Magnetic steel module, rotor house and rotor assembly

A module and magnetic steel technology, which is applied in the direction of magnetic circuit rotating parts, electric components, magnetic circuits, etc., can solve the problems of magnetic steel modules such as loose fixation, abnormal operation noise or loosening, so as to avoid loosening, Avoid abnormal noise and avoid the effect of bolt loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

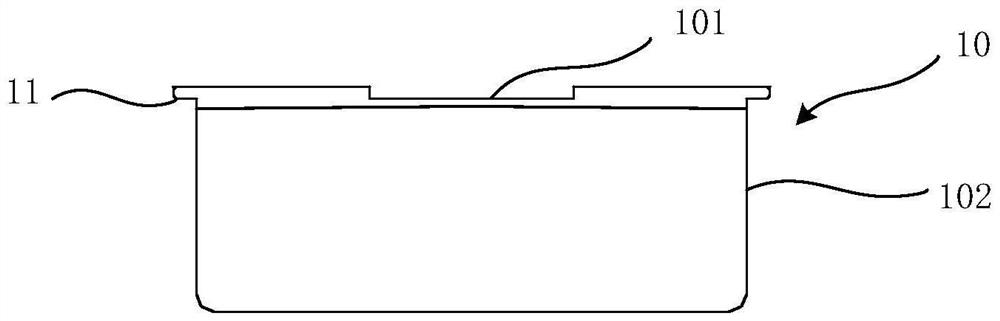

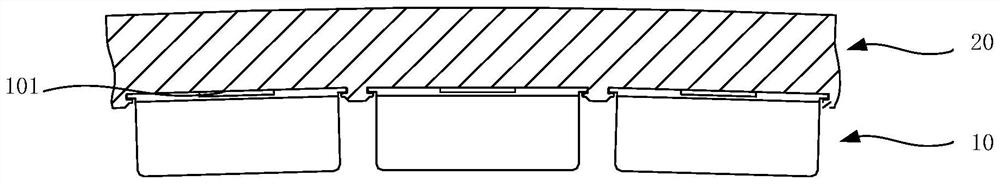

[0053] Such as Figure 1 to Figure 4 As shown, this embodiment provides a rotor assembly 30, the rotor assembly 30 includes a magnetic steel module 10 and a rotor house 20, the magnetic steel module 1 is fixed on the rotor house 20, and the magnetic steel module 10 includes a The substrate 15 in contact with the yoke surface, the substrate 15 is made of magnetically permeable material, and has a first groove 101 on the side facing the yoke surface, the first groove 101 is connected to the magnetic steel module 10 and the yoke surface A gap is formed between them to reduce the contact area between the yoke surface and the substrate 15 . The magnetic steel module 10 also includes a cover plate 12, a magnetic steel 13, a magnetic steel frame 14 and a silicon steel part (not shown in the figure), wherein the silicon steel part is arranged between the magnetic steel 13 and the base plate 15, and the upper and lower parts of the silicon steel part The two ends are respectively in c...

Embodiment 2

[0066] This embodiment provides a rotor assembly 30 , which adopts the same principle as Embodiment 1. The difference is that in this embodiment, grooves are made on the yoke surface of the rotor house 20 , while the magnetic steel module 10 does not have grooves.

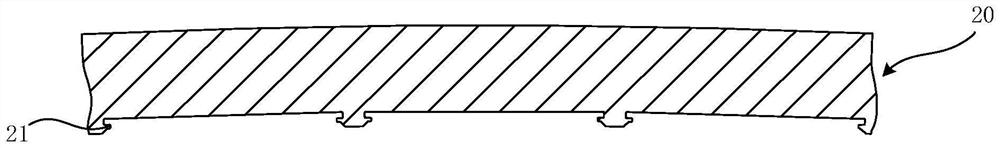

[0067] Such as Figure 5 to Figure 8 As shown, a rotor house 20, the rotor house 20 includes a yoke surface in contact with the magnetic steel module 10, a second groove 201 is opened on the yoke surface, and the second groove 201 makes the yoke surface and the magnetic steel mold Gaps are formed between the groups 10 to reduce the contact area between the yoke face and the substrate 15 .

[0068] In this embodiment, there is one second groove 201 , and the shape of the second groove 201 projected on the yoke surface is a waist-shaped groove extending along the axis of the rotor house 20 . It should be noted that the number, shape and size of the grooves are not specifically limited here, and it can be multiple gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com