Sensing bulb assembly, heat exchanger and air conditioner

A technology of temperature sensing bulbs and heat exchangers, which is applied to the parts, instruments, thermometers and other directions of thermometers, can solve the problems of poor temperature detection accuracy of temperature sensing bulb components, misalignment and looseness of inserts, etc., so as to avoid the detection of overheating. Or the subcooling degree is incorrect, improve the temperature detection accuracy, avoid the effect of dislocation and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

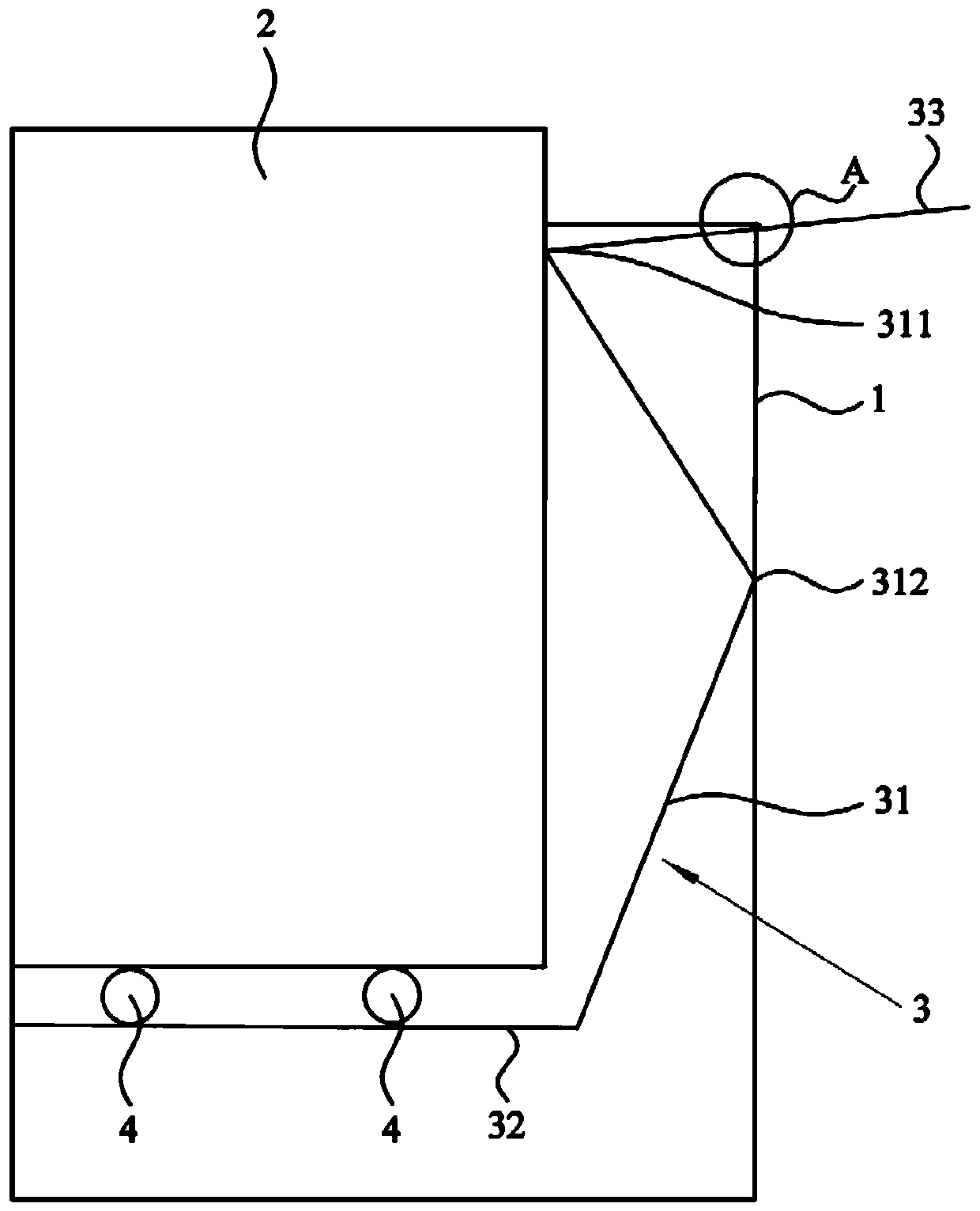

[0042] Such as figure 1 As shown, this embodiment provides a temperature-sensing package assembly, which includes a sleeve 1, a temperature-sensing package 2, and an insert 3, the insert 3 is fixed to the temperature-sensing package 2, and the insert is fixed as one 3 and the temperature-sensing package 2 are arranged in the casing 1, and the insert 3 makes the temperature-sensing package 2 and the casing 1 relatively fixed. By installing the fixed insert 3 and the temperature-sensing package 2 into the sleeve 1, the phenomenon of misalignment and loosening of the insert 3 can be effectively avoided, so that the temperature-sensing package 2 and the inner surface of the sleeve 1 are tightly bonded , the assembled temperature-sensing package assembly has good stability, which can improve the temperature detection accuracy of the temperature-sensing package assembly. In addition, by putting the fixed insert 3 and the temperature-sensing package 2 into the casing 1, the assembly...

Embodiment 2

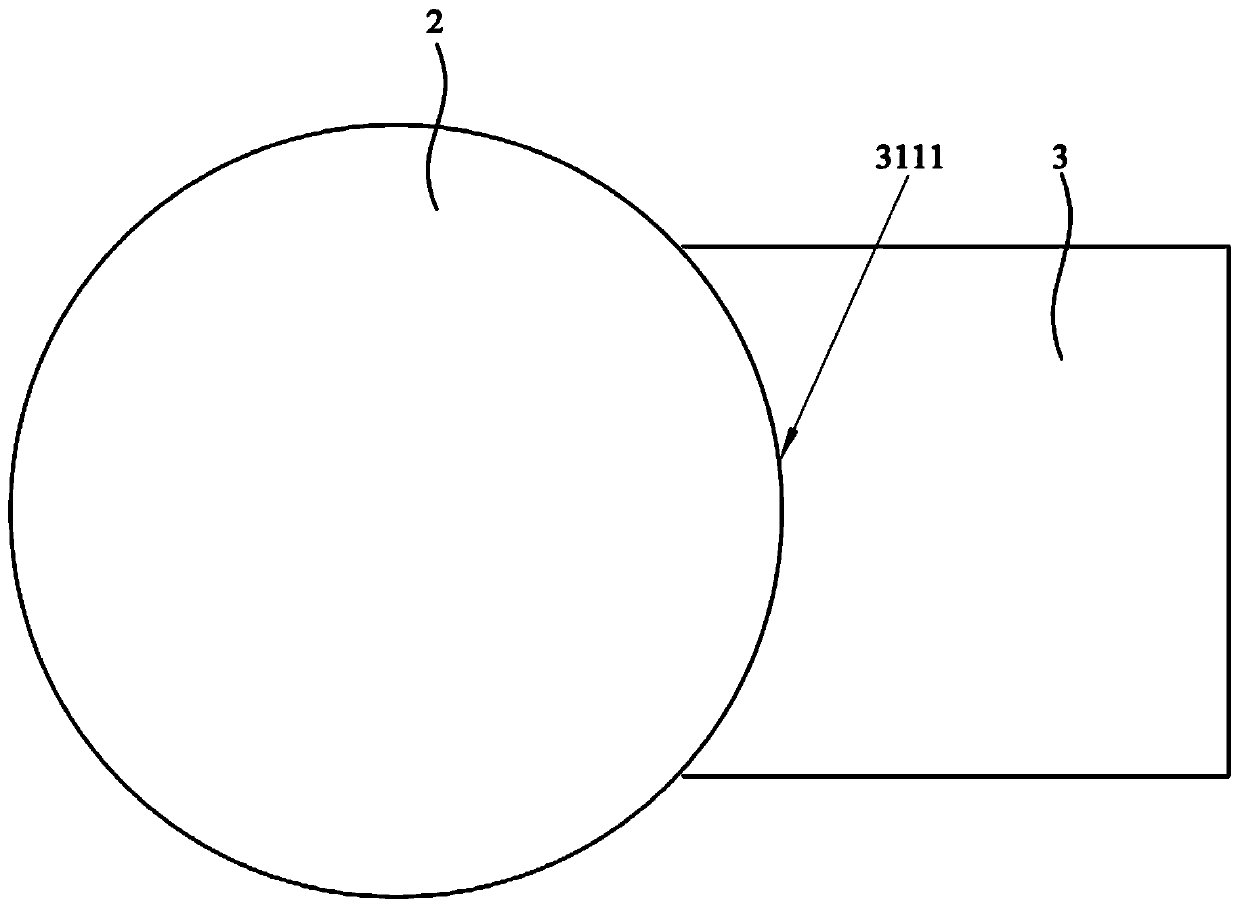

[0053] Such as Figure 5 As shown, the structure of the temperature-sensing package assembly provided in this embodiment is roughly the same as the temperature-sensing package assembly provided in Example 1. The main difference between the two is that the cross-section of the temperature-sensing package 2 in this embodiment is a regular hexagon. The shape and size of the abutment line 3111 where the first protrusion 311 abuts against the outer peripheral surface of the temperature-sensitive package 2 matches the shape and size of the outer peripheral surface of the temperature-sensitive package 2, so that the temperature-sensitive package 2 and the insertion piece 3 can be realized The circumferential direction of the temperature sensing package 2 has better contact effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com