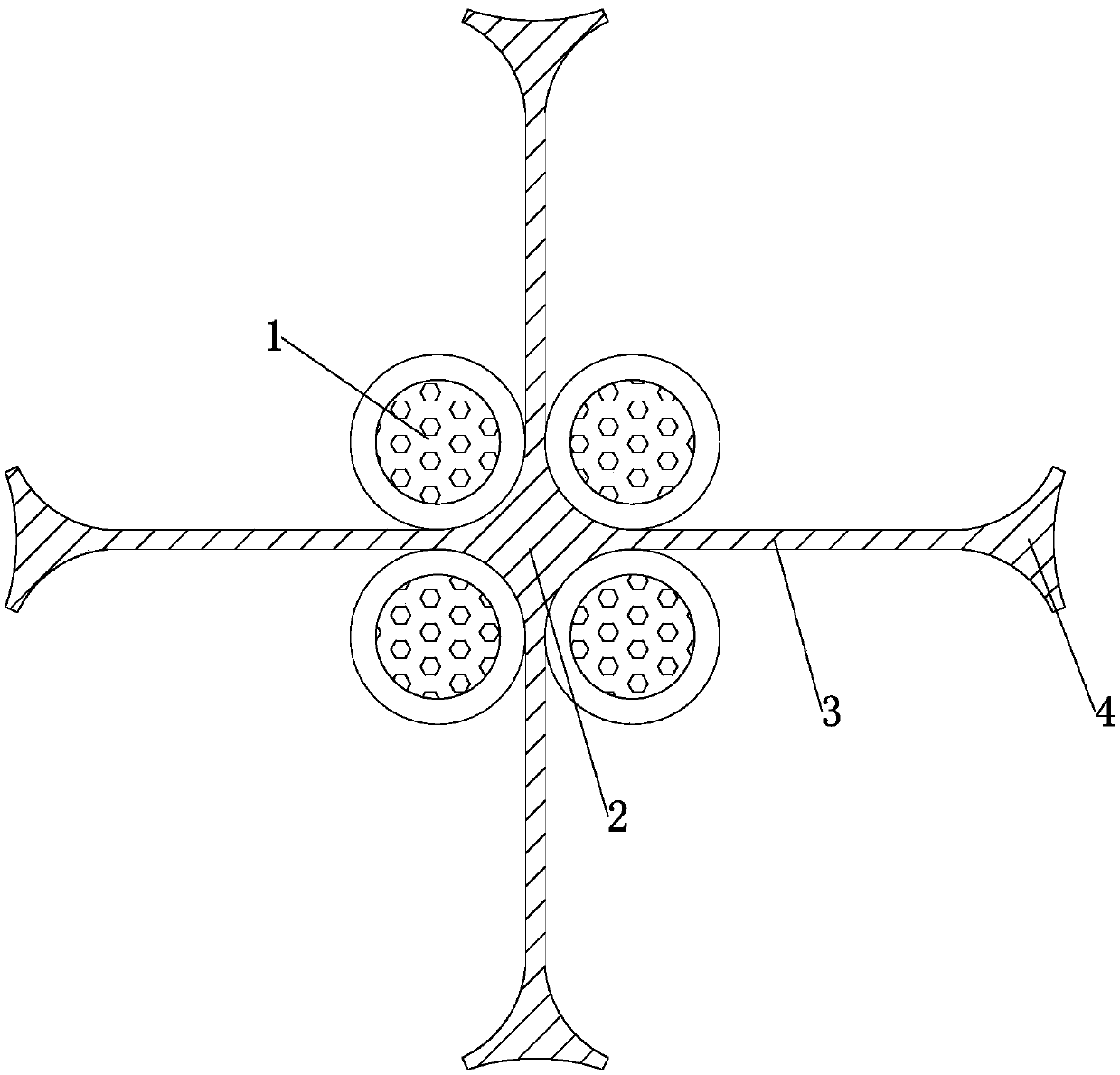

[0036] refer to figure 1 and 2 , which is a copper core low-voltage power cable with an armored structure disclosed by the present invention, which includes a two-part structure of an inner core and an outer protective layer. Among them, the inner core includes copper core conductor 1, support core 2, spacer 3 and support bar 4 and other structures, and the outer protective layer includes three parts: inner sheath 5, aluminum alloy armor layer 6 and outer sheath 7.

[0037] The support core 2 is located at the center of the cable, and four spacers 3 distributed in a cross shape protrude radially from the outside, and the side surface of the support core 2 between the spacers 3 and the spacers 3 is an inwardly concave arc surface, Copper core conductors 1 are arranged between adjacent spacers 3, and the number of copper core conductors 1 and spacers 3 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com